ENGINE GENERAL INFORMATION AND DIAGNOSIS (M13 ENGINE) 6-2-113

DTC Confirmation Procedure

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Crank engine for 3 – 5 sec.

4) Check DTC and pending DTC.

Troubleshooting

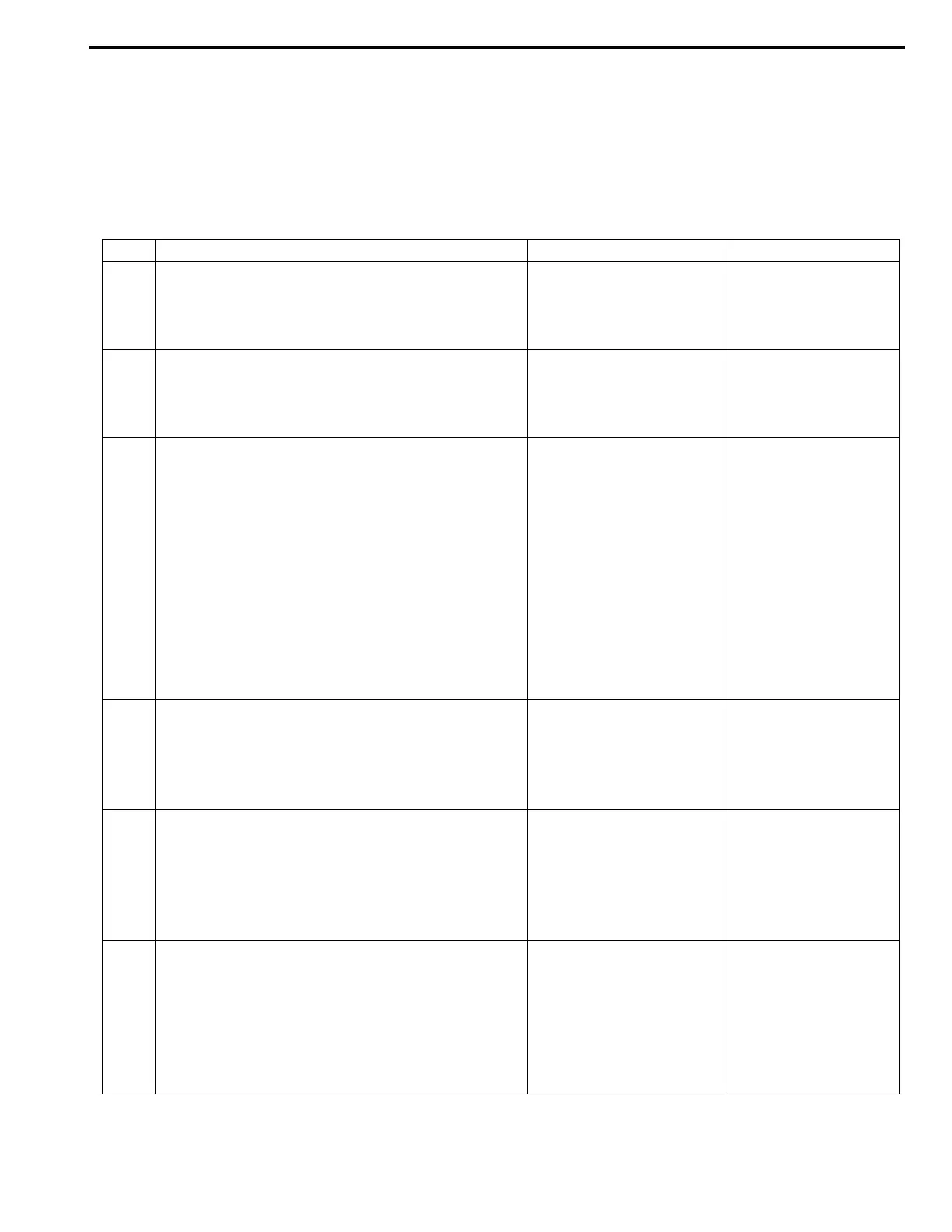

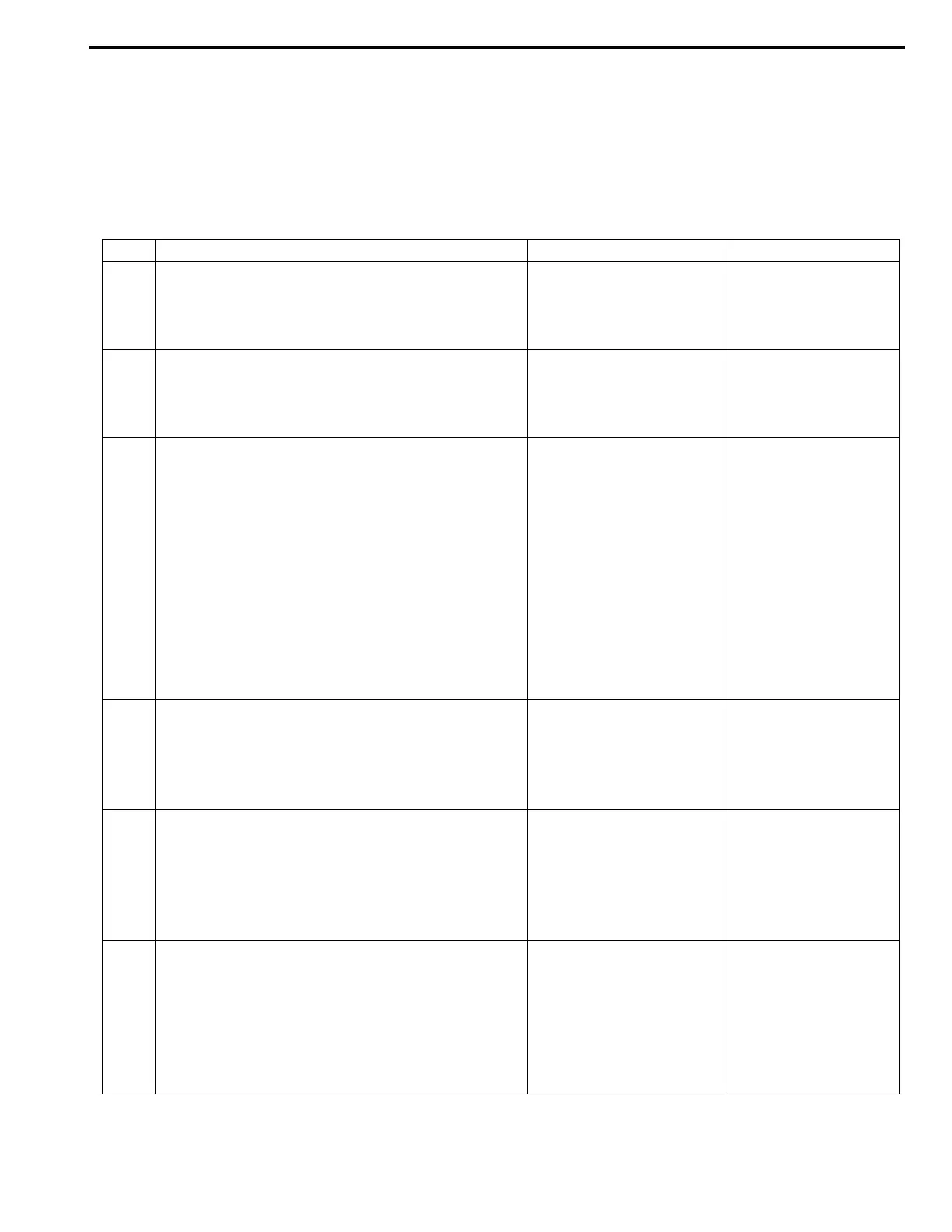

Step Action Yes No

1Was “Engine and Emission Control System

Check” performed?

Go to Step 2. Go to “Engine and

Emission Control Sys-

tem Check” in this sec-

tion.

2 Check CKP sensor and connector for proper

installation.

Is CKP sensor installed properly and connector

connected securely?

Go to Step 3. Correct.

3 Check Wire Harness and Connection.

1) Disconnect connector from CKP sensor.

2) Check for proper connection to CKP sensor at

“BLK/RED”, “PNK” and “BLK” wire terminals.

3) If OK, turn ignition switch ON and check for

voltage at “BLK/RED”, “PNK” and “BLK” wire

terminals of disconnected CKP sensor con-

nector. See fig. 1.

Te r m i n a l “B+”: 10 – 14 V

Te r m i n a l “Vout”: 4 – 5 V

Te r m i n a l “GRD”: 0 V

Is check result satisfactory?

Go to Step 5. Go to Step 4.

4Was terminal “Vout” voltage in Step 3 out of speci-

fication?

“PNK” wire open, short or

poor connection.

If wire and connection are

OK, substitute a known-

good ECM and recheck.

“BLK/RED” and “BLK”

wire open, short or

poor connection.

5 Check Ground Circuit.

1) Turn ignition switch to OFF position.

2) Measure resistance between “BLK” wire termi-

nal of CKP sensor connector and engine

ground.

Is resistance below 5

Ω

?

Go to Step 6. “BLK” wire open or

high resistance.

6 Check Engine Start Signal.

1) Check voltage between “E22-35” wire terminal

of ECM connector and engine ground with

engine cranking.

Does it voltage more than 6 V?

Go to Step 7. “BLK/YEL” wire circuit

open, high resistance

or shorted to ground.

If wire are OK, check

starting motor refer-

ring to “Performance

Test” in Section 6G.

Loading...

Loading...