Three Levels of Protection

WARNING: The control program must not be the only form

of protection for any problems that may result in a risk of

personal injury or equipment damage.

The publications mentioned provide many ideas and

requirements for system safety. At a minimum, you

should follow these regulations. Also, you should use the

following techniques, which provide three levels of system

control.

1. Orderly system shutdown sequence

in the PLC control program

2. Mechanical disconnect for output module power

3. Emergency stop

switch for disconnecting system power

•

Orderly System Shutdown

The first level of fault detection is ideally the PLC control program, which can identify machine

problems. These types of problems are usually things such as jammed parts, etc., that do not

pose a risk of personal injury or equipment damage. However, respective shutdown sequences

should be performed.

System Power Disconnect

You should also use electromechanical devices, such as master control relays and/or limit

switches, to prevent accidental equipment startup at an unexpected time. These devices should

be installed in a manner that will prevent any machine operations from occurring.

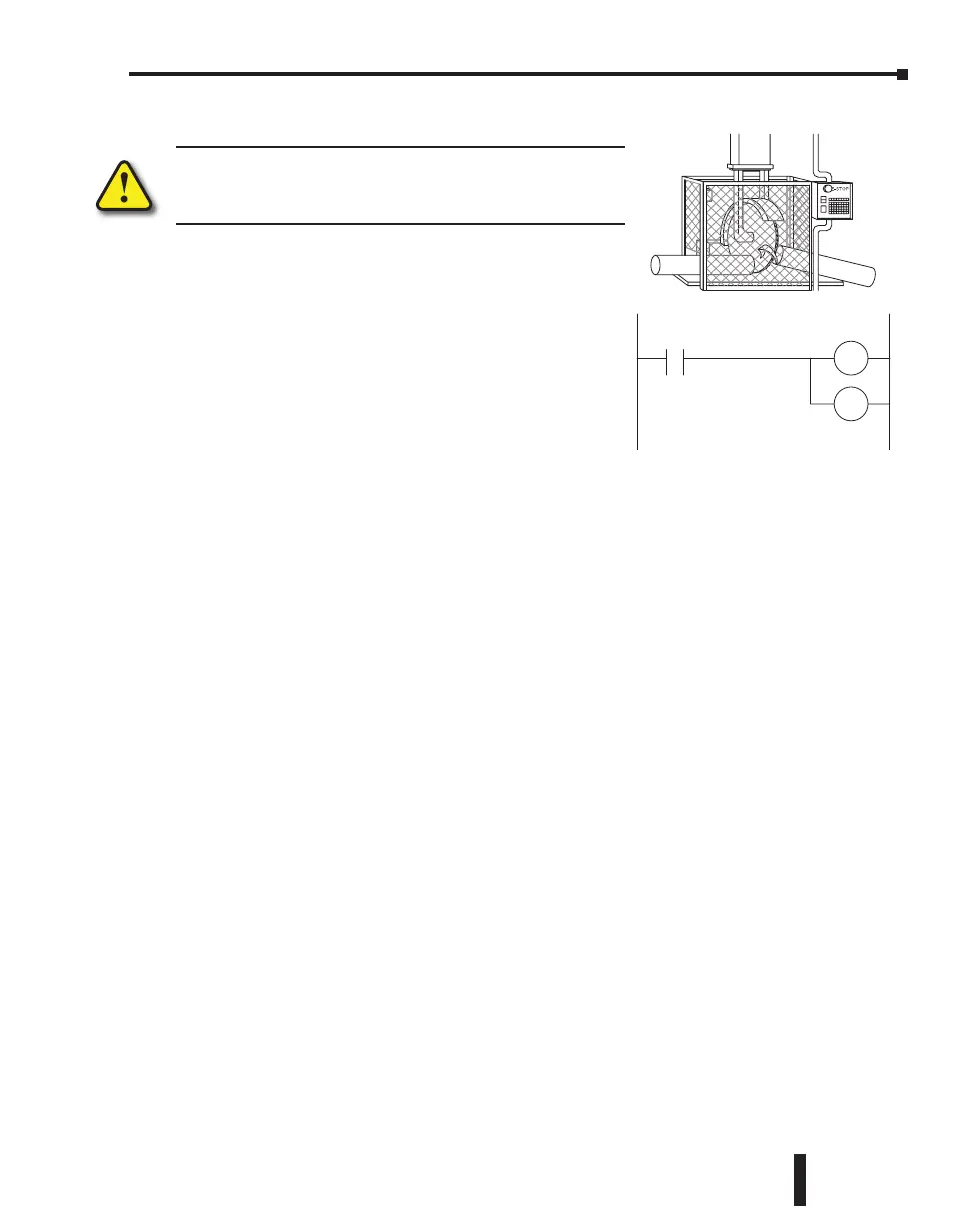

For example, if the machine in the illustration has a jammed part, the PLC control program

can turn off the saw blade and retract the arbor. If the operator must open the guard to remove

the part, you should also include a bypass switch that disconnects all system power any time

the guard is opened.

Jam

Detect

RST

Retract

Turn off

Saw

RST

CLICK PLC Hardware User Manual, 5th Edition, Rev. F – C0-USER-M

3–3

Chapter 3: Installation and Wiring

Loading...

Loading...