4 — Component Identification

22

920515770_J

Vision® 1300 Series

Operator Manual

4.11 Electrical Box

The electrical box is located on mechanical core. Electrical box contains the central processor Unit (CPU) and controls

washer/disinfector operation.

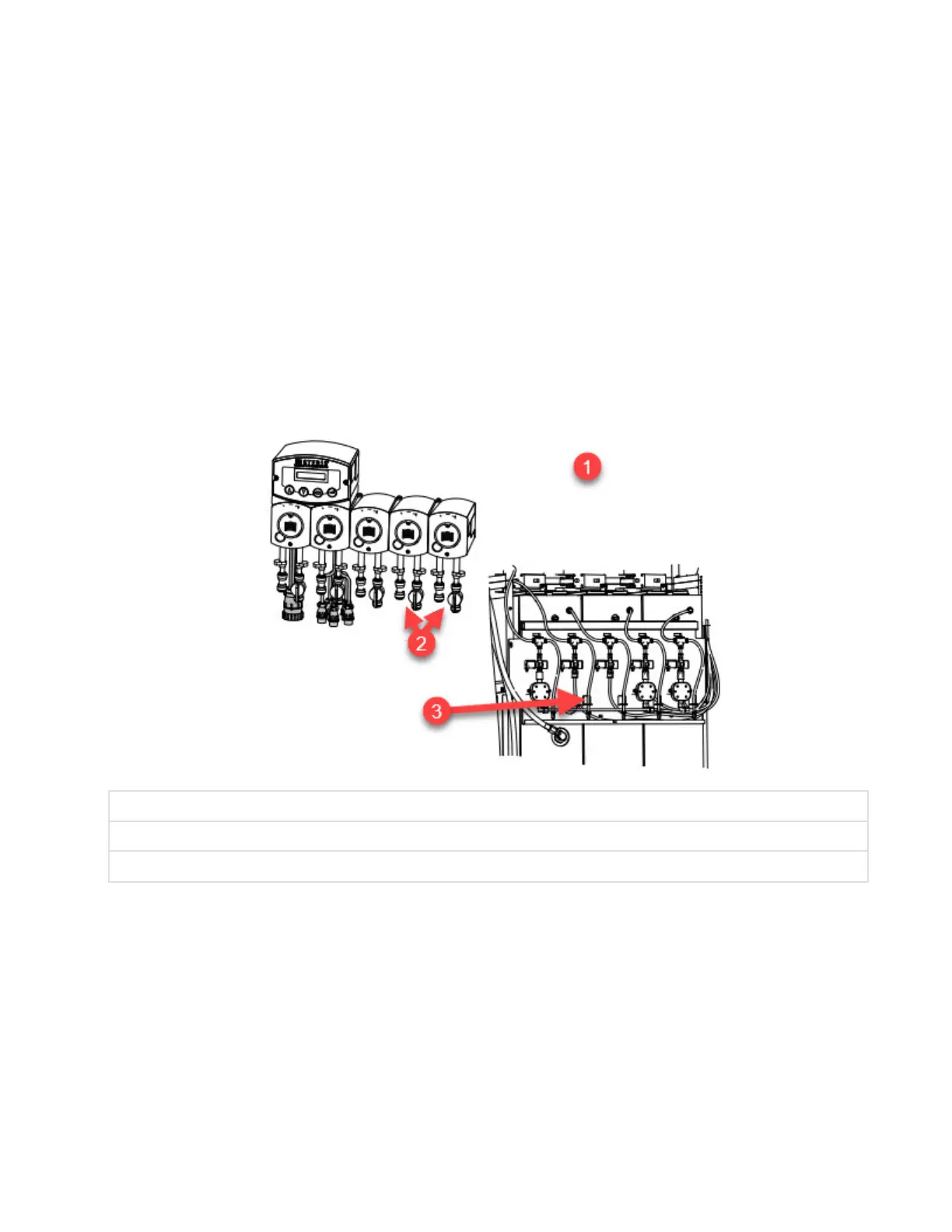

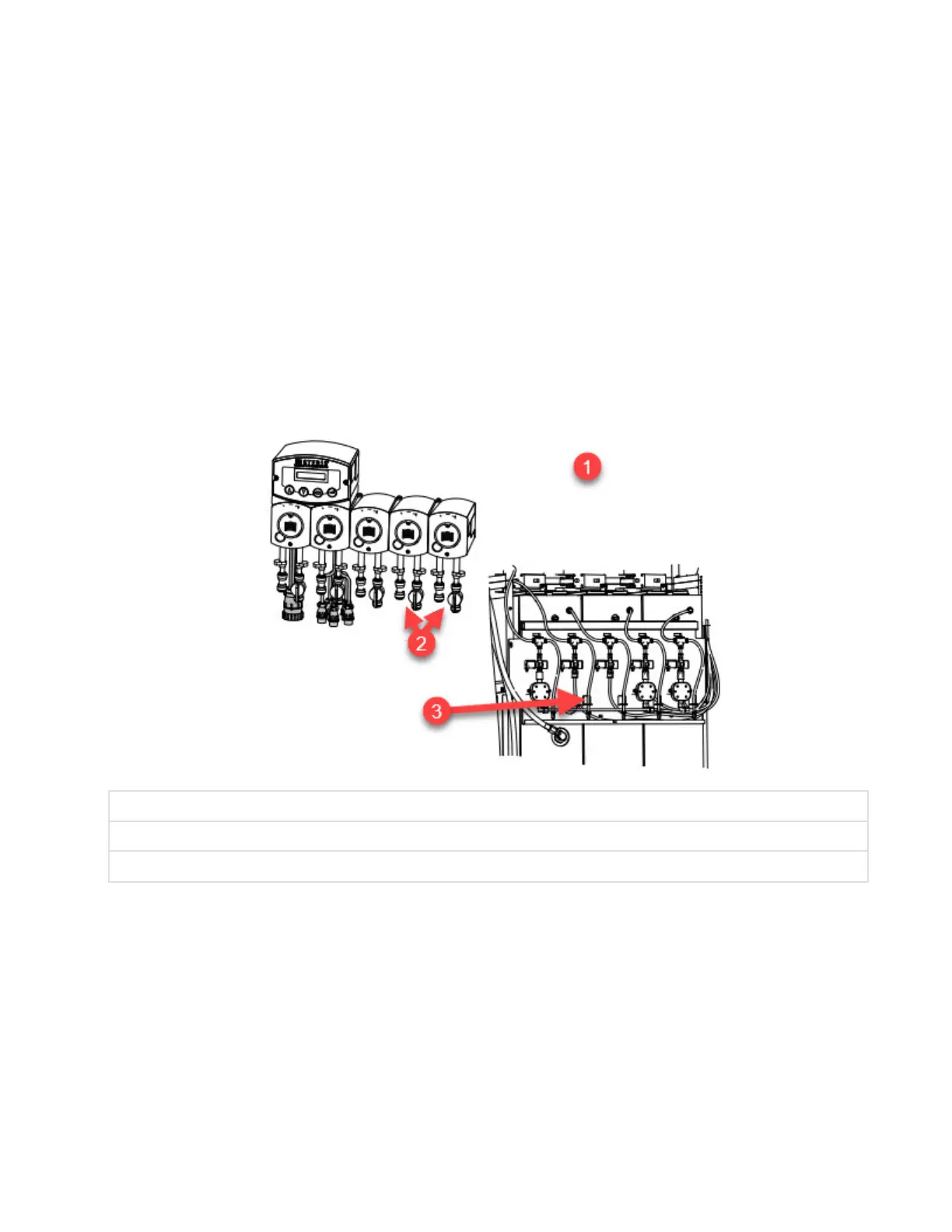

4.12 Chemical Dispensing System

Three chemical injection pumps are included with a standard washer/disinfector. Up to two additional chemical

injection pumps are included when Instrument Wash and/or Third Reservoir option is present. The chemical injection

pump assembly is installed remotely on the wall, near the chemical containers.

• One chemical pump (standard) is dedicated to the alkaline or neutral detergent to be injected in the wash

reservoir(s); one or two additional injection pump(s) can be present;

• One chemical pump is dedicated to the rinse aid to be injected in the thermal rinse reservoir;

• One chemical pump is dedicated to the Liquid Descaler Acid-Based Scale Remover to be injected in the chamber

during the DECONTAM cycle.

The chemical dosing system allows the use of the Prolystica® Ultra Concentrate chemicals. Each ultra

concentrated product is ten times the concentration of a traditional product, therefore ten times less chemical is

injected to properly process the cycles (refer to Section 3.8, Using Prolystica Ultra Concentrate Chemicals).

1. Chemical Dosing System (Wall-Mounted Near Chemical Supply)

2. Optional

3. Chemical Dispensing Devices (on Reservoir Mechanical Core)

.

The chemical dispensing devices, including valves, sampling ports and flowmeters, are installed on a mounting

bracket attached to the reservoirs on the mechanical core.

4.13 Drying Pre-Filter and HEPA Filter

An air inlet pre-filter and HEPA filter are located on mechanical core drying section. Incoming air passes through the

filter(s) to prevent any contamination of the load inside the chamber.

The pre-filter retains gross airborne particles while HEPA filter retains very fine airborne particles.

Loading...

Loading...