Motion Overview 406

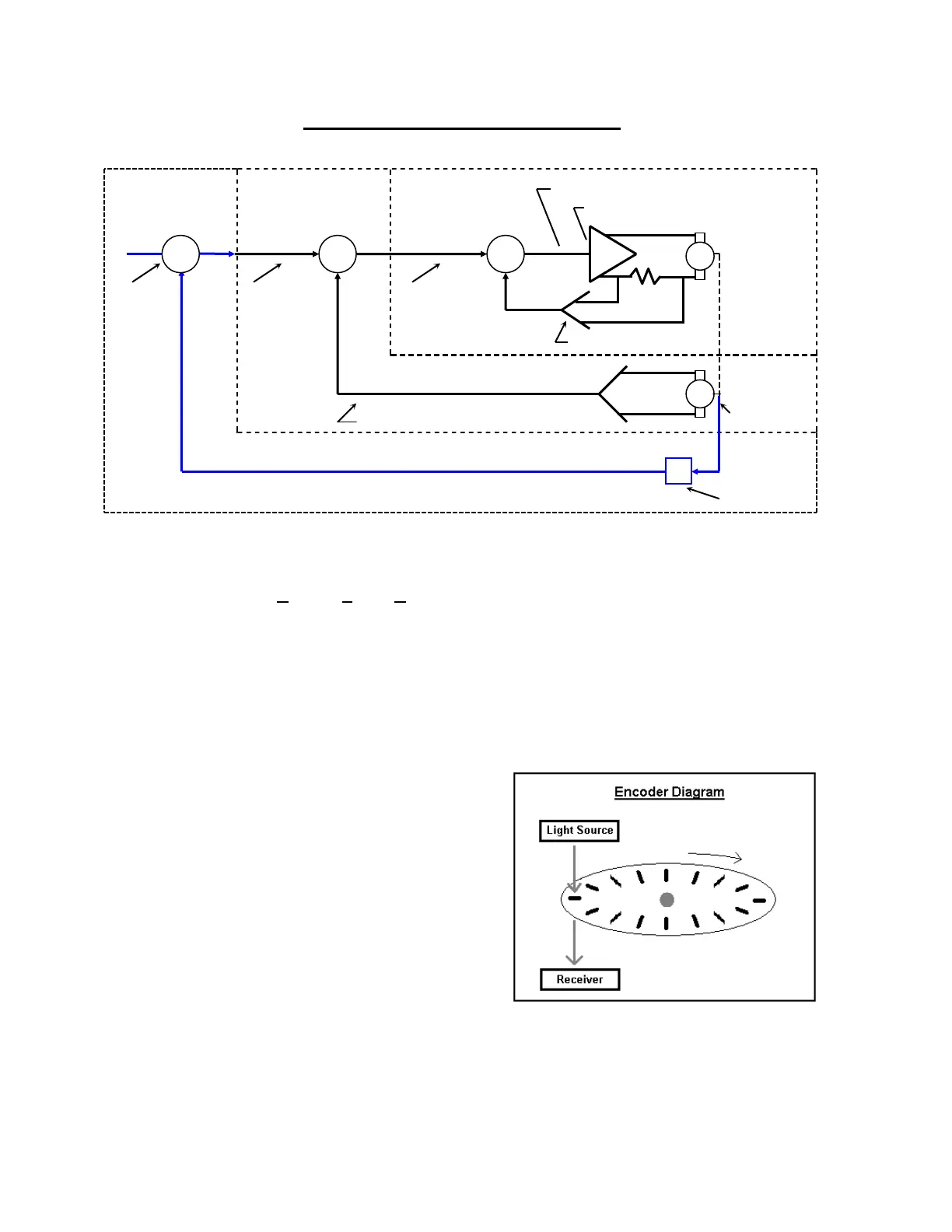

Typical Velocity and Position Loop System

The Motion Command starts as Digital Output within the control and then is converted to a +/- 10VDC

Analog Output for use by the motors. This conversion of the Motion Command within the control is

referred to as the DAC (Digital to Analog Converter) Output and is performed by the Motion Control

Card. The Analog Output when it comes out of the control is sent to a drive amplifier that then steps

up the voltage output to the motor and creates motion. Also, there is usually a linear relationship

between the voltage sent and the machine speed (i.e. 10 volts = maximum machine speed, 5 volts =

half max machine speed). Additionally, the polarity of the output (DAC Polarity +/-) to the amplifier

will dictate the direction of the motor rotation. In most applications and in the following application

description the feedback device is an Encoder.

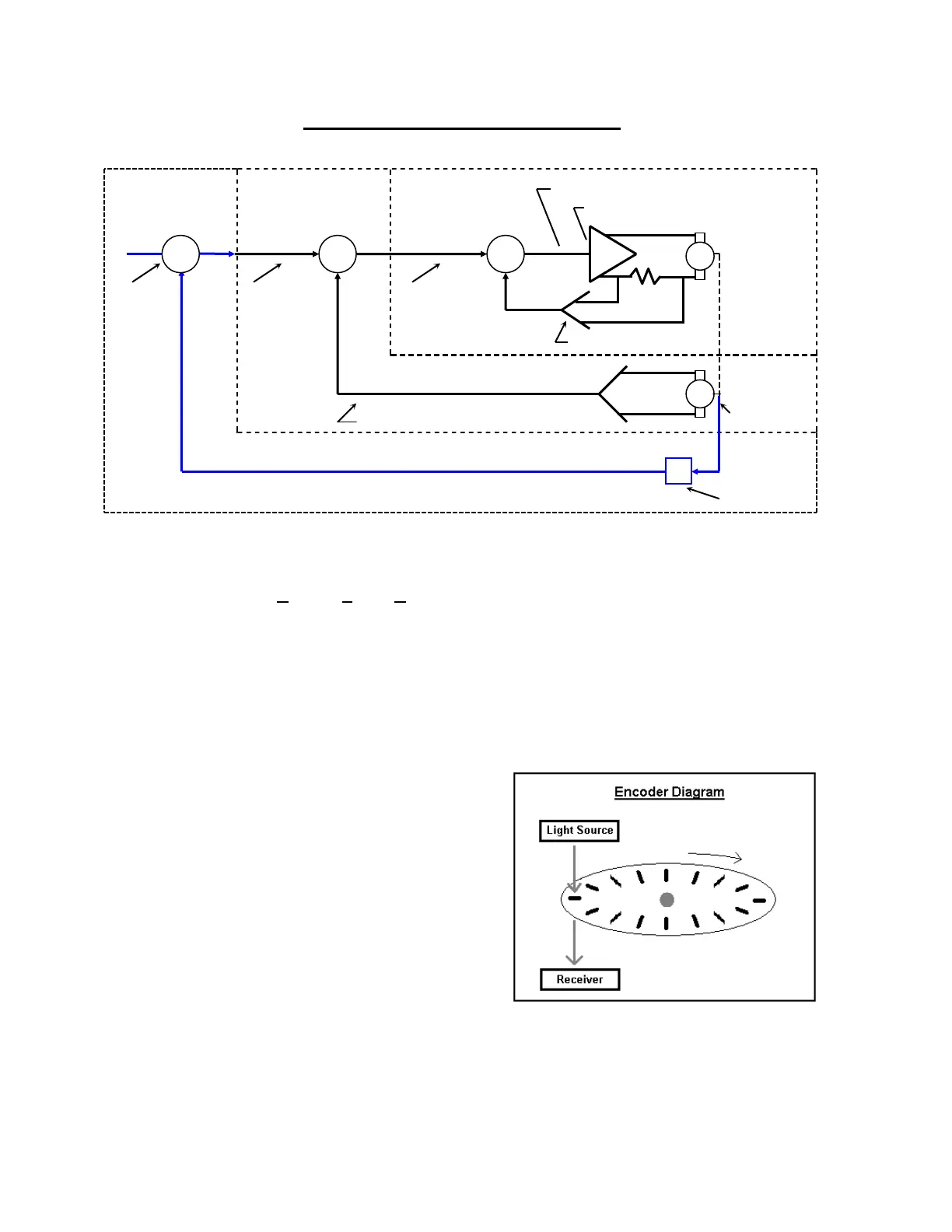

1a) What is an Encoder?

Essentially, an Encoder is a feedback device

that provides signal pulses as the motor turns.

The diagram at the right illustrates the basic

concept of an Encoder. Although this does

not represent all Encoder / feedback device

technology, this illustration provides a visual

aid to help understand the process.

The illustration shows a disk with small holes

cut out along the outer edge. The light source

provides a beam of light projected downward

through the holes in the disk. As the disk

turns on the end of the motor shaft, the light passes through the disk creating pulses.

The Receiver below the disk picks up the pulsed light source and sends that

feedback to the control.

Current

Command or

Velocity Error

Signal

Loading...

Loading...