6A2-54 ENGINE MECHANICAL (M13 ENGINE)

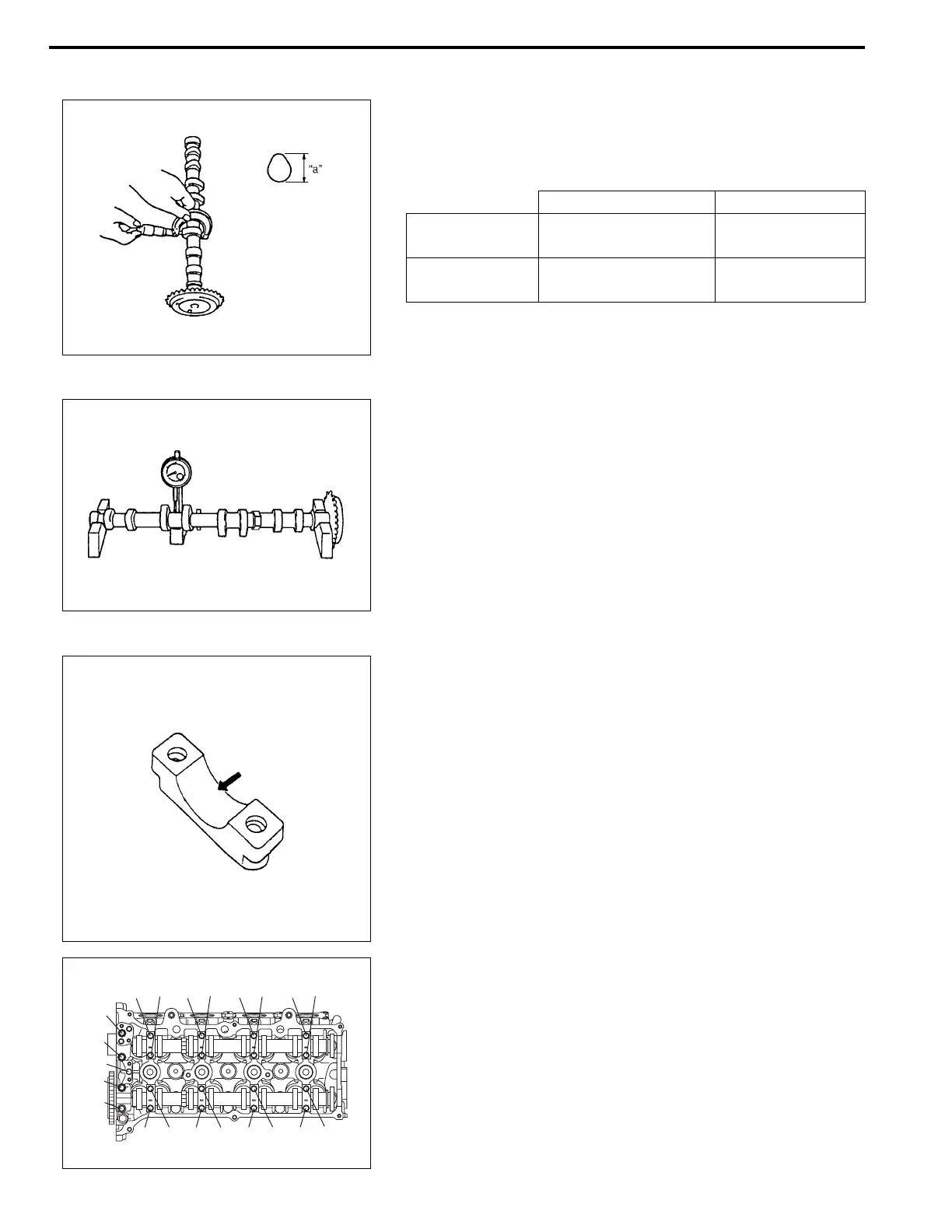

Cam wear

Using a micrometer, measure cam height “a”. If measured height

underruns its limit, replace camshaft.

Cam height “a” of camshaft

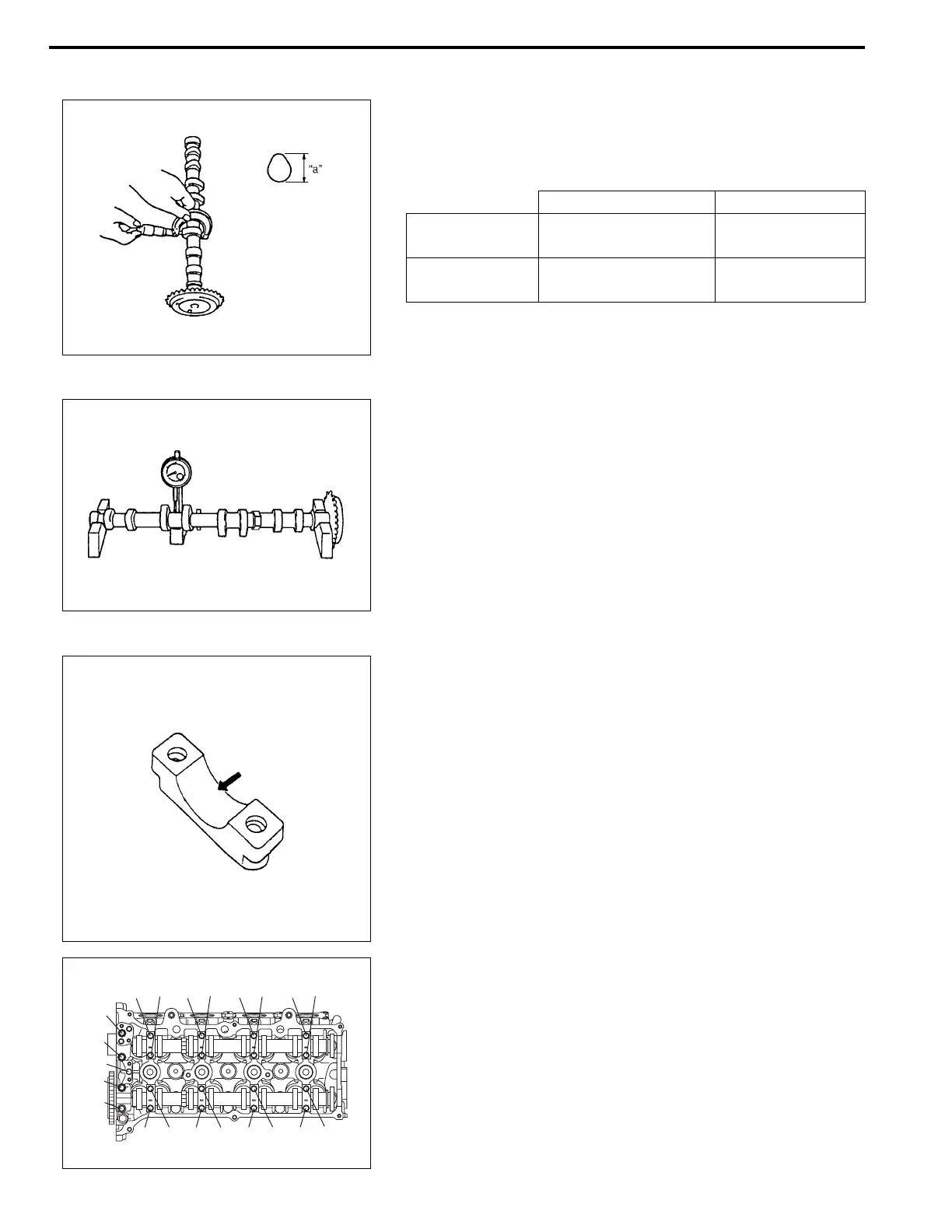

Camshaft runout

Set camshaft between two “V” blocks, and measure its runout by

using a dial gauge.

If measured runout exceeds limit, replace camshaft.

Camshaft runout limit

: 0.10 mm (0.0039 in.)

Camshaft journal wear

Check camshaft journals and camshaft housings for pitting,

scratches, wear or damage.

If any malcondition is found, replace camshaft or cylinder head

with housing. Never replace cylinder head without replacing hous-

ings.

Check clearance by using gaging plastic. Checking procedure is

as follows.

1) Clean housings and camshaft journals.

2) Remove all tappets with shims.

3) Install camshafts to cylinder head.

4) Place a piece of gaging plastic to full width of journal of cam-

shaft (parallel to camshaft).

5) Install camshaft housing.

6) Tighten camshaft housing bolts in such order as indicated in

figure a little at a time till they are tightened to specified

torque.

Tightening torque

Camshaft housing bolt

(a): Tighten 11 N·m (1.1 kg-m, 8.0 lb-ft) by the specified

procedure.

Standard Limit

Intake cam 44.929 – 45.089 mm

(1.769 – 1.775 in.)

44.80 mm

(1.764 in.)

Exhaust cam 44.399 – 44.559 mm

(1.748 – 1.754 in.)

44.28 mm

(1.743 in.)

NOTE:

Do not rotate camshaft while gaging plastic is installed.

“10”

“9”

“2”“1”,(a) “6”

“5”“14”“13”

“20”

“17”

“19”

“18”

“21”

“12”

“11”

“4”“3”“8”

“7”“16”“15”

Loading...

Loading...