ENGINE GENERAL INFORMATION AND DIAGNOSIS (M13 ENGINE) 6-2-109

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Drive vehicle under freeze frame data condition as noted for 1 min. or more.

4) Stop vehicle and check DTC and pending DTC.

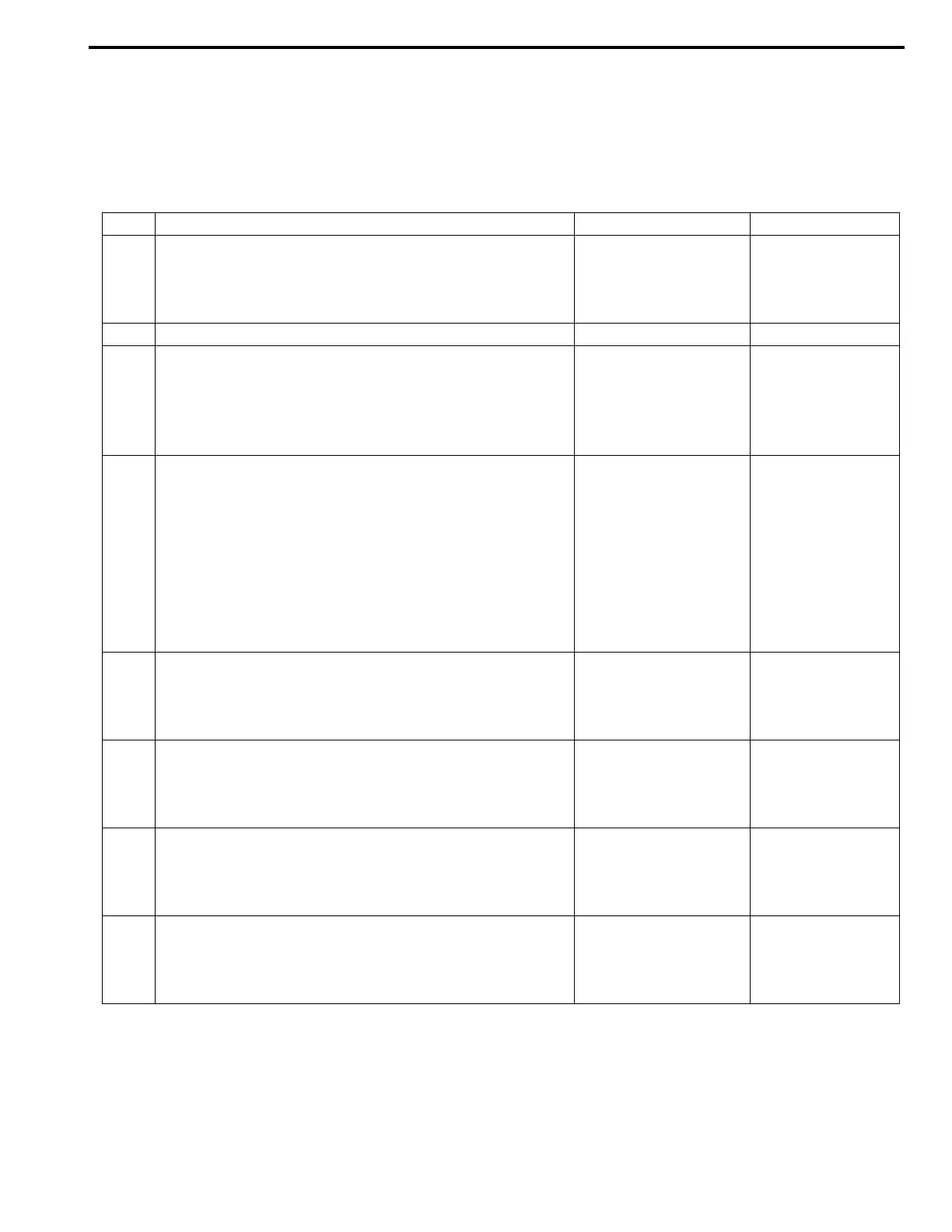

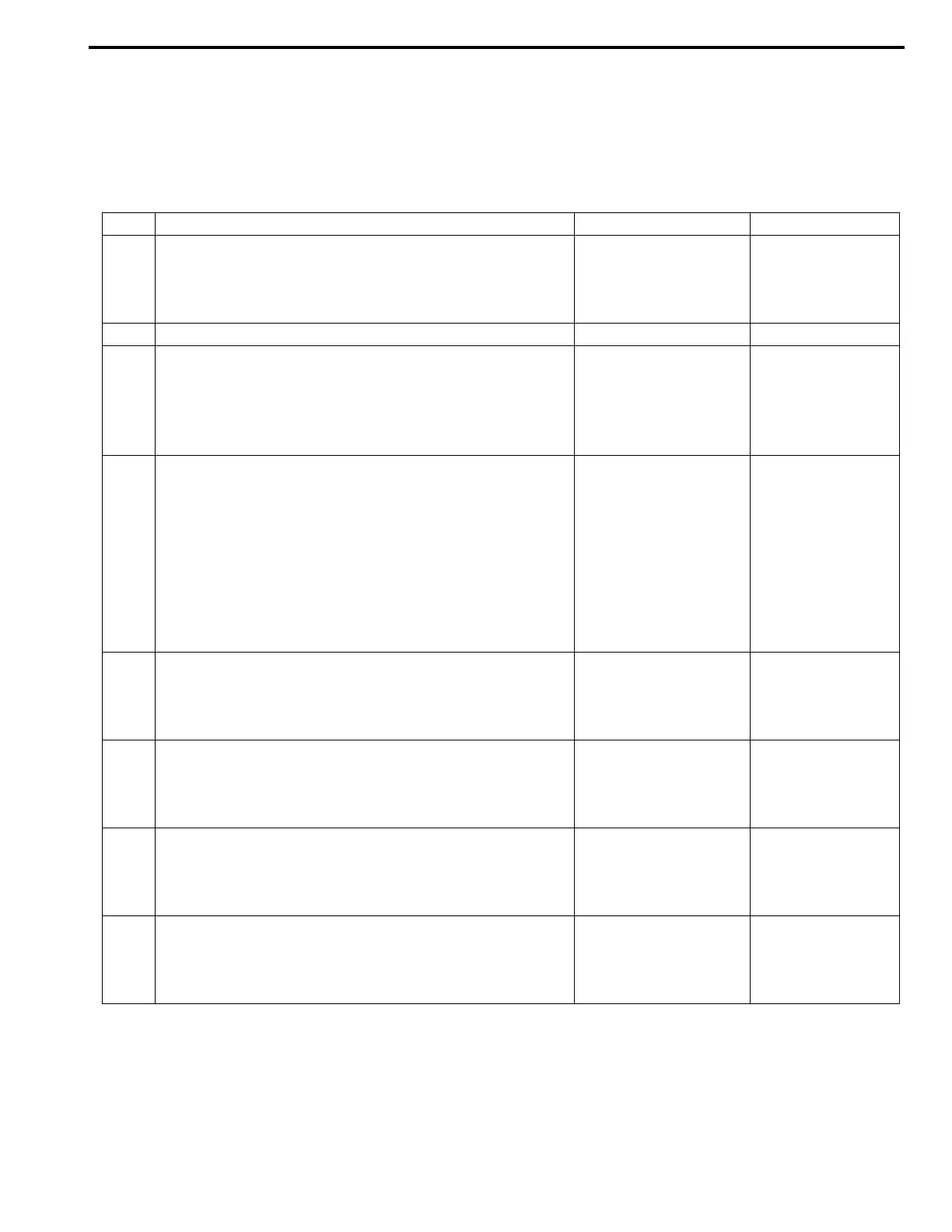

Troubleshooting

Step Action Yes No

1Was “Engine and Emission Control System Check” per-

formed?

Go to Step 2. Go to “Engine and

Emission Control

System Check” in

this section.

2 Does fuel level meter indicate “E” level (empty)? Add fuel and recheck. Go to Step 3.

3 Ignition system inspection.

1) Check spark plug and ignition spark of cylinder

where misfire occurs, referring to “Spark Plugs

Inspection” and “Ignition Spark Test” in Section 6F2.

Is it in good condition?

Go to Step 4. Faulty ignition coil,

wire harness,

spark plug or other

system parts.

4 Fuel injector circuit check.

1) Using sound scope, check each injector operating

sound at engine cranking or idling.

Do all injectors make operating sound?

Go to Step 5. Check coupler con-

nection and wire

harness of injector

not making operat-

ing sound and

injector itself.

If OK, substitute a

known-good ECM

and recheck.

5 Fuel pressure inspection.

1) Check fuel pressure referring to “TABLE B-3 Fuel

Pressure Check” in this section.

Is check result satisfactory?

Go to Step 6. Repair or replace.

6 Fuel injector inspection.

1) Check fuel injector(s) referring to “Fuel Injector

Inspection” in Section 6E2.

Is check result satisfactory?

Go to Step 7. Replace.

7 Ignition timing inspection.

1) Check ignition timing referring to “Ignition Timing

Inspection” in Section 6F2.

Is check result satisfactory?

Go to Step 8. Check related sen-

sors.

8 EGR system inspection.

1) Check EGR system referring to “EGR Valve Inspec-

tion” in Section 6E2.

Is check result satisfactory?

Go to Step 9. Repair or replace.

Loading...

Loading...