Example 3: Differences in Starting Cam Operation of the Slave Axis for Differences in

StartMode

Y

ou can use StartMode to specify whether the value that is specified for MasterStartDistance (Master

Following Distance) is treated as an absolute value or a relative value.

This example describes the differences in starting cam operation of the slave axis for differences in

StartMode. The cam table settings are the same as in the previous example.

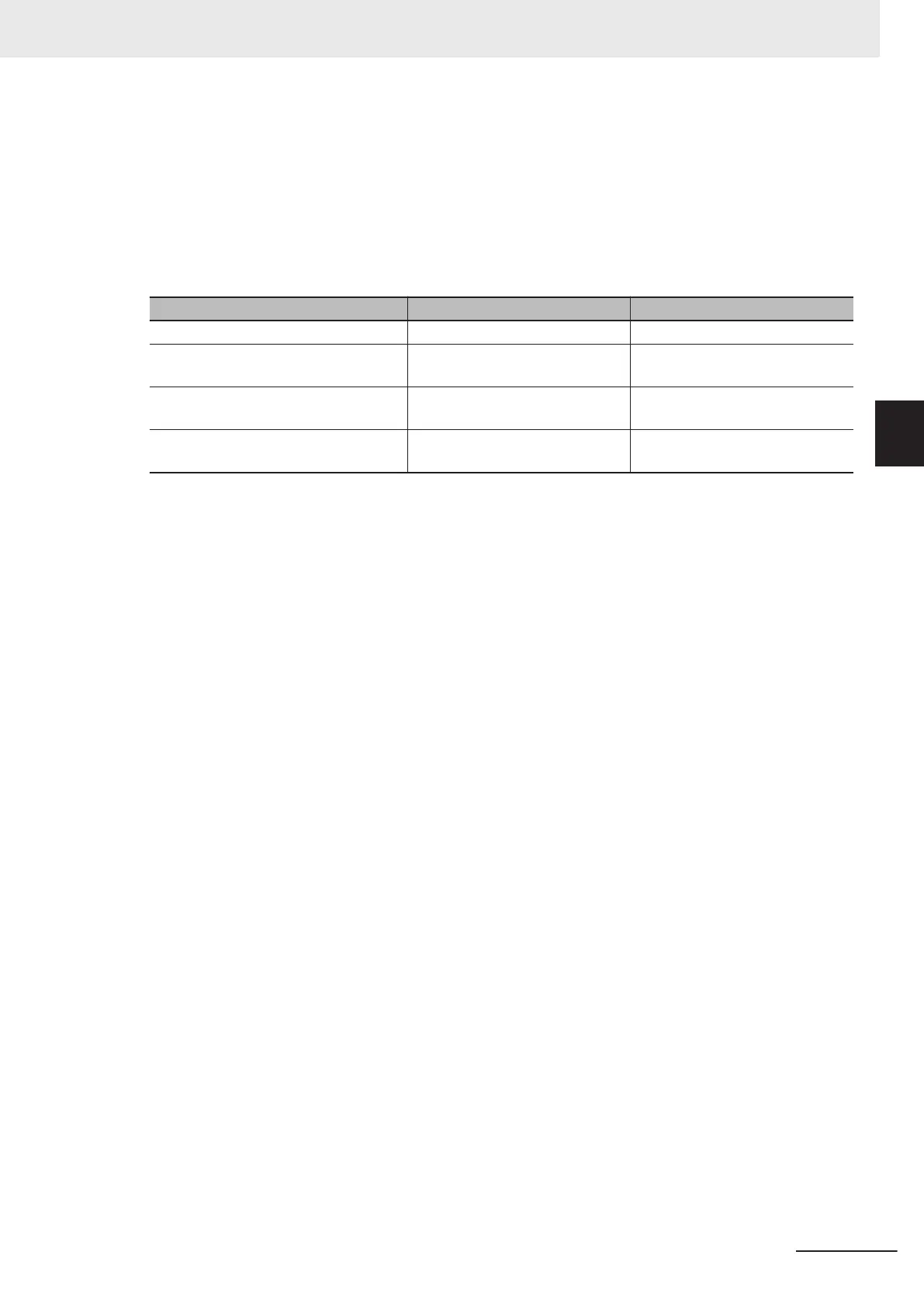

The conditions for starting cam operation are given in the following table.

Input variable Condition 1 Condition 2

Periodic (Periodic Mode) TRUE: Periodic TRUE: Periodic

StartMode _mcAbsolutePosition (Absolute

Position)

_mcRelativePosition (Relative

Position)

StartPosition (Cam Table Start Posi-

tion)

40 40

MasterStartDistance (Master Following

Distance)

80 80

For both conditions 1 and 2, the InCam (Cam Motion) output variable changes to TRUE when the

master axis passes 40°. For condition 1, StartMode is set to _mcAbsolutePosition (absolute position),

so the InSync output variable changes to TRUE and the slave axis starts cam operation when the

master axis passes 80°.

For condition 2, StartMode is set to _mcRelativePosition (relative position), so the InSync

output varia-

ble changes to TRUE and the slave axis starts cam operation when the master axis passes 120°(= 40°

+ 80°).

3 Axis Command Instructions

3-185

NY-series Motion Control Instructions Reference Manual (W561)

MC_CamIn

3

Function

Loading...

Loading...