Precautions for Correct Use

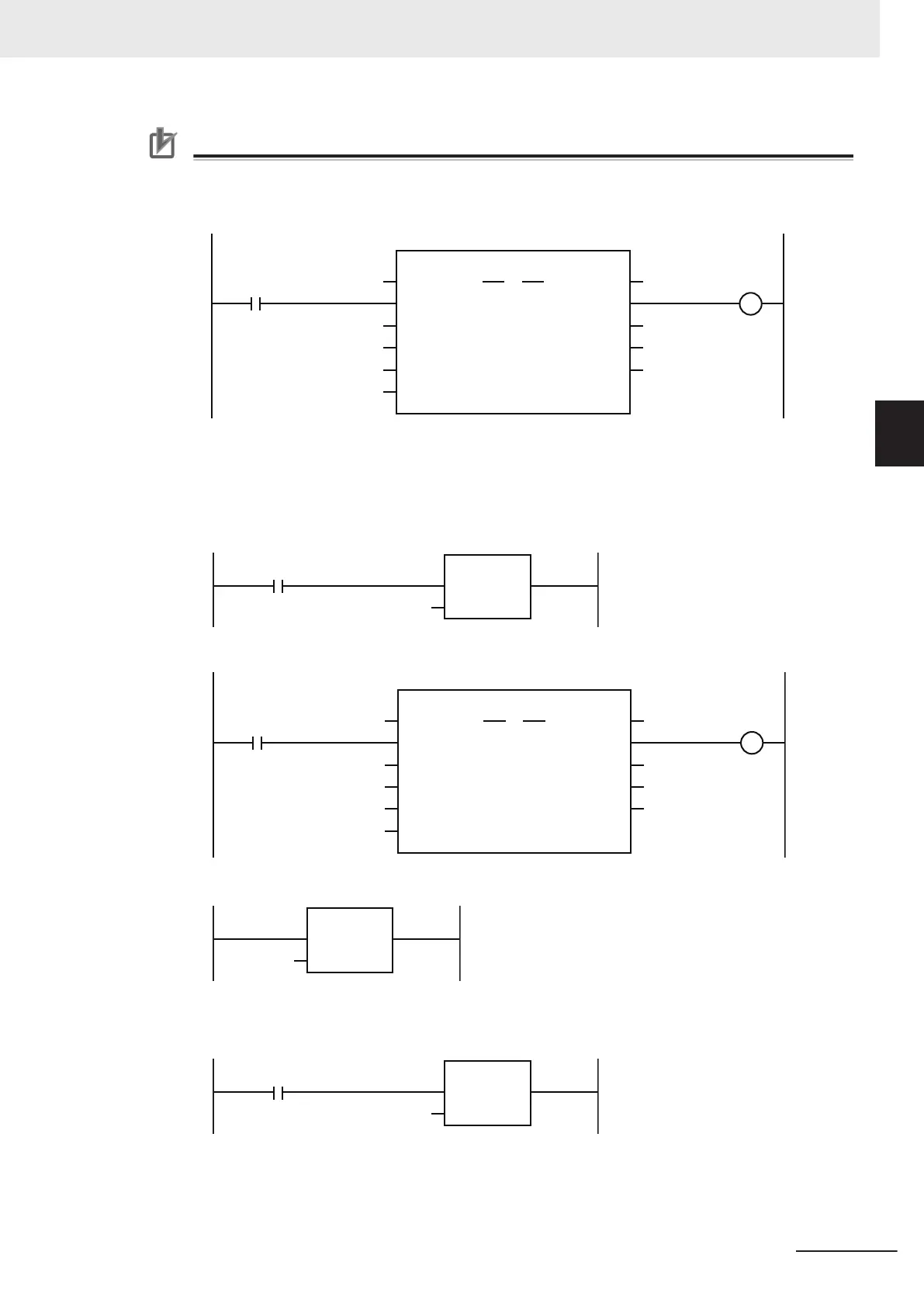

• When creating a ladder diagram program, you must connect the PositiveEnable (Positive Di-

rection Enable) input variable to the left bus bar and specify a variable for the NegativeEnable

(Negative Direction Enable) input variable as shown below

.

Positiv

eEnable

ErrorID

MC_MoveJog_instance

Error

MC_MoveJog

Axis Axis

Busy

CommandAbort

ed

NegativeEnable

V

elocity

Acceleration

Deceleration

MC_Axis000

POS_EN

NEGA_EN

J_ERRID

VEL

ACC

DEC

J_CA

J_ERR

J_DONE

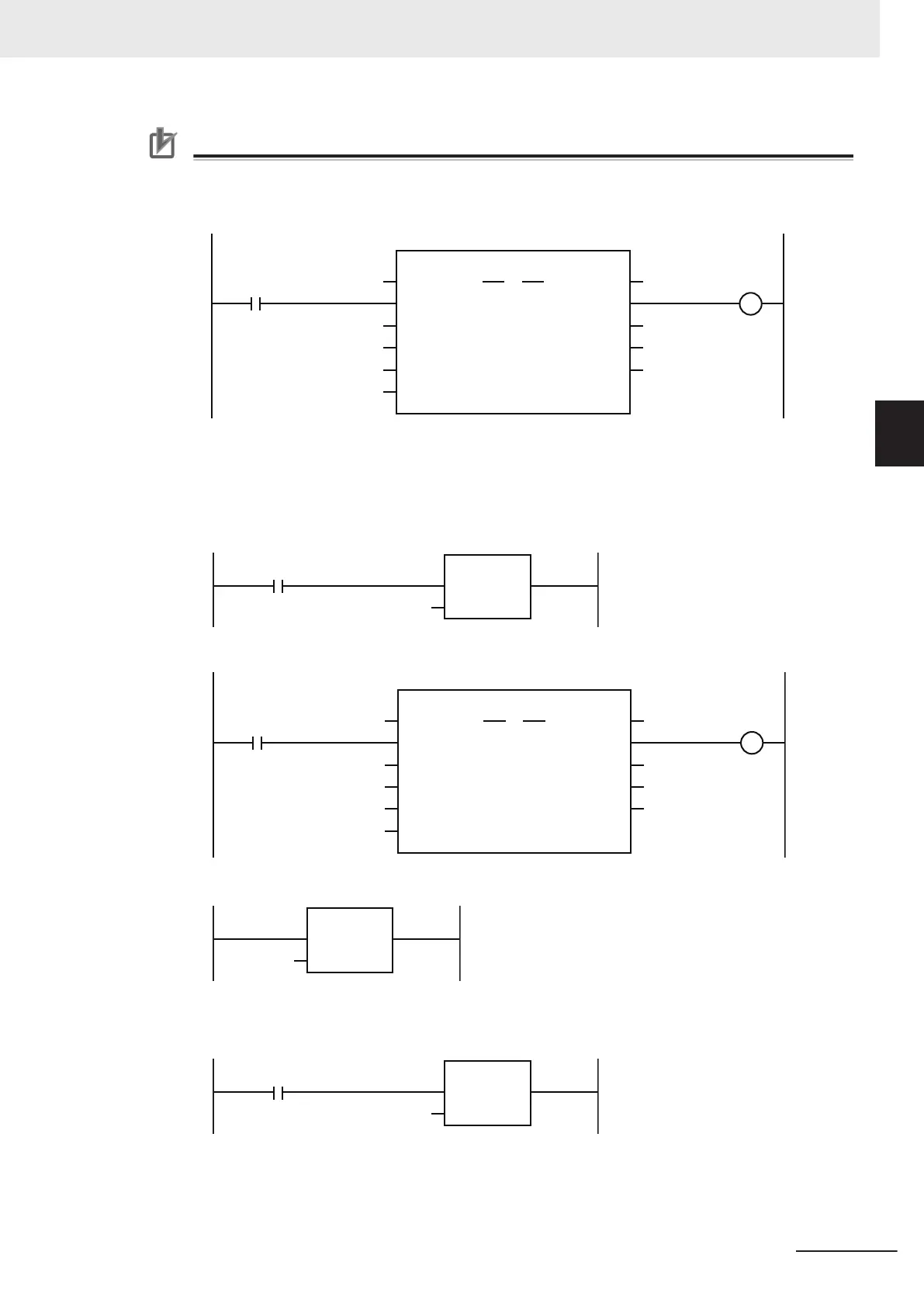

To use the master control instructions (MC and MCR) for the MC_MoveJog (Jog) instruction,

do not program the instructions as shown below

. If you do, master control is applied only to

PositiveEnable (Positive Direction Enable), i.e., it is not applied to NegativeEnable (Negative

Direction Enable).

MC_On

MCNo

MC

In

0

Master control started.

PositiveEnable

ErrorID

MC_Mo

veJog_instance

Error

MC_MoveJog

Axis Axis

Busy

CommandAbortedNegativeEnable

V

elocity

Acceleration

Deceleration

MC_Axis000

POS_EN

NEGA_EN

J_ERRID

VEL

ACC

DEC

J_CA

J_ERR

J_DONE

MC_MoveJog Instruction

MCNo

MCR

In

0

Master control ended.

Always use the master control instructions for the MC_Power instruction.

MC_On

MCNo

MC

In

0

Master control started.

3 Axis Command Instructions

3-11

NY-series Motion Control Instructions Reference Manual (W561)

MC_MoveJog

3

Function

Loading...

Loading...