13-18 BE1-951 Testing and Maintenance 9328900990 Rev L

Instantaneous Overcurrent (50T)

50TP/150TP and TN (Calculated 3Io) Pickup and Dropout Verification

Purpose: To verify the accuracy of the operation of the 50TP/150TP and TN (3Io) elements.

Reference Commands: SL-50T/150T, SL-GROUP, SL-VO

Step 1: Connect a current source to Terminals D1 and D2 (A-phase). Refer to

Figure 13-1 for terminal

locations. An ohmmeter or continuity tester may be used to monitor output contact status.

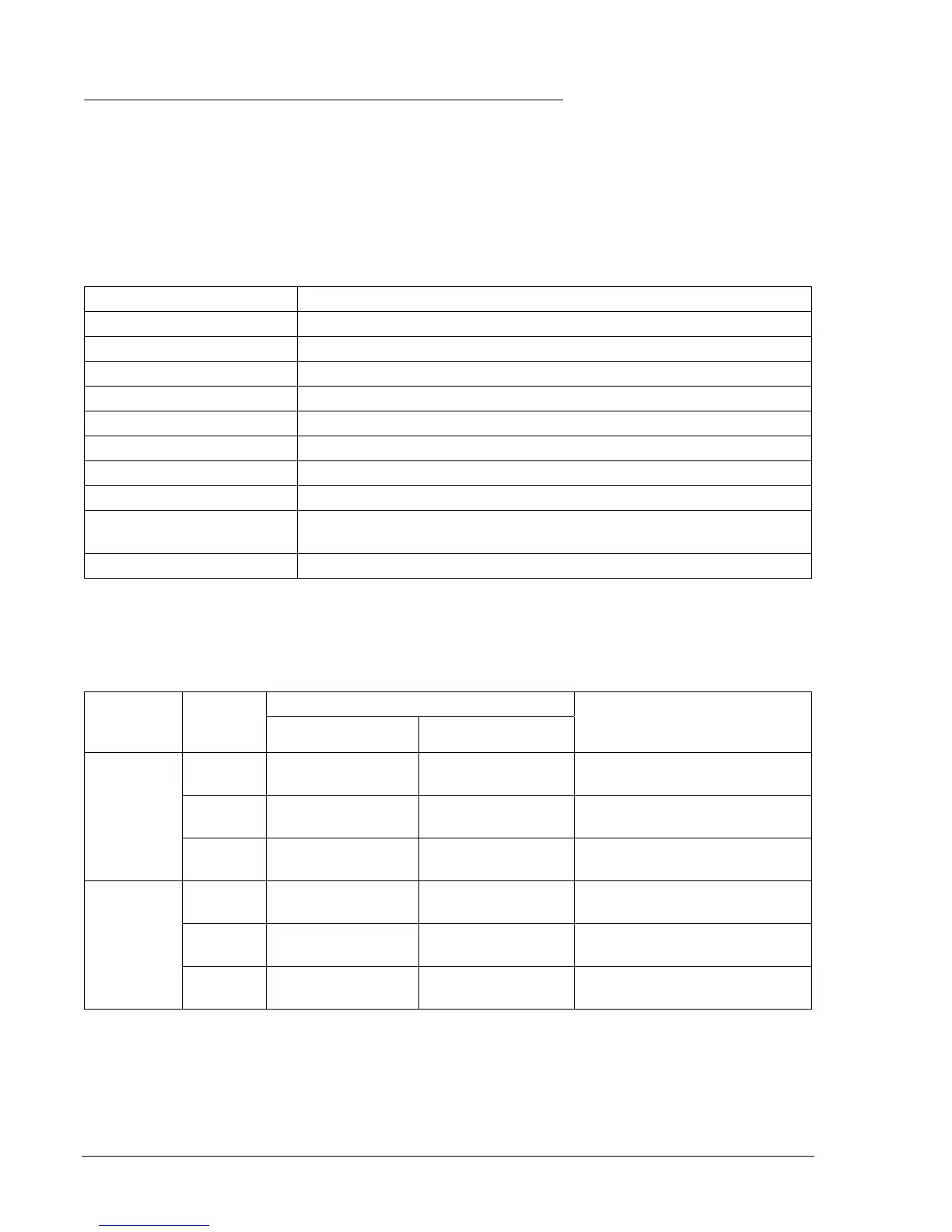

Step 2: Prepare the 50T/150T elements for testing by transmitting the commands in

Table 13-6 to the

relay. Reset targets.

Table 13-6. 50T Pickup Test Commands

Command Purpose

A= Gains write access.

SL-N=NONE Zero out custom logic settings. Overwrite with logic=none settings.

Y Confirm overwrite.

SL-N=PU50 Sets PU50 as custom logic name.

SL-50T=1,0 Enables 50TP, 50TN (3Io), and 50TQ and disables blocking.

SL-VO1=50TPT Enables OUT1 to close for 50TP trip.

SL-VO2=50TNT Enables OUT2 to close for 50TN trip.

SG-CT=1 Sets P, N CT ratio at 1:1

SG- TRIG=50TPT+50TNT,

50TPPU+50TNPU,0

Enable 50TPT or 50TNT to log and trigger fault recording.

EXIT;Y Exit and save settings.

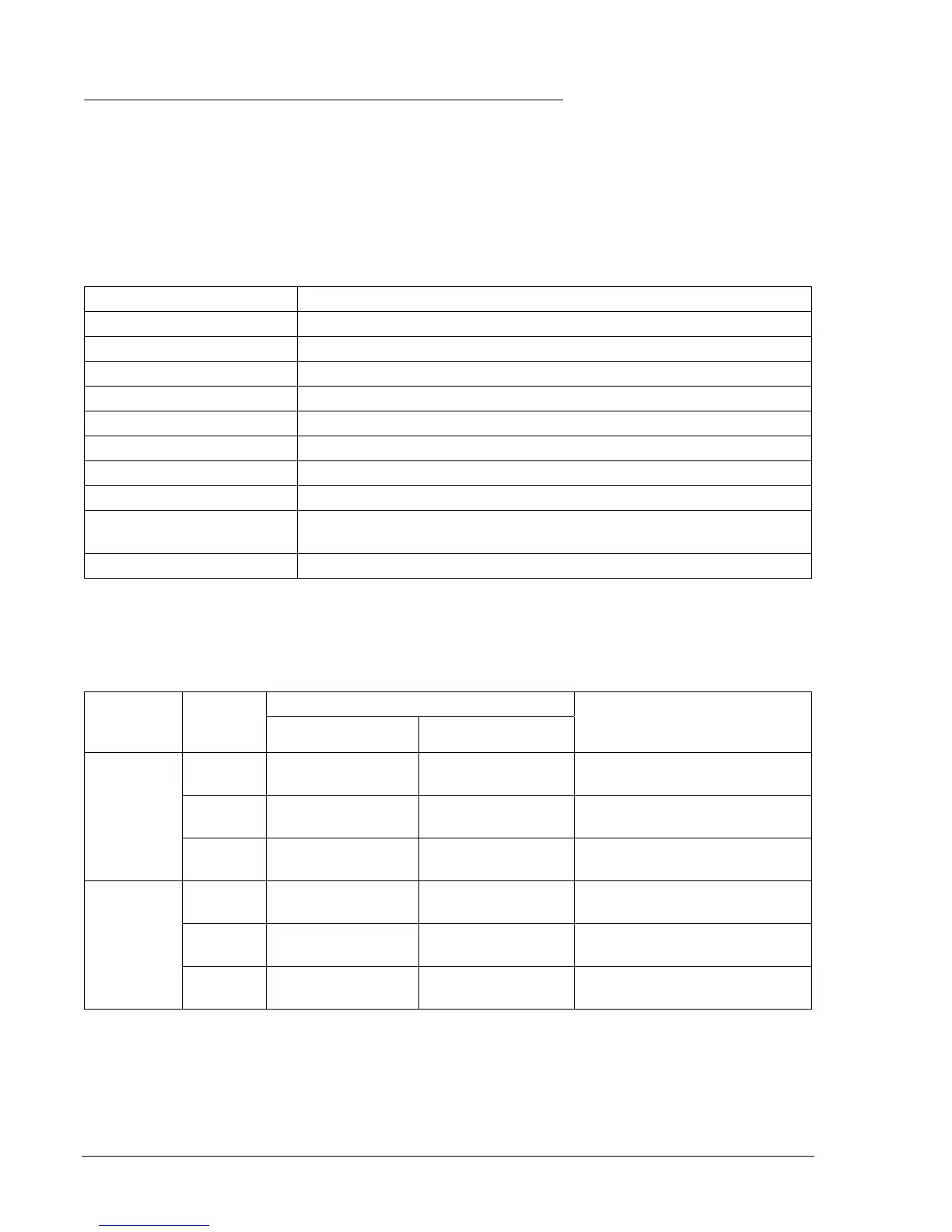

Step 3: Using

Table 13-7 as a guide, transmit the low range setting commands (minimum pickup

setting) for your sensing input type.

Table 13-7. 50T Pickup Settings

Pickup Settings Commands

Current

Sensing

Input Type

Ranges

Phase Neutral

Purpose

Low S0-50TP=0.5,0,N S0-50TN=0.5,0,N

Sets 50T PU at 0.5 A, TD = 0,

non-directional.

Middle S0-50TP=5.0,0,N S0-50TN=5.0,0,N

Sets 50T PU at 5.0 A, TD = 0,

non-directional.

5 A

High S0-50TP=25.0,0,N S0-50TN=25.0,0,N

Sets 50T PU at 25.0 A, TD = 0,

non-directional.

Low S0-50TP=0.1,0,N S0-50TN=0.1,0,N

Sets 50T PU at 0.1 A, TD = 0,

non-directional.

Middle S0-50TP=1.0,0,N S0-50TN=1.0,0,N

Sets 50T PU at 1.0 A, TD = 0,

non-directional.

1 A

High S0-50TP=5.0,0,N S0-50TN=5.0,0,N

Sets 50T PU at 5.0 A, TD = 0,

non-directional.

Step 4: Slowly increase the A-phase current until OUT1 closes. Verify that pickup occurs within the

specified accuracy listed in

Table 13-8. Slowly decrease the applied current until OUT1 opens.

Dropout should occur at 93 to 97 percent of pickup.

Step 5: Repeat Step 4 while monitoring OUT2 (50TN enabled for 3Io). Verify 50TA and 50TN targets on

the HMI.

Step 6: Repeat Steps 4 and 5 for the middle and high range pickup settings for your sensing input type.

Loading...

Loading...