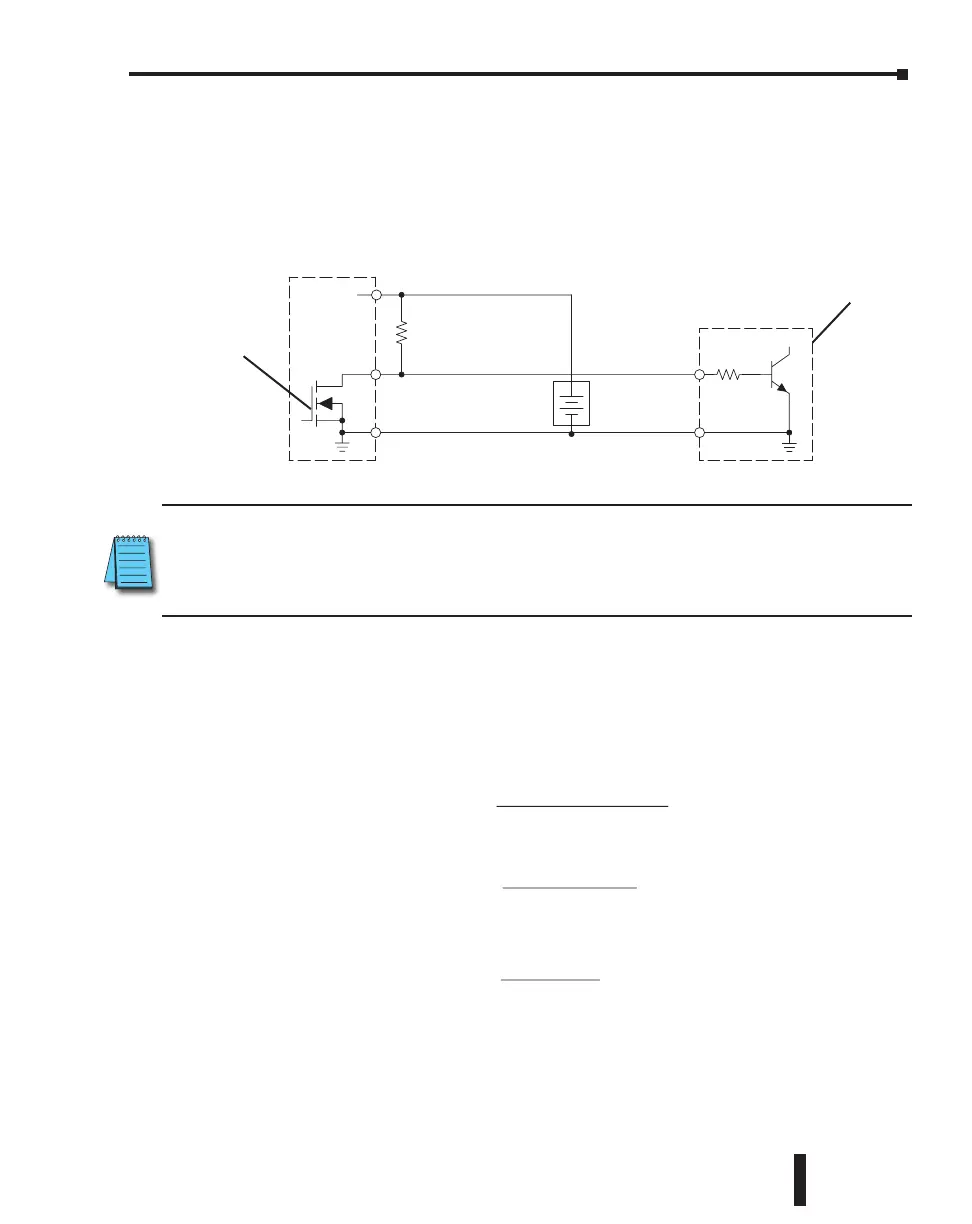

PLC DC Sinking Output to Sinking Load Device

In the example below, a PLC sinking output point is connected to the sinking input of a field

device load. In this case, both the PLC output and field device input are sinking type. Since

the circuit must have one sourcing and one sinking device, we add sourcing capability to the

PLC output by using a pull-up resistor. In the circuit below, we connect Rpull-up from the

output to the DC output circuit power input.

NOTE 1: DO NOT attempt to drive a heavy load (>25 mA) with this pull-up method.

NOTE 2: Using the pull-up resistor to implement a sourcing output has the effect of inverting the output

point logic. In other words, the field device input is energized when the PLC output is OFF, from a ladder

logic point-of-view. Your ladder program must comprehend this and generate an inverted output. Or, you

may choose to cancel the effect of the inversion elsewhere, such as in the field device.

It is important to choose the correct value of R

pull-up

. In order to do so, we need to know the

nominal input current to the field device (I

input

) when the input is energized. If this value is

not known, it can be calculated as shown (a typical value is 15 mA). Then use I

input

and the

voltage of the external supply to compute R

pull-up

. Then calculate the power P

pull-up

(in watts),

in order to size R

pull-up

properly.

Field Device

Output

Ground

Input

Common

PLC DC Output

+DC pwr

+

–

(sourcing)

(sinking)

Power

(sinking)

pull-up

Supply

R

input

R

PLC Output

(Sinking with

Pull-up Resistor)

DC NPN Load

(Sinking)

pull-up

R

input

R

=

supply

V

– 0.7

–

input

I

input

I

=

input (turn–on)

input

R

pull-up

P

=

supply

V

2

CLICK PLC Hardware User Manual, 5th Edition, Rev. F – C0-USER-M

3–31

Chapter 3: Installation and Wiring

Loading...

Loading...