7 — Routine Maintenance

117

Operator Manual

Vision® 1300 Series

920515770_J

1. Regular service and maintenance MUST be performed only by STERIS or a STERIS-trained technician. Any work

performed by inexperienced or unqualified persons or the installation of unauthorized parts could cause

personal injury, invalidate the warranty o result in costly damage.

2. Under no circumstances should this equipment be serviced without the Maintenance Manual. The Maintenance

Manual (P764334114) can be purchased by contacting STERIS Customer Service.

3. A detailed Preventive Maintenance schedule and replacement parts list can be found in the Maintenance Manual.

The Maintenance Manual can be purchased by contacting STERIS Customer Service.

4. Preventive Maintenance is essential in keeping this equipment in optimal working condition. STERIS

recommends establishing an annual maintenance agreement with STERIS service.

7.3 Routine Maintenance

The sample routine maintenance guide (Table 7-1) included in this section should be used as a guideline for determining

the frequency. This proves useful in helping ensure proper maintenance of your washer/disinfector.

Maintenance procedures included inTable 7-1 are to be performed by the Operator at the indicated frequencies. The

indicated frequencies are minimums and can be changed if washer/disinfector use warrants.

If a problem occurs, refer to Troubleshooting Section.

Refer to Section 9, Replacement Parts and Products , for recommended spare parts list.

For detailed Preventive Maintenance procedures to be performed by a STERIS-trained service technician, refer to

Preventive Interval-Based Checklist included in corresponding Maintenance Manual.

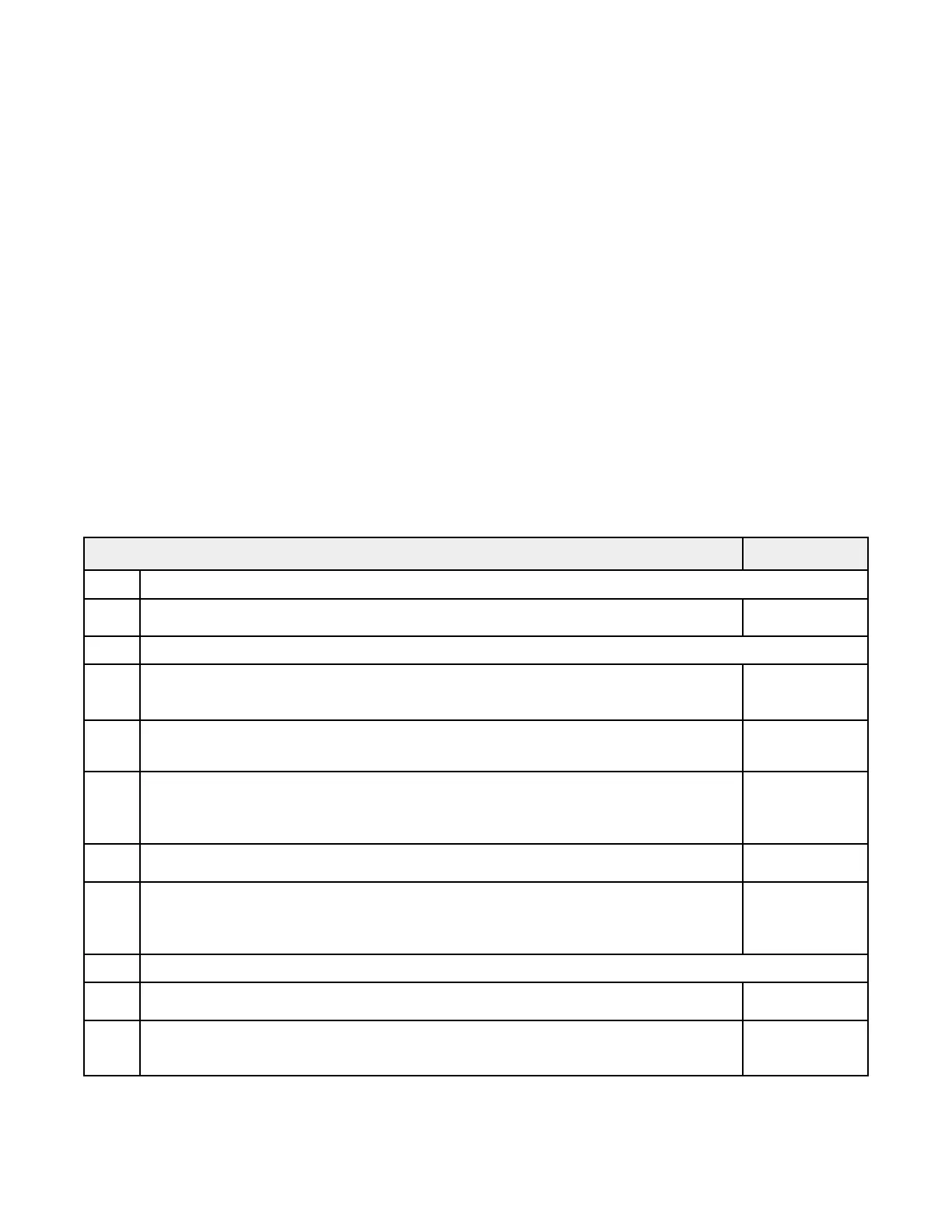

Table 7-1. Routine Maintenance — Checklist

Usage and utility conditions may require more or less frequent inspections. Subsystem

1.0

ONCE PER DAY

Clean debris screen in chamber (see Section 7.4, Debris Screen).

Chamber

2.0

ONCE PER WEEK

2.1

Inspect traveler spray arm assemblies for clogged holes. Clean if necessary (see Section

7.9, Traveler Spray Arm Assemblies).

Chamber

2.2

While cycle is in progress, look through chamber door window to verify traveler spray

arm assemblies for free movement.

Chamber

2.3

Verify if DECONTAMINATION Cycle Warning message is displayed on control. Remove

hard water deposits from interior of chamber (use DECONTAM cycle; see Section 7.6,

Decontam Cycle).

Chamber

2.5

Clean washer/disinfector exterior (see Section 7.5, Clean Washer/Disinfector Exterior).

Chamber

2.6

Inspect all spray arms on Vision CW Instrument Washing Rack for obstruction and free

rotation. Clean spray arms (see Section 7.10, Vision CW Instrument Washing Manifolded Rack

Spray Arm Assemblies).

Instrument Rack

3.0

ONCE PER MONTH

3.1

Brush each door gasket to clean, then disinfect using a germicidal detergent.

Door Assembly

3.2

Verify door gasket for wear and tear. Verify gasket is properly inserted in door frame. If

gasket needs to be replaced, contact STERIS

*

or Customer’ s Maintenance Service.

Door Assembly

Loading...

Loading...