AUTOMATIC TRANSAXLE (M13 ENGINE) 7B1-143

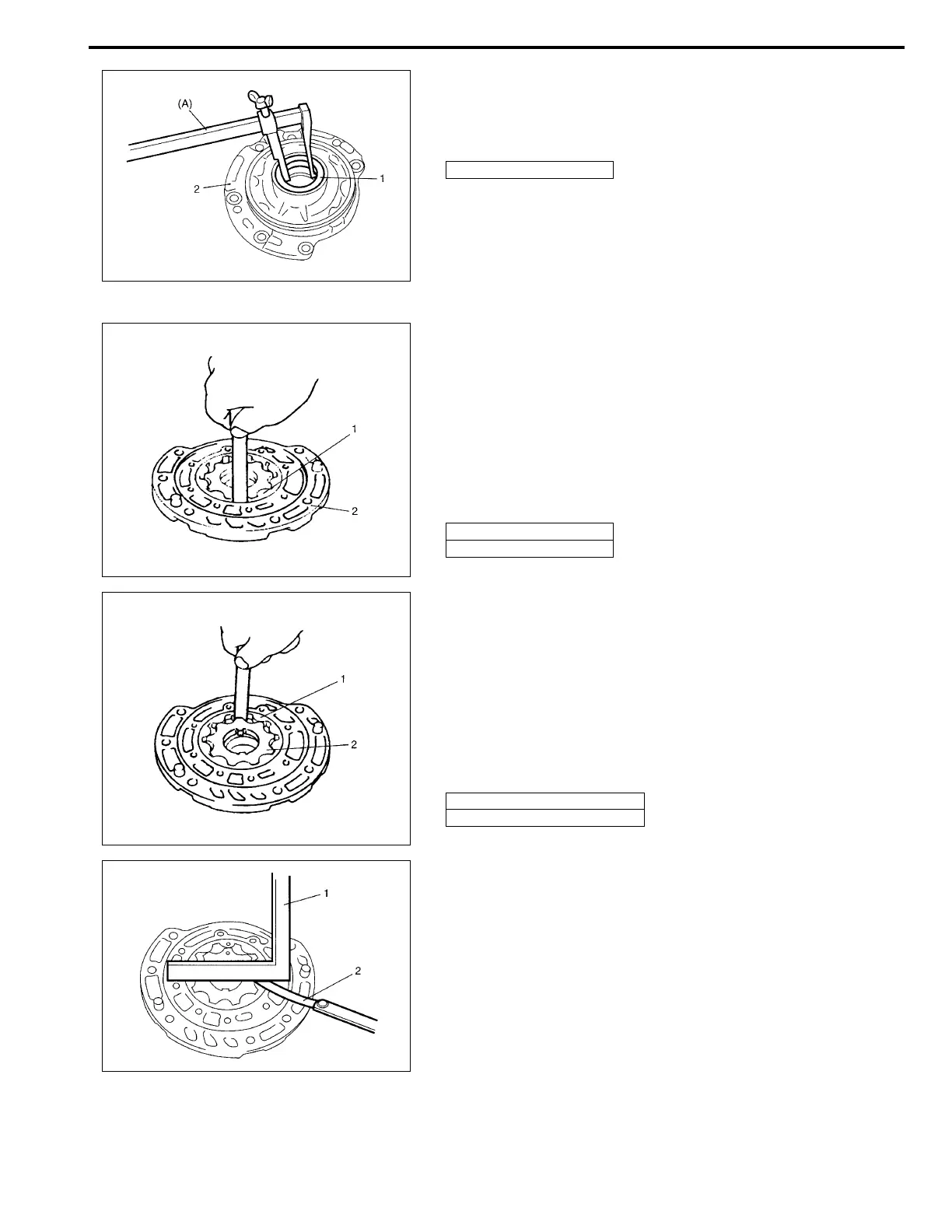

3) Remove oil seal (1) using special tool.

Special tool

(A): 09913-50121

Inspection

1) Check body clearance of driven gear.

Push driven gear to one side of body Using feeler gauge,

measure clearance between driven gear and body.

If clearance exceeds its standard value, replace oil pump

assembly.

Clearance between oil pump driven gear and oil pump

body

Standard: 0.1 – 0.17 mm (0.0039 – 0.0067 in.)

2) Check tip clearance between drive and driven gear.

Using a feeler gauge, measure clearance between drive and

driven gear tips.

If clearance exceeds its standard value, replace oil pump

assembly.

Tip clearance between oil pump drive gear and oil pump

driven gear

Standard: 0.07 – 0.15 mm (0.0028 – 0.0059 in.)

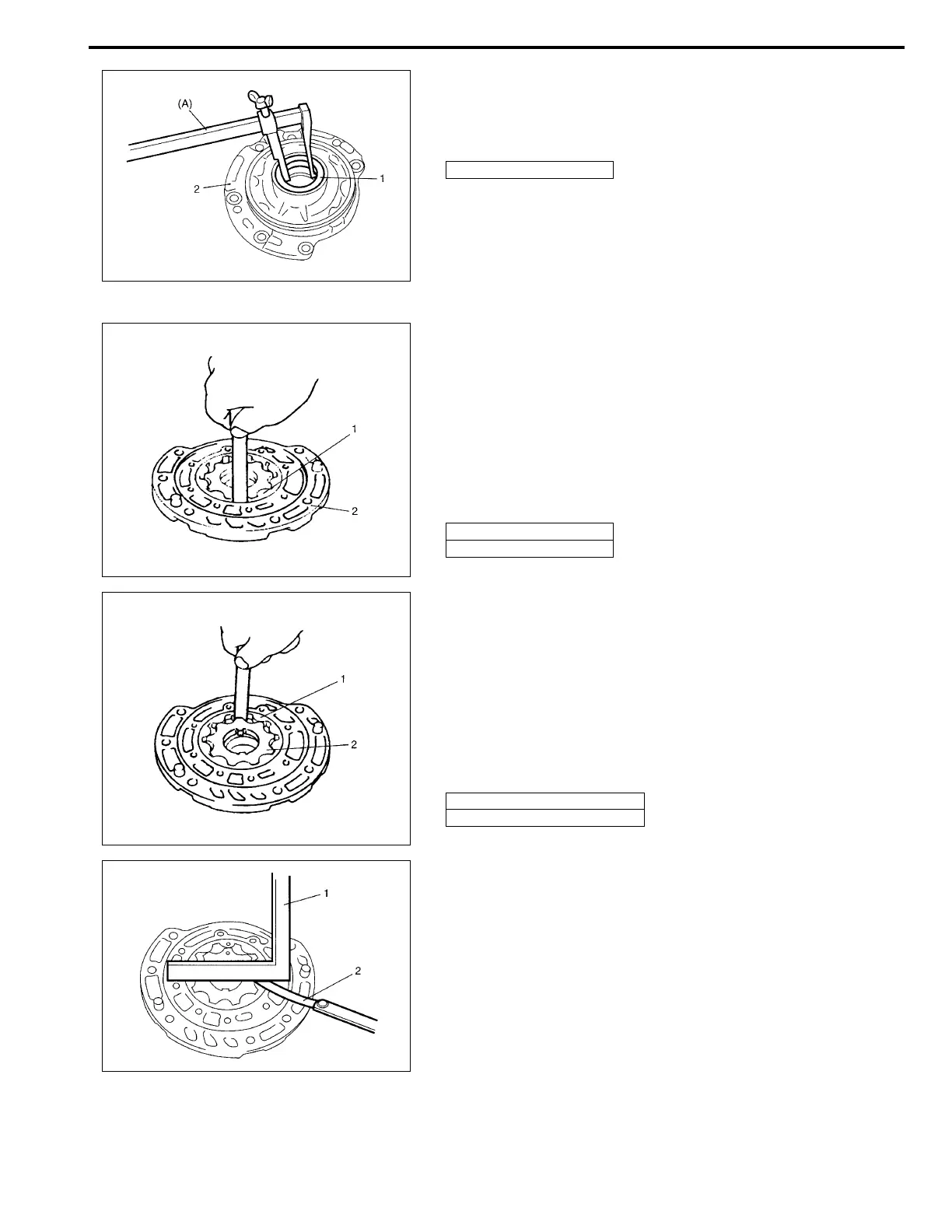

3) Check side clearance of both gears.

Using straightedge (1) and feeler gauge (2), measure side

clearance between gears and pump body.

If clearance exceeds its standard value, replace oil pump

assembly.

Side clearance between gears and oil pump body

Standard: 0.02 – 0.05 mm (0.0008 – 0.0019 in.)

2. Oil pump body

1. Oil pump driven gear

2. Oil pump body

1. Oil pump driven gear

2. Oil pump drive gear

Loading...

Loading...