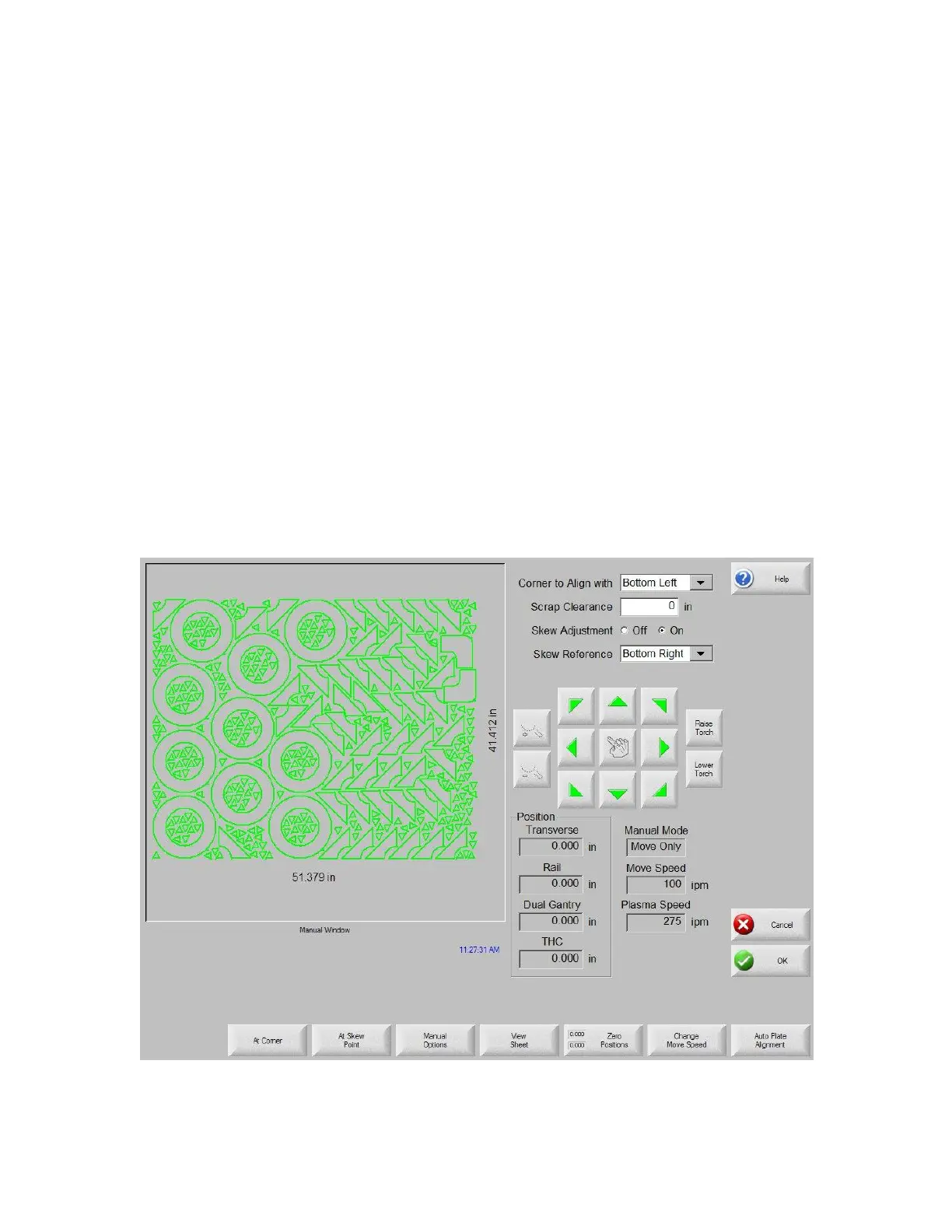

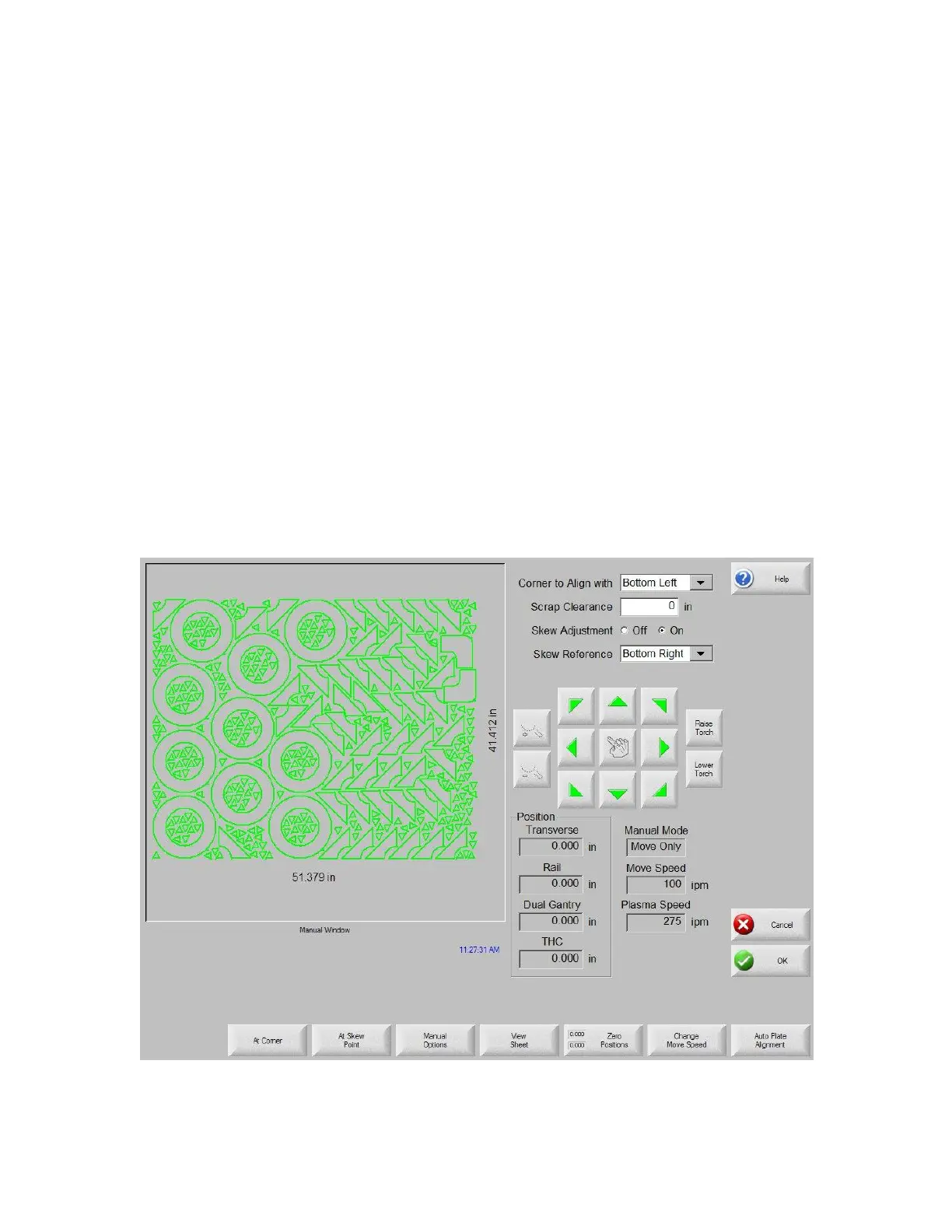

Part Options 249

Align

This screen is used to align the current part in memory into one of the four corners of the plate for

cutting. This function also allows for skewed plates to be taken into account when aligning the part.

Part Alignment is used to position a part or nest of parts, on to a squared plate so that it will fit on to

the plate. This is commonly with parts that have an internal pierce point such as a flange.

Skew Alignment is used to position a part or nest of parts, on to a skewed or angled plate so that it

will fit accurately onto the plate without going over the edges. This is commonly used with a nest of

parts which has little margin of error for placement of the nest on to the plate.

Instructions for use

To Align a part to the plate, follow these steps:

1. Set parameters to those needed for aligning your part in the upper right corner of the screen.

2. Move the torch to the first corner location (“Corner to Align with”) using the jog keys.

3. Press the “At Corner” soft key.

4. If performing a Part Alignment, go to step 7. If performing a Skew Alignment, go to step 5.

5. Move the torch to a point along the edge of the plate towards the selected “Skew Reference”.

6. Press the “At Skew Point” soft key.

7. Press the OK soft key. The machine will move to the start point for the part and return to the

Main screen ready for cutting.

Corner to Align with

Loading...

Loading...