09/2007

2-53

Phaser 8860/8860MFP Service Manual

Jam Codes

Error Messages and Codes

Initial Issue

Jam Codes

The system stores the most recent 20 events in Jam History. To access this information, press

and hold the Up Arrow button, then scroll to Jam History and press OK. Jam codes for Pro-

cess Events differ between models. Tables 1 and 2 list the code keys for each model. Tab le 3

provides troubleshooting information for the most common jams.

NOTE: The following table defines the first 3-digits. The 4th digit represents the tray number

(1~4), 5 represents a chase page, and 6 represents duplex. Numbers following the 4th digit are

the system page count:

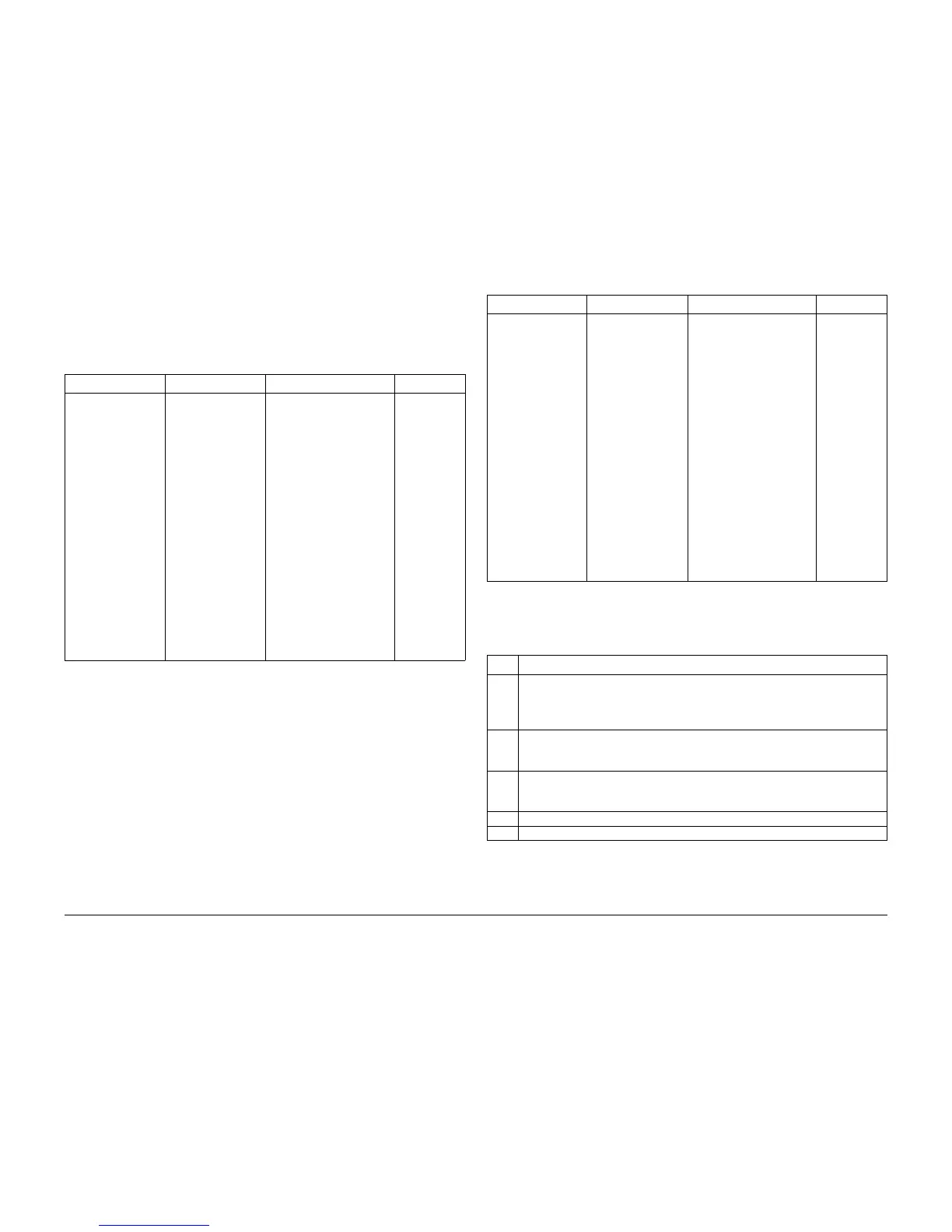

Table 1 8860 Jam Code Key

Process Event Basis for Jam System State Media Supply

A Deskew Flag

B Preheater Flag

C Strip Flag

D Exit Flag

E Tray 1 Width

F Front Door

G Tray 2 Media

H Tray 3 Media

J Tray 4 Media

M Media Drive

N Y-Axis Motor

P Process Drive

T Exit Door

V Tray 2 Event

W Tray 3 Event

X Tray 3 Pick Flag

Y Tray 4 Event

Z Tray 4 Pick Flag

2 Sensor Event

3 Timeout

4 Motor Stall

5 Motor Position

6 Length Short

7 Length Long

A Abnormal shutdown

B Normal shutdown

C Mechanical recovery

D Warmup

E Ready

F Fault

G Auto Drum Maintenance

H Printhead Maintenance

J Printhead purge

K Oil Transfix Roller

L Standby

M Pick from Tray 2

N Pick from Tray 3

P Pick from Tray 4

Q Pick from Tray 1

R Pick from Duplex

S Stage for transfix

T Transfix

V Drum Maintenance

W Imaging

X Exit

Z Shutdown

1 Tray 1

2 Tray 2

3 Tray 3

4 Tray 4

5 Chase Page

6 Duplex

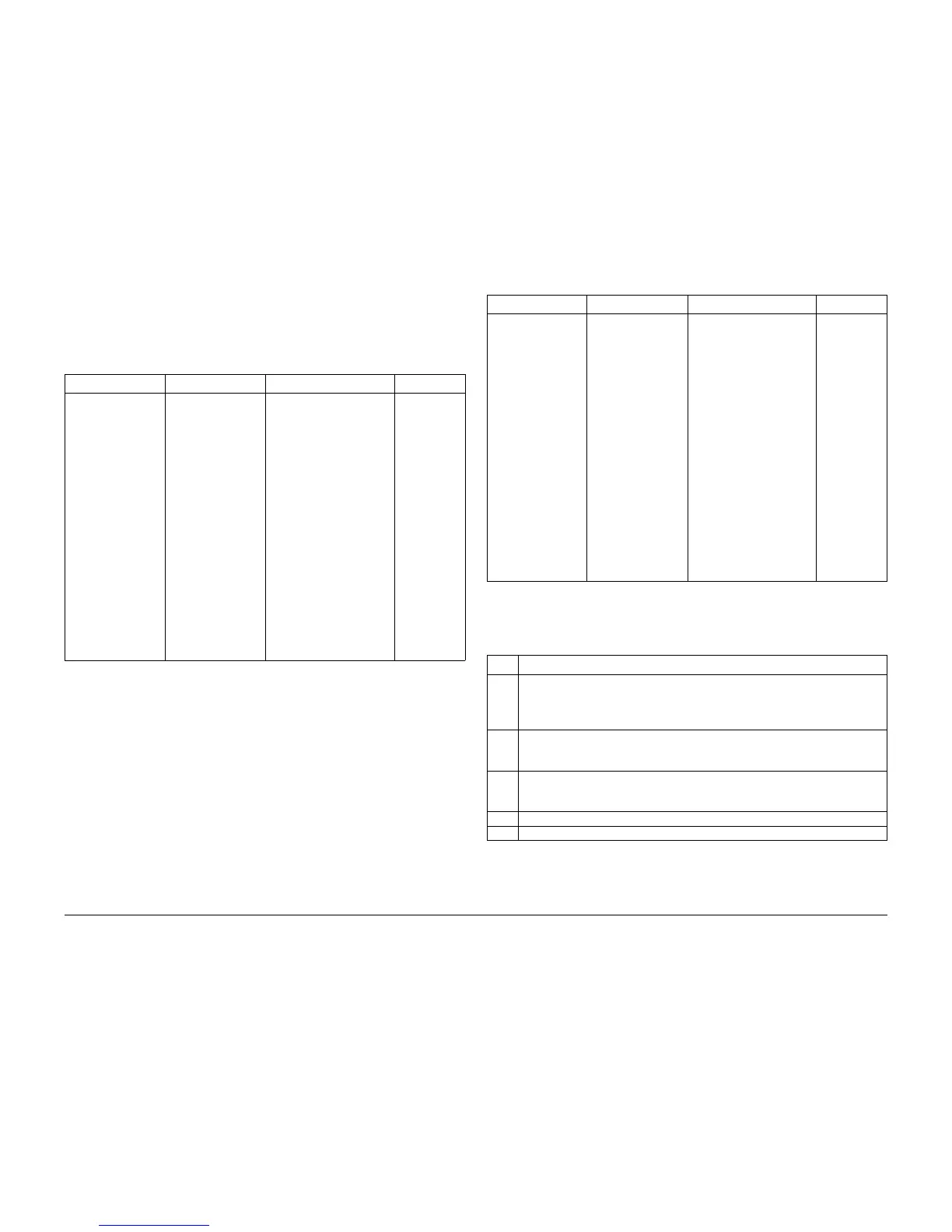

Table 2 8860MFP Jam Code Key

Process Event Basis for Jam System State Media Supply

A Deskew Flag

B Preheater Flag

C Strip Flag

D Exit Flag

E Tray 1 Width

F Front Door

G Exit Door

H Tray 2 Media

J Tray 3 Media

K Tray 4 Media

M Media Drive

N Y-Axis Motor

P Process Drive

V Tray 2 Event

W Tray 3 Event

X Tray 3 Pick Flag

Y Tray 4 Event

Z Tray 4 Pick Flag

2 Sensor Event

3 Timeout

4 Motor Stall

5 Motor Position

6 Length Short

7 Length Long

A Abnormal shutdown

B Normal shutdown

C Mechanical recovery

D Warmup

E Ready

F Fault

G Auto Drum Maintenance

H Printhead Maintenance

J Printhead purge

K Oil Transfix Roller

L Standby

M Pick from Tray 2

N Pick from Tray 3

P Pick from Tray 4

Q Pick from Tray 1

R Pick from Duplex

S Stage for transfix

T Transfix

V Drum Maintenance

W Imaging

X Exit

Z Shutdown

1 Tray 1

2 Tray 2

3 Tray 3

4 Tray 4

5 Chase Page

6 Duplex

Table 3 Jam Code Troubleshooting

Code Description / Procedure

A2C Deskew sensor in unexpected state during mechanical recovery.

1. Check the Drum Maintenance Kit NVRAM contacts during oiling for continuity.

2. Instruct customer to remove media from Tray 1 before opening the front door.

3. Replace the pivot arm.

A2E Deskew sensor in unexpected state at ready.

1. Check system grounding.

2. Replace Tray 1 Pick Solenoid.

A2F Deskew sensor in unexpected state.

1. Check system grounding.

2. Verify all doors and covers are fully closed and not moving during printing.

A2J Deskew flag sensor event during head purge.

A2K Deskew sensor in an unexpected state during a Transfix Roller oiling.

Loading...

Loading...