ENGINE GENERAL INFORMATION AND DIAGNOSIS (M13 ENGINE) 6-2-117

DTC Confirmation Procedure

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Crank engine for 5 sec.

4) Check DTC and pending DTC.

Troubleshooting

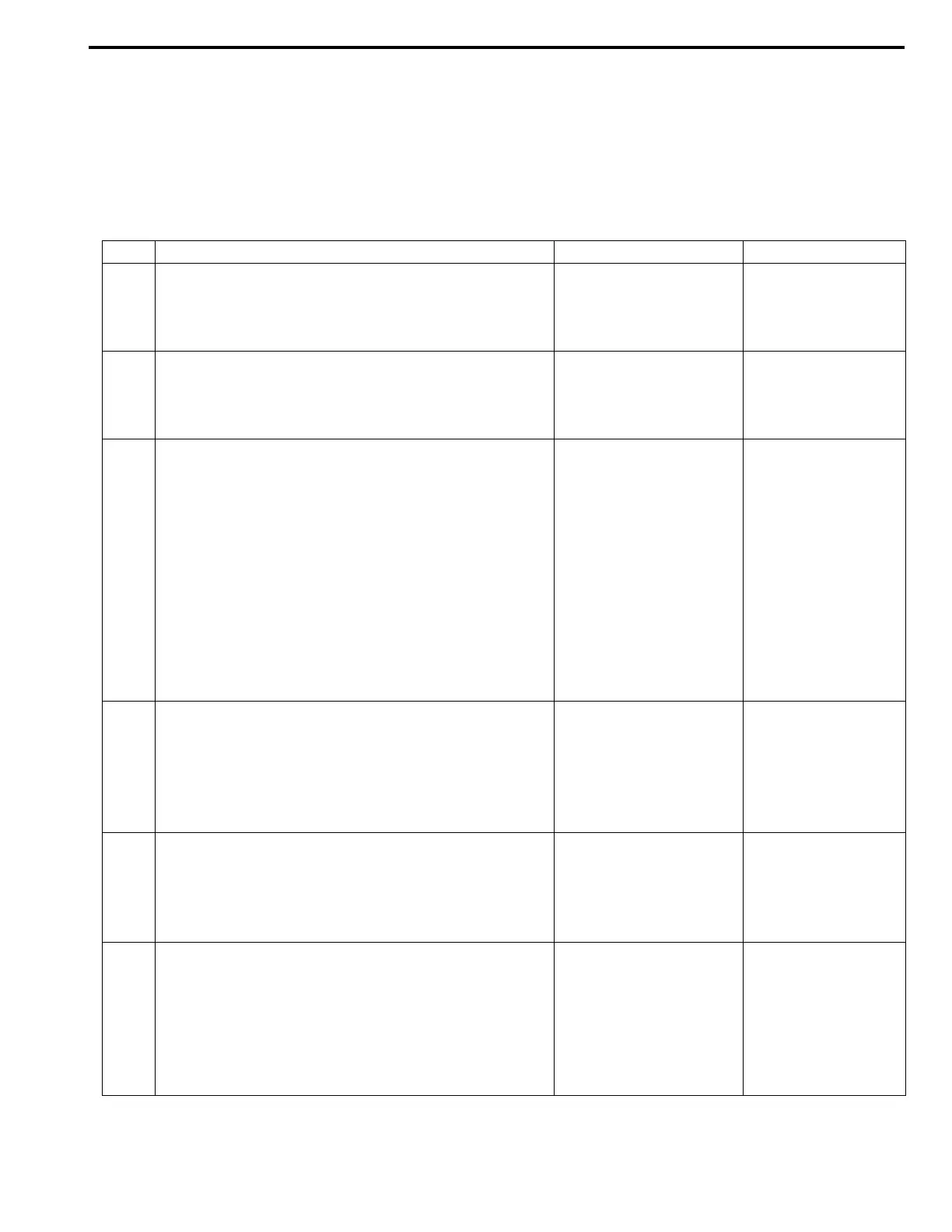

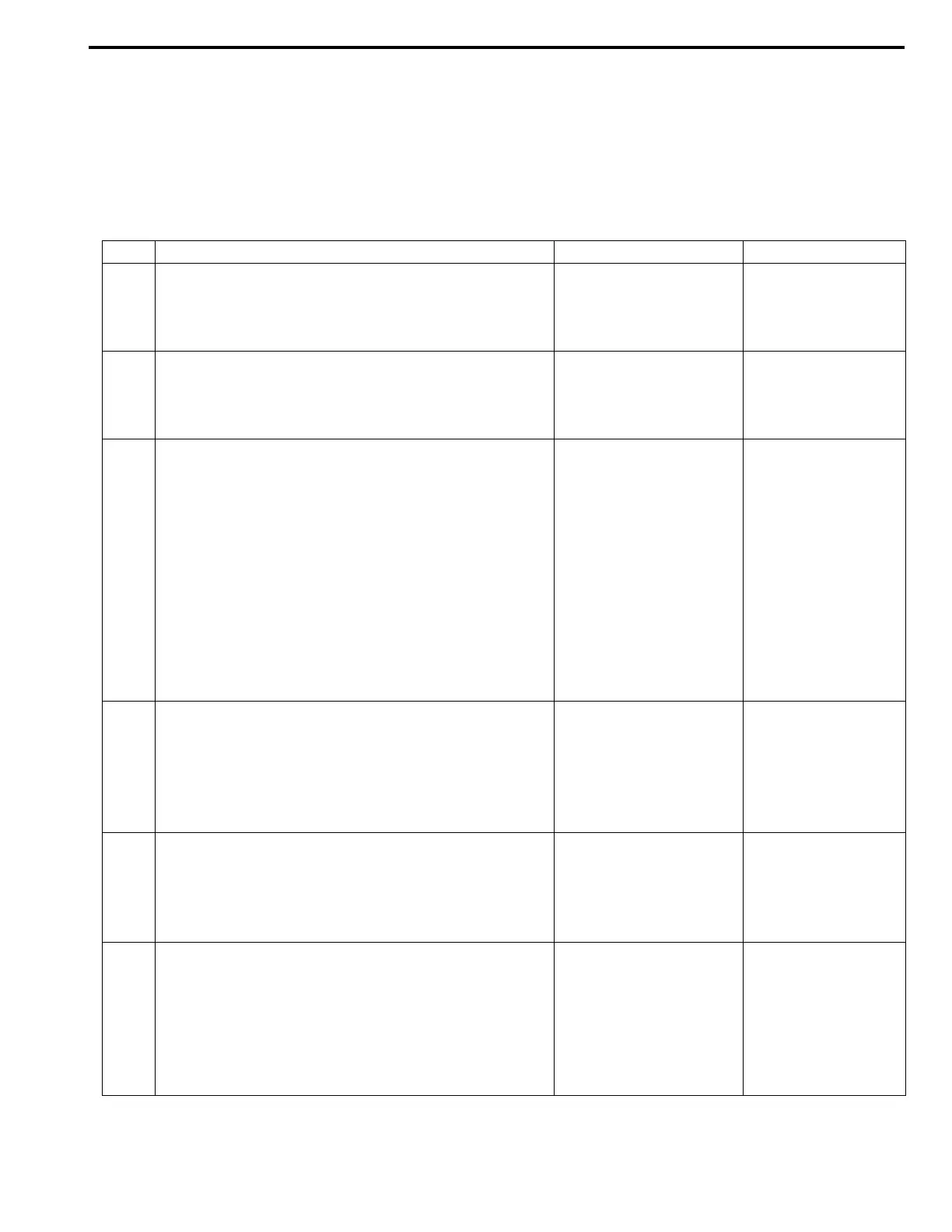

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?

Go to Step 2. Go to “Engine and

Emission Control

System Check” in

this section.

2 Check CMP sensor and connector for proper installa-

tion.

Is CMP sensor installed properly and connector con-

nected securely?

Go to Step 3. Correct.

3 Check Wire Harness and Connection.

1) Disconnect connector from CMP sensor.

2) Check for proper connection to CMP sensor at

“BLK/RED”, “ORN” and “BLK” wire terminals.

3) If OK, turn ignition switch ON and check for volt-

age at “BLK/RED”, “ORN” and “BLK” wire termi-

nals of disconnected CMP sensor connector. See

fig. 1.

Te r mi n al “B+”: 10 – 14 V

Te r mi n al “Vout”: 4 – 5 V

Te r mi n al “GRD”: 0 V

Is check result satisfactory?

Go to Step 5. Go to Step 4.

4 Was terminal “Vout” voltage in Step 3 out of specifica-

tion?

“ORN” wire open, short

or poor connection.

If wire and connection

are OK, substitute a

known-good ECM and

recheck.

“BLK/RED” and

“BLK” wire open,

short or poor con-

nection.

5 Check Ground Circuit.

1) Turn ignition switch to OFF position.

2) Check for continuity between “BLK” wire terminal

of CKP sensor connector and engine ground.

Is continuity indicated?

Go to Step 6. “BLK” wire open or

poor connection.

6 Check Engine Start Signal.

1) Check voltage between “E22-35” wire terminal of

ECM connector and engine ground with engine

cranking.

Does it voltage more than 6 V?

Go to Step 7. “BLK/YEL” wire cir-

cuit open or shorted

to ground.

If wire are OK, check

starting motor refer-

ring to “Performance

Te st” in Section 6G.

Loading...

Loading...