6. A good common ground reference (Earth ground) is essential for proper operation of the

CLICK PLC. One side of all control and power circuits and the ground lead on flexible

shielded cable must be properly connected to Earth ground. There are several methods of

providing an adequate common ground reference, including:

a) Installing a ground rod as close to the panel as possible

b) Connection to incoming power system ground

7. Evaluate any installations where the ambient temperature may approach the lower or

upper limits of the specifications. If you suspect the ambient temperature will not be

within the operating specification for the CLICK PLC system, measures such as installing

a cooling/heating source must be taken to get the ambient temperature within the range of

specifications.

8. CLICK PLC systems are modular and can be powered by any suitable 24VDC power

supply. The optional CLICK power supply is designed to attach to the left side of the

CLICK PLC case. CLICK power supplies accept 85-264 VAC and produce nominal

24VDC to power the CLICK PLC and I/O modules. Powerline filters are recommended for

protecting the CLICK PLC from power surges and EMI/RFI noise. The AutomationDirect

Powerline Filter, for use with 120VAC and 240VAC, 1–5 Amps, is an excellent choice

(locate at www.automationdirect.com), however, you can use a filter of your choice. The

filter units install easily between the AC power source and the PLC.

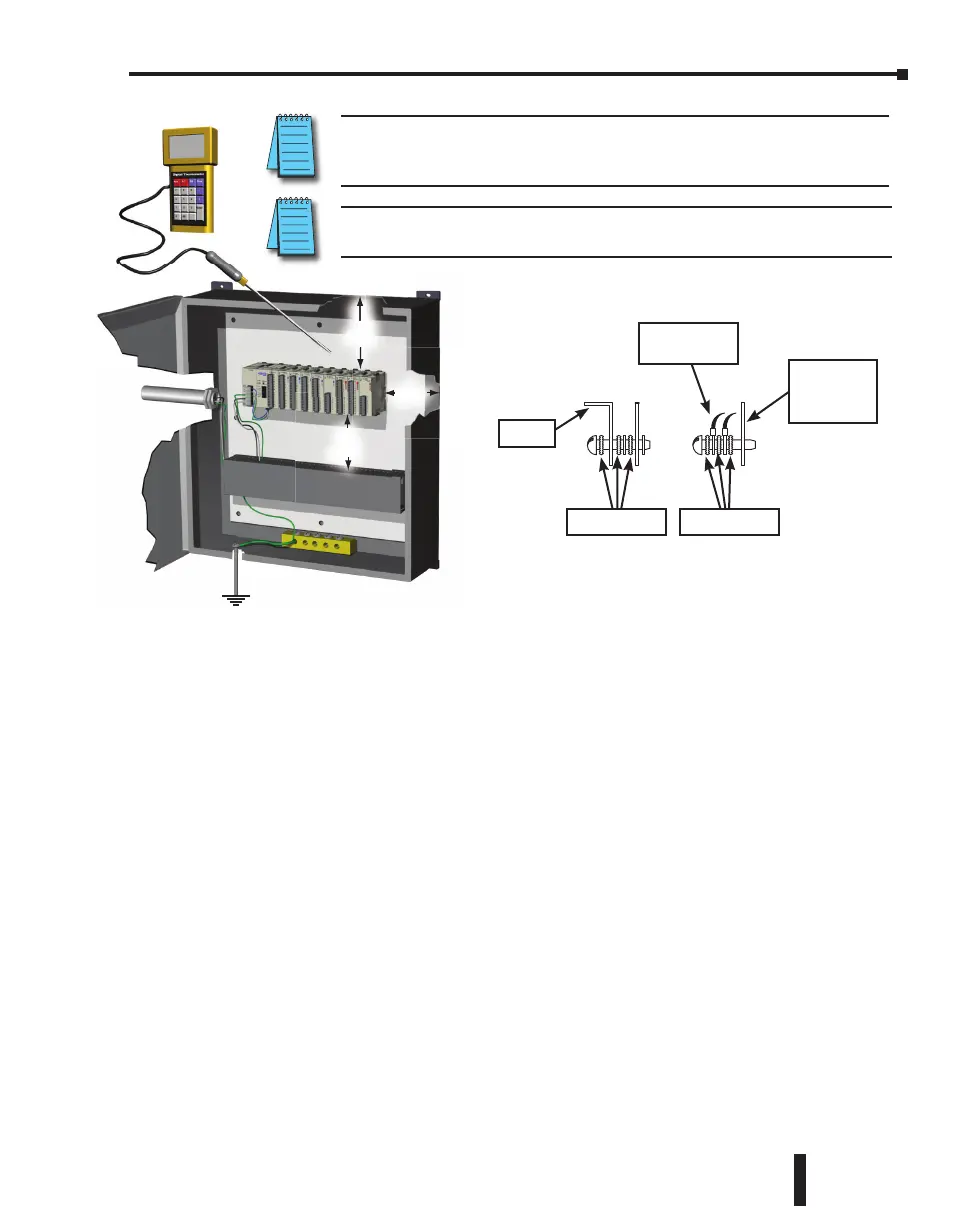

2 in.

50.8 mm

minimum

3 in.

76.2 mm

minimum

2 in.

50.8 mm

minimum

i

.

m

n

NOTE: There is a minimum clearance requirement of 2” (51mm) between the

CLICK PLC and the panel door or any devices mounted in the panel door. The

same clearance is required between the PLC and surrounding enclosure.

NOTE: A minimum clearance of 3” (76mm) is required between the PLC and a

wireway or any heat producing device.

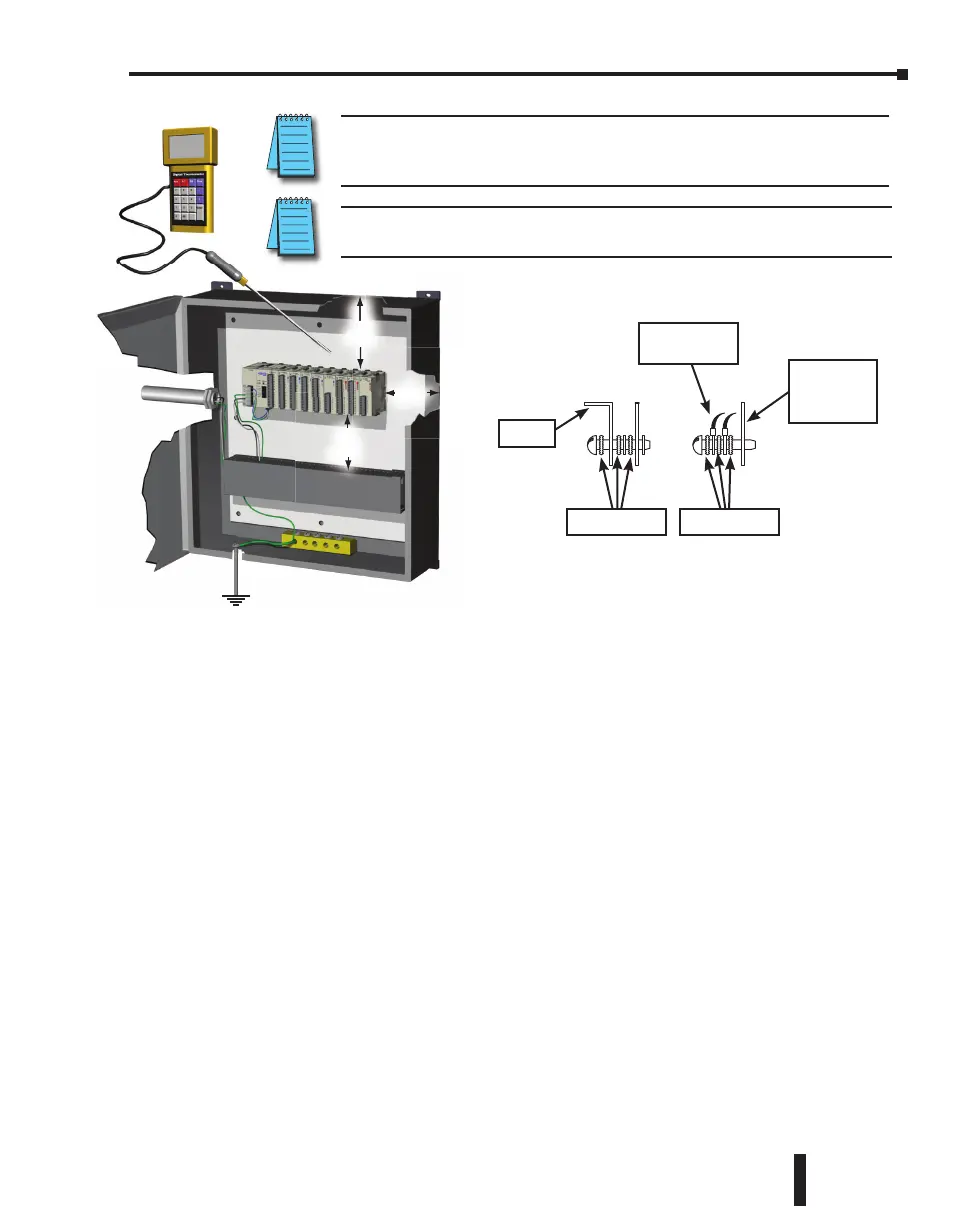

Panel or

Single Point

Ground

Ground Braid

Copper Lugs

Star Washers

Star Washers

Panel

CLICK PLC Hardware User Manual, 5th Edition, Rev. F – C0-USER-M

3–15

Chapter 3: Installation and Wiring

Loading...

Loading...