System Wiring Strategies

The CLICK PLC system is very flexible and will work in many different wiring configurations.

By studying this section before actual installation, you can find the best wiring strategy for your

application. This will help to lower system cost and wiring errors, and avoid safety problems.

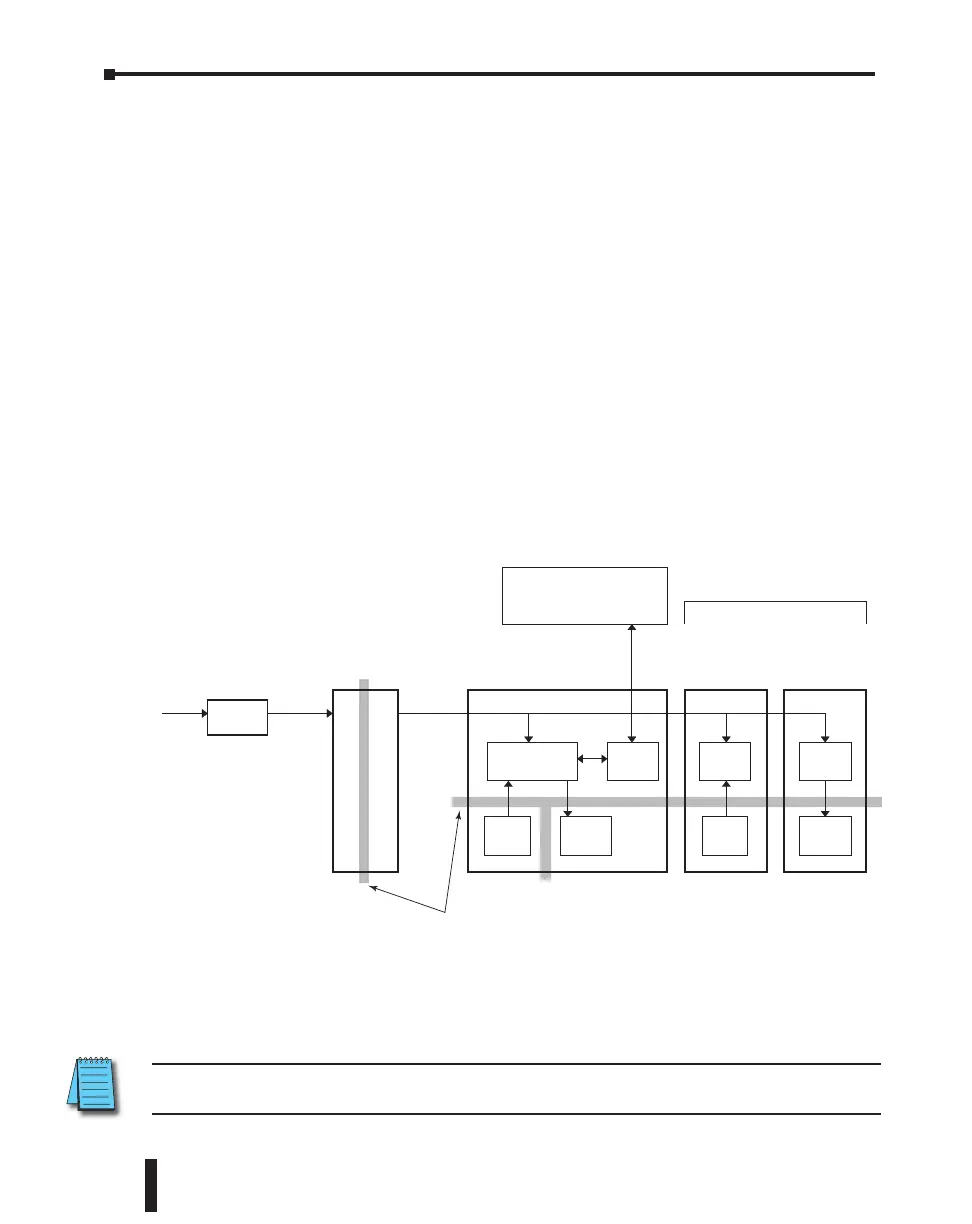

PLC Isolation Boundaries

PLC circuitry is divided into three main regions separated by isolation boundaries, shown

in the drawing below. Electrical isolation provides safety, so that a fault in one area does

not damage an adjacent area. A powerline filter will provide isolation between the power

source and the power supply. The transformer in the power supply provides magnetic isolation

between the primary and secondary sides. Optical isolators provide optical isolation in Input

and Output circuits. These methods isolate logic circuitry from the field side, where factory

machinery connects. The discrete inputs are isolated from the discrete outputs, because each is

isolated from the logic side. Isolation boundaries protect the devices such PC and HMI that are

connected to the communication ports, from power input faults or field wiring faults. When

wiring a PLC, it is extremely important to avoid making external connections that connect

logic side circuits to more than one circuit.

PLC Unit

Power Supply

Power

Input

24VDC

PC, HMI, or other

communication devices

Output ModuleInput Module

Isolation Boundary

Logic Circuit

Com

Ports

Input

Circuit

Output

Circuit

Input

Circuit

Output

Circuit

Logic

Circuit

Logic

Circuit

Filter

Maximum 8 I/O Modules

NOTE: If you do not use one of the CLICK PLC power supplies C0-00AC and C0-01AC to provide 24VDC

to the PLC module (and I/O modules), be sure the power supply you use has isolation with a transformer.

CLICK PLC Hardware User Manual, 5th Edition, Rev. F – C0-USER-M

3–26

Chapter 3: Installation and Wiring

Loading...

Loading...