3-6 BE1-951 Input and Output Functions 9328900990 Rev L

Energizing levels for the contact sensing inputs are jumper selectable for a minimum of approximately 5

Vdc for 24 Vdc nominal sensing voltages, 26 Vdc for 48 Vdc nominal sensing voltages, or 69 Vdc for 125

Vdc nominal sensing voltages. See Table 3-2 for the control voltage ranges.

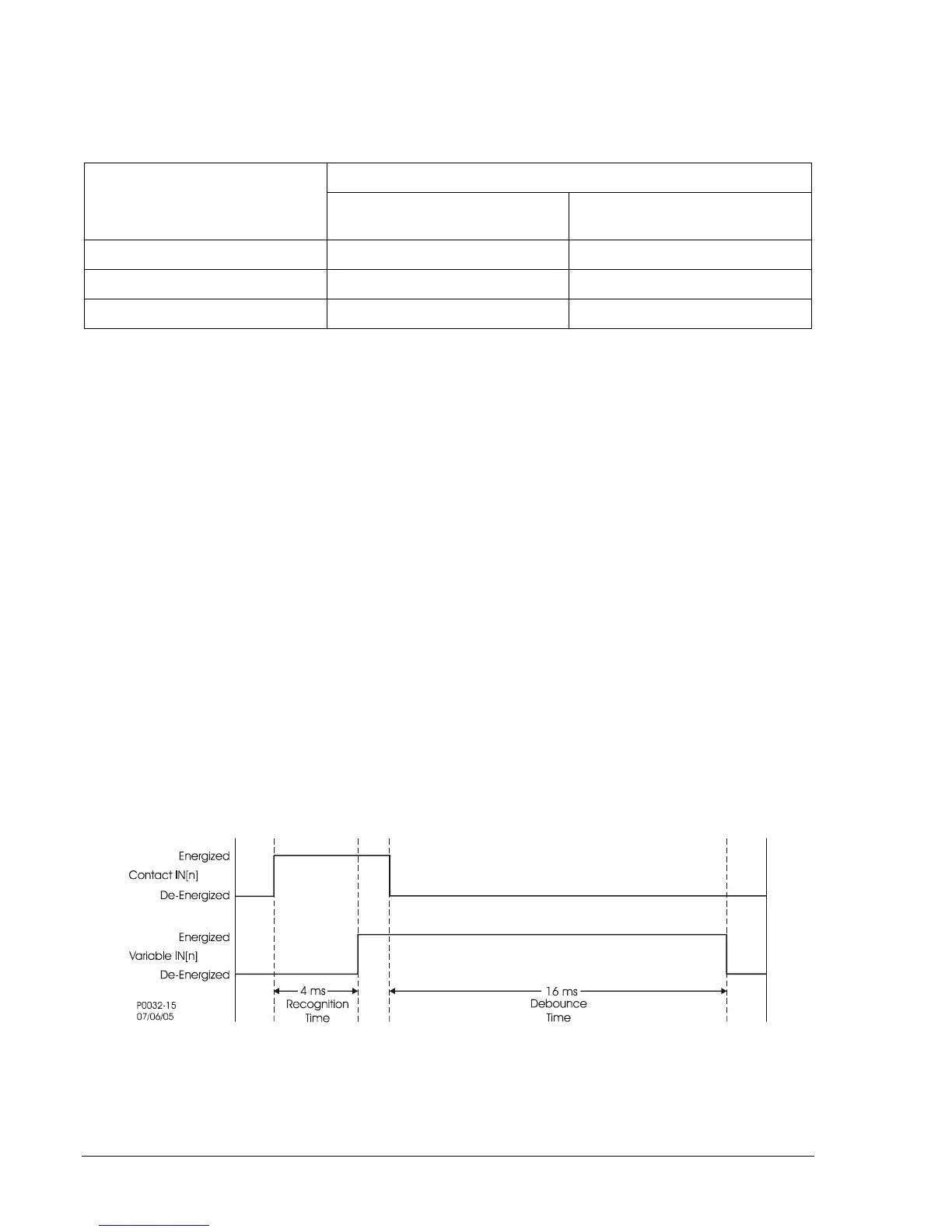

Table 3-2. Contact Sensing Turn-On Voltage

Turn-On Voltage Range

Nominal Control Voltage

Jumper Installed

(Low Position)

Jumper Not Installed

(High Position)

24 Vdc N/A Approx. 5 Vdc

48/125 Vac or Vdc 26 – 38 Vac or Vdc 69 – 100 Vac or Vdc

125/250 Vac or Vdc 69 – 100 Vac or Vdc 138 – 200 Vac or Vdc

Each BE1-951 is delivered without the contact-sensing jumpers installed for operation in the higher end of

the control voltage range. If the contact sensing inputs are to be operated at the lower end of the control

voltage range, the jumpers must be installed. See Section 12, Installation, for details on how to set the

jumper positions in the contact sensing input circuits.

The contact sensing inputs circuits are polarity sensitive. When an ac wetting voltage is applied, the input

signal is half-wave rectified by the opto-isolator diodes. The contact sensing inputs drive BESTLOGIC

variables IN1, IN2, IN3, and IN4. Each contact sensing input is completely programmable so meaningful

labels can be assigned to each input and the logic-high and logic-low states. Section 7, BESTLOGIC

Programmable Logic, provides more information about using contact sensing inputs in your

programmable logic scheme.

Digital Input Conditioning Function

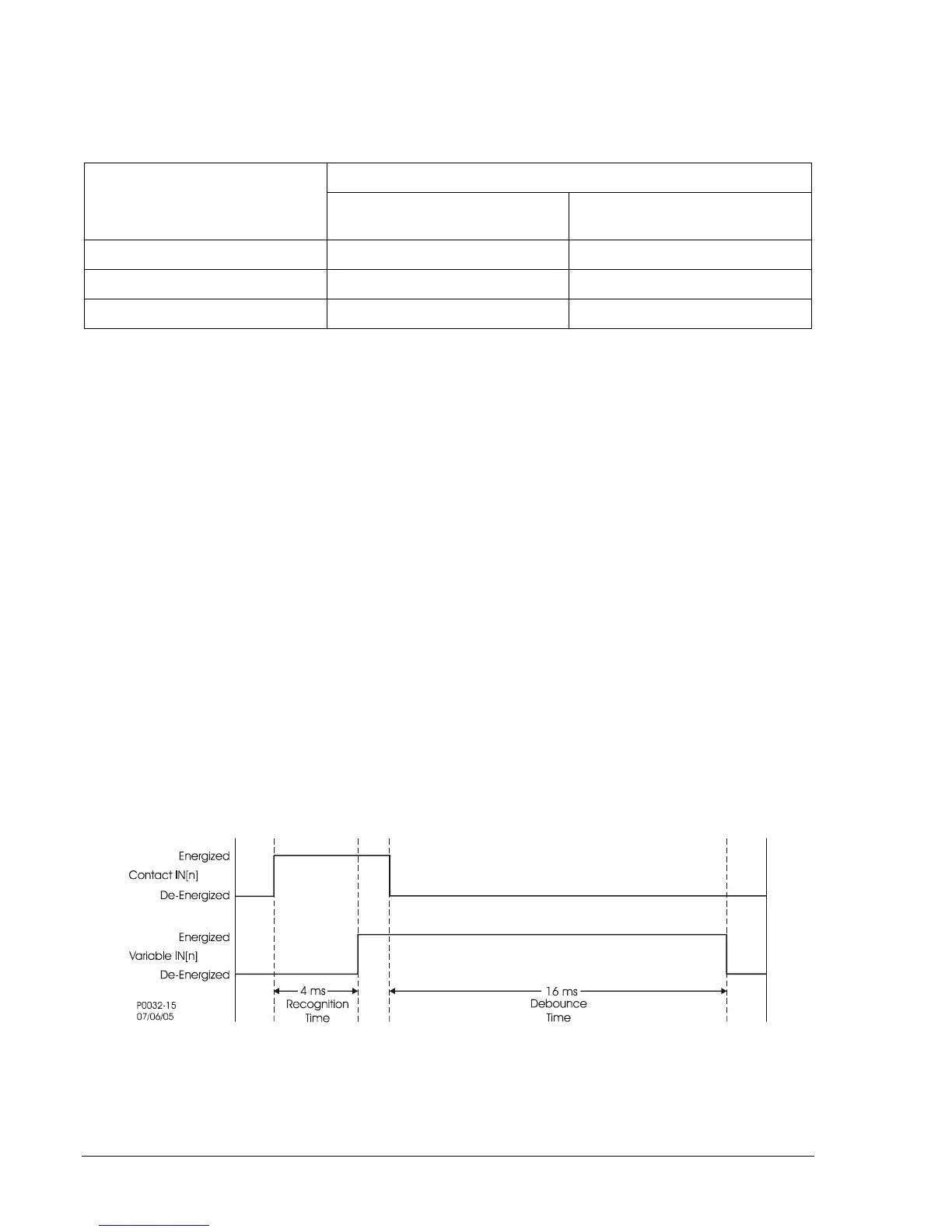

Status of the contact sensing inputs is checked 12 times per cycle. (See Figure 3-3.) When operating on

a 60-hertz power system, the result is the input status being sampled every 1.4 milliseconds (1.6

milliseconds on 50 hertz systems). User-settable digital contact recognition and debounce timers

condition the signals applied to the inputs. These parameters can be adjusted to obtain the optimum

compromise between speed and security for a specific application. Digital input conditioning is evaluated

every quarter cycle.

If the sampled status of a monitored contact is detected as energized for the recognition time, the logic

variable changes from a de-energized (logic 0 or FALSE) state to an energized (logic 1 or TRUE) state.

Once contact closure is recognized, the logic variable remains in the energized state until the sampled

status of the monitored contact is detected to be de-energized for a period that is longer than the

debounce time. At this point, the logic variable will change from an energized (logic 1 or TRUE) state to a

de-energized (logic 0 or FALSE) state.

Figure 3-3. Digital Input Conditioning Timing Diagram

Loading...

Loading...