Enclosures

Your selection of a proper enclosure is important to ensure safe and proper operation of

your CLICK PLC system. Control applications vary and yours may require additional

considerations. At a minimum your enclosure should include:

• Conformance to electrical standards

• Protection from the elements in an industrial environment

• Common ground reference

• Maintenance of specified ambient temperature

• Access to equipment

• Security or restricted access

• Sufficient space for proper installation and maintenance of equipment

Panel Layout and Clearances

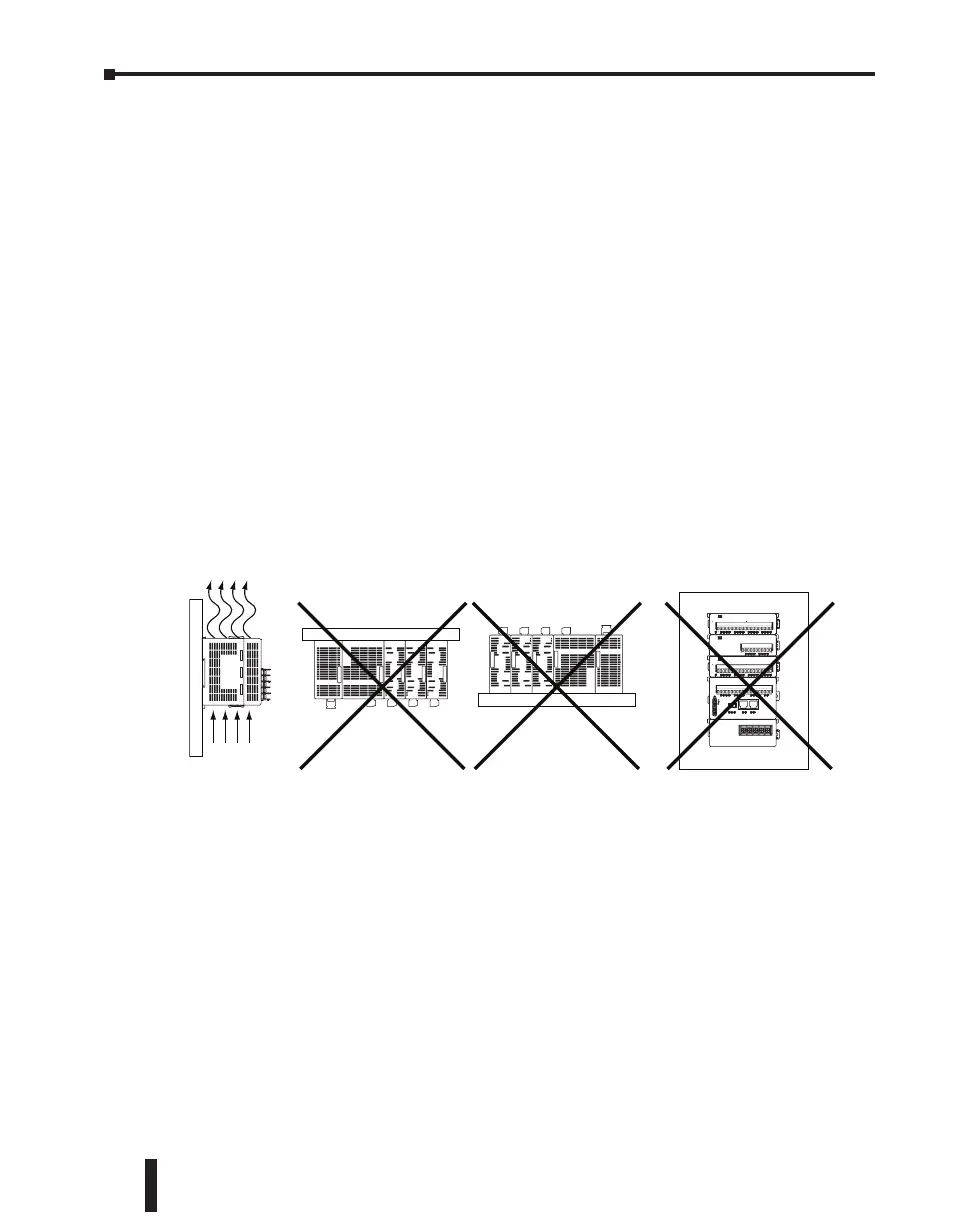

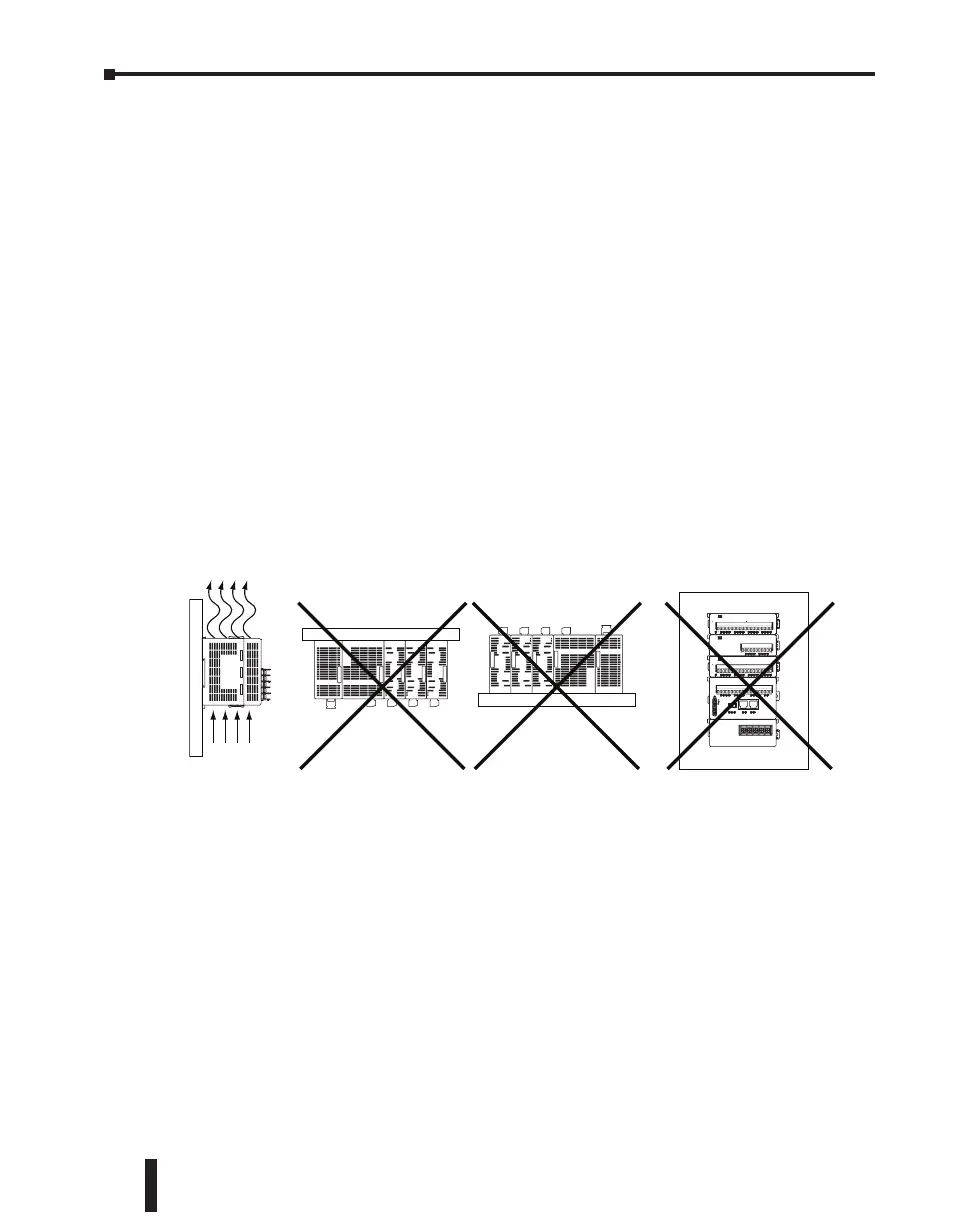

1. Mount the CLICK PLC unit (system) horizontally as shown below to provide proper

ventilation. Do not mount the CLICK PLC units upside down, on a horizontal surface

or in a vertical arrangement. If you place more than one unit in a cabinet, there must be a

minimum of 7.2” (183mm) between the units.

2. Provide a minimum clearance of 2” (50mm) between the unit and all sides of the cabinet.

NOTE: Remember to allow clearance for any operator panels or other items mounted

directly in front of the unit in the door.

3. There should also be at least 3” (78mm) of clearance between the unit and any wiring ducts

that run parallel to the terminals.

4. The ground terminal on the CLICK PLC must be connected to a single point ground. Use

copper stranded wire to achieve a low impedance. Copper eye lugs should be crimped and

soldered to the ends of the stranded wire to ensure good surface contact.

5. There must be a single point ground (i.e. copper bus bar) for all devices in the panel

requiring an earth ground return. The single point of ground must be connected to the

panel ground termination. The panel ground termination must be connected to ground.

Minimum wire sizes, color coding, and general safety practices should comply with

appropriate electrical codes and standards for your area.

Air

TX2

PORT2

PORT1

RX2

RX1

TX1

PWR

ERR

RUN

STOP

RUN

CLICK PLC Hardware User Manual, 5th Edition, Rev. F – C0-USER-M

3–14

Chapter 3: Installation and Wiring

Loading...

Loading...