09/2007

3-26

Phaser 8860/8860MFP Service Manual

Initial Issue

Image Quality

Analyzing Service Test Prints

A variety of test prints are available in the Hidden Service Menu to aid in determining the qual-

ity of output from the system and to assist in troubleshooting problems. This section shows how

to select and analyze all test prints available to the system. To access the Test Print menu,

open the Hidden Service Menu from the Control Panel.

NOTE: Defects revealed by the prints may not occur in the course of ordinary printing. In ser-

vicing the system, you should minimize the defects shown by the prints but not necessarily

eliminate them.

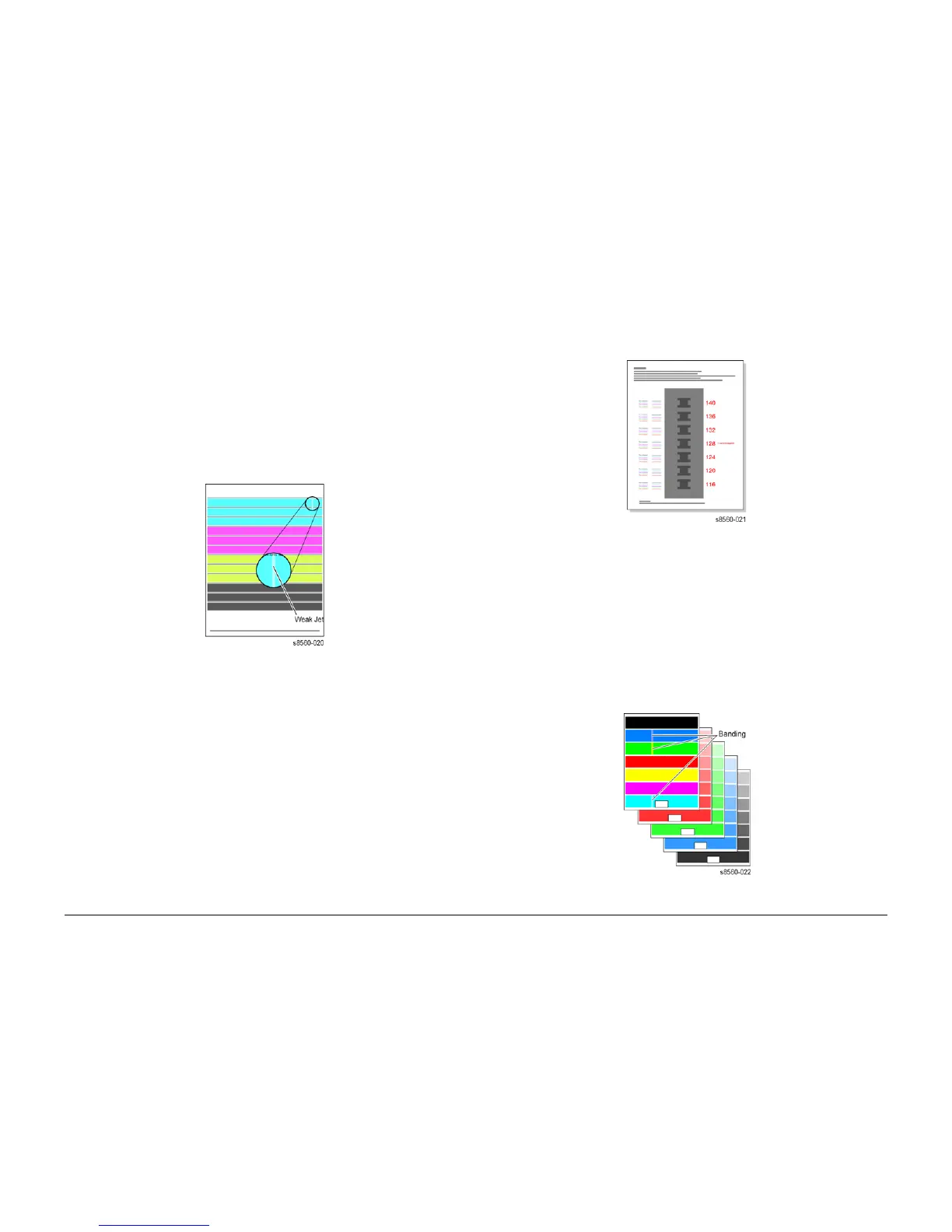

Weak or Missing Jet

This print shows the jets not outputting enough ink, if any, compared to its neighboring jets.

Note that the yellow jets’ bands have a small amount of cyan ink added to them. This tints them

green to make them more visible.

Figure 1 Test Print 1 Weak or Missing Jet

Look for: No interlacing is used in this print: expect light/dark variation between jets. Use Look

for much lighter colored vertical bands in the horizontal bars. Weak jets in the yellow band are

distinguished by a cyan tint.

Causes: A jet may be partially clogged. Perform printhead clean/purge cycles on the printhead

to remove contaminants from the poorly-performing jet. Run a jet fix cycle by downloading the

snippet from the customer support site.

If jet substitution mode is required, see Jet Substitution Mode. Test the purge system and the

wiper blade performance. Turn the system off for 4 to 6 hours (or overnight, if practical). Then

perform a clean/purge cycle again. There may be a problem in the Purge Pump assembly or

the wiper assembly may not be compliant. Verify that the printer is using Xerox ink. Follow the

instructions on the “Printhead Troubleshooting Checklist”.

X-Axis Motion (Drop Mass Evaluation)

For X-Axis Motion problems, see solid fill test prints. This print is used by Engineering and

Manufacturing. The print must be printed on Xerox Photo Paper. Using a lower grade paper

results in inaccurate measurements.

Figure 2 Test Print 2 X-Axis Motion

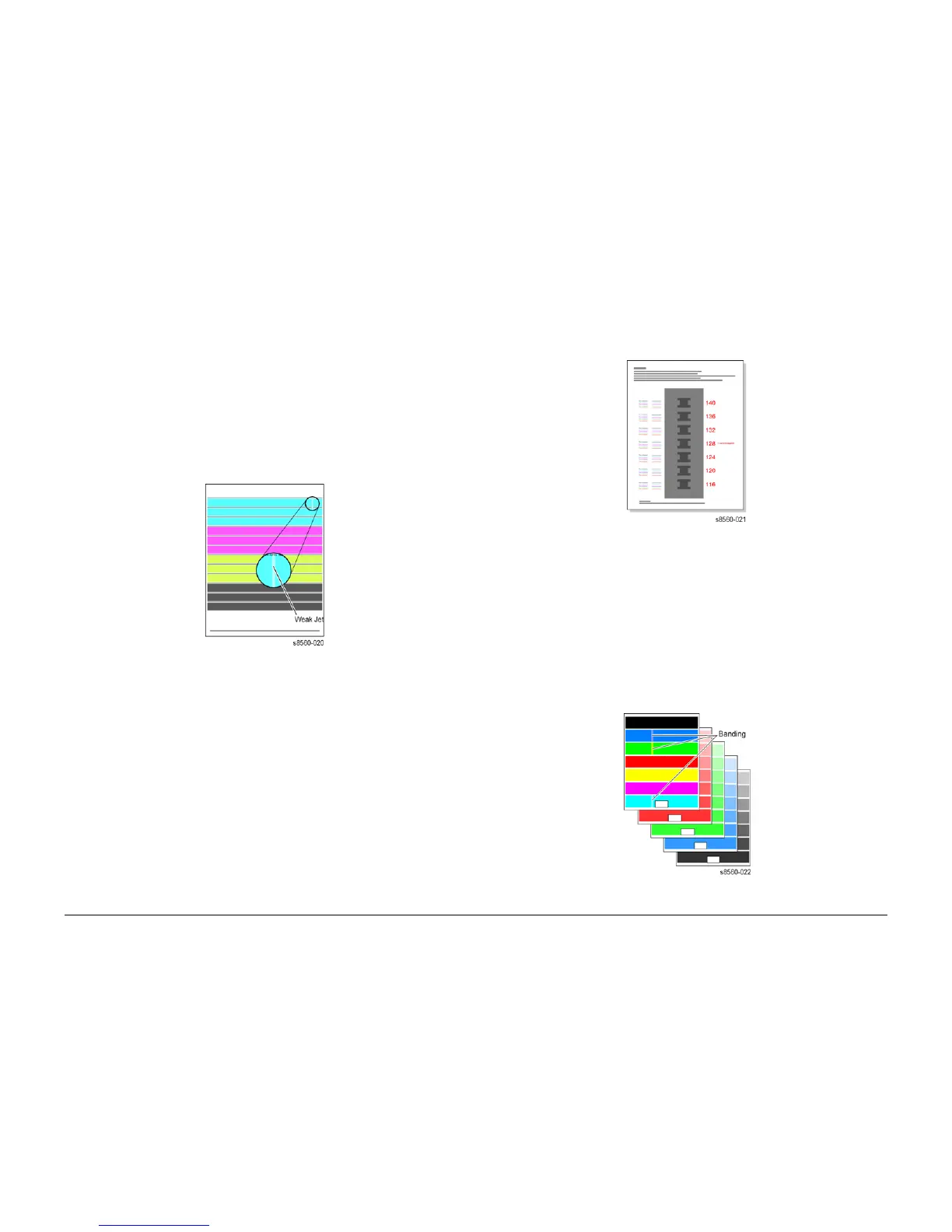

Color Bands, RGBK Dither

The large, secondary colored areas in this print reveal banding and weak jets.

Look for: Vertical “bars” or “bands” of much lighter color or a different hue running in-line in one

or more of the solid fills.

Causes: A weak jet can cause banding; see the Weak/Missing Jets test print. Banding can also

be caused by color-to-color misregistration. Use Service Diagnostics to ensure that the print-

head and drum thermals are correct. Follow the instructions on the “Printhead Troubleshooting

Checklist”.

Figure 3 Test Print 3 Color Bands

Loading...

Loading...