09/2007

6-16

Phaser 8860/8860MFP Service Manual

Print Engine Check Menu Tests

Initial Issue

Diagnostics

Wiper Shaft Test

This test exercises the Head Maintenance Clutch and Wiper Assembly. The test raises the

wiper to just under the tilt engage point, and then moves the wiper to home position to initialize

the drive mechanism. Next, the Printhead is tilted back out of the way and the Media Drive

Assembly is driven for a short time. While the Media Drive Assembly is being driven, the Head

Maintenance Clutch is engaged. Finally, the clutch is released and the Media Drive Assembly

is stopped. This process repeats for the opposite direction.

If the Printhead does not tilt to the Standby position, the Wiper Blade will interfere with the

Printhead causing error in the recorded values. The system response to the Head Mainte-

nance Clutch activity demonstrates the clutch characteristics. Steady state drive values indi-

cate bearing status and the condition of the pulleys, belts, and shafts. The CW and CCW

measurements are slightly different due to the vertical motion of the Wiper Assembly. The data

used is the Media Drive Assembly servo system following error (fe), which is a measure of how

hard the system is working at any point in time.

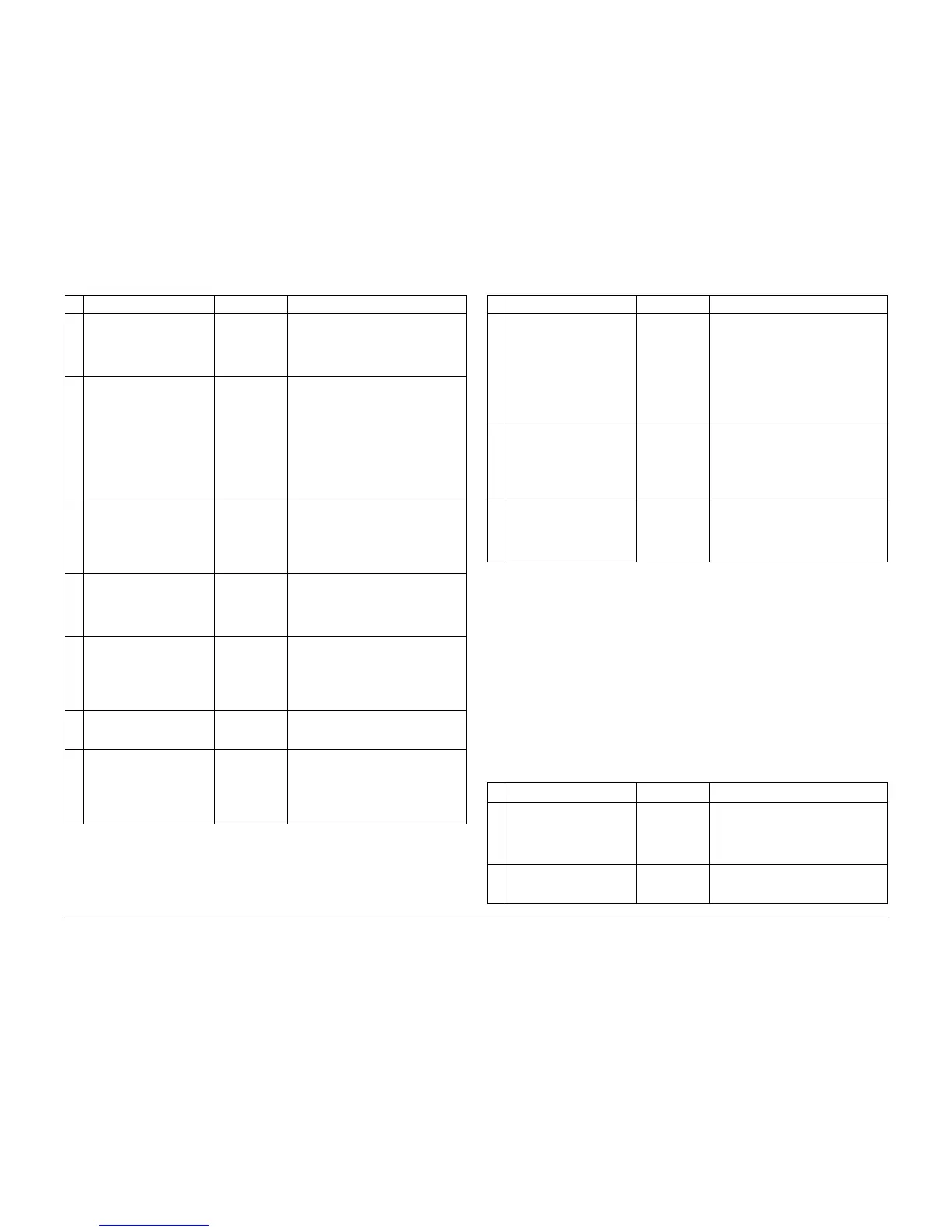

2 CCW On fe settling time (sec) N/A Reports the time it takes the MP motor

servo system to settle down after the

sudden addition of the deskew shaft

load. A longer time could indicate a loose

deskew shaft or a slipping clutch.

3 CCW On average fe N/A Reports the average effort required to

rotate the deskew shaft in the CCW

direction at a constant velocity. An

unusual value could indicate a difference

in the composition and/or number of the

rollers, the nip pressure, or out of range

mechanical dimensions due to wear or

contamination (such as paper dust

increasing the effective diameter of a

roller).

4 CCW On fe ripple N/A Reports the variation of effort required to

rotate the deskew shaft in the CCW

direction at a constant velocity. A larger

value could indicate particles in the

gears or non uniform contamination of a

roller (causing a lump).

5 CCW Off fe settling time (sec) N/A Reports the time it takes the Media Drive

Motor servo system to settle down after

the sudden release of the deskew shaft

load. A larger value can indicate a slow

to release or dragging clutch.

6 Time to CW On peak fe (sec) N/A Reports a time that indicates how long it

takes the MP motor servo system to

react to the sudden addition of the

deskew shaft load. Larger values may

indicate a slipping or slow to engage

clutch.

7 CW On peak fe N/A Reports the peak effort required to accel-

erate the deskew shaft load. A smaller

value could indicate a slipping clutch.

8 CW On fe settling time (sec) N/A Reports the time it takes the MP motor

servo system to settle down after the

sudden addition of the deskew shaft

load. A longer time could indicate a

looseness in the deskew shaft assembly

or a slipping clutch.

Table 10 Deskew Shaft Nominal Values

R# Characteristic Typical Value Result

9 CW On average fe N/A Reports the average effort required to

rotate the deskew shaft in the CW direc-

tion at a constant velocity. An unusual

value could indicate a difference in the

composition and/or number of rollers, the

nip pressure, or out of range mechanical

dimensions due to wear or contamina-

tion (such as paper dust increasing the

effective diameter of a roller).

10 CW On fe ripple N/A Reports the variation of effort required to

rotate the deskew shaft in the CW direc-

tion at a constant velocity. A larger value

could indicate particles in the gears or

non uniform contamination of a roller

(causing a lump).

11 CW Off fe settling time (sec) N/A Reports the time it takes the MP motor

servo system to settle down after the

sudden release of the deskew shaft load.

A larger value could indicate a dragging

or slow to release clutch.

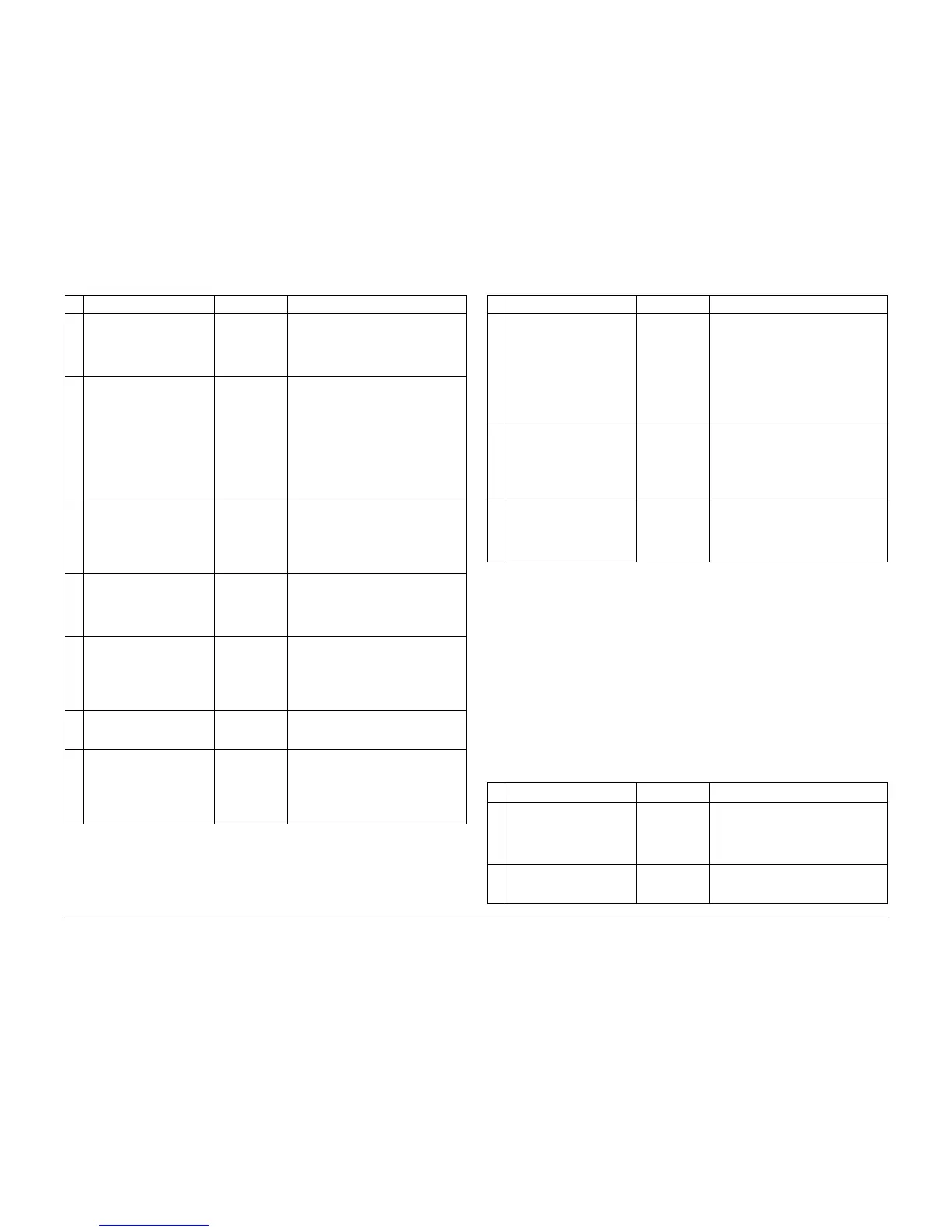

Table 11 Wiper Shaft Nominal Values

R# Characteristic Typical Value Result

0 Time to CCW On peak fe

(sec)

N/A Reports how long it takes the Media

Drive Assembly servo system to react to

the sudden addition of the wiper shaft

load. Larger values may show a slipping/

slow to engage clutch.

1 CCW On peak fe N/A Reports peak effort needed to accelerate

the wiper shaft load. A smaller value

could indicate a slipping clutch.

Table 10 Deskew Shaft Nominal Values

R# Characteristic Typical Value Result

Loading...

Loading...