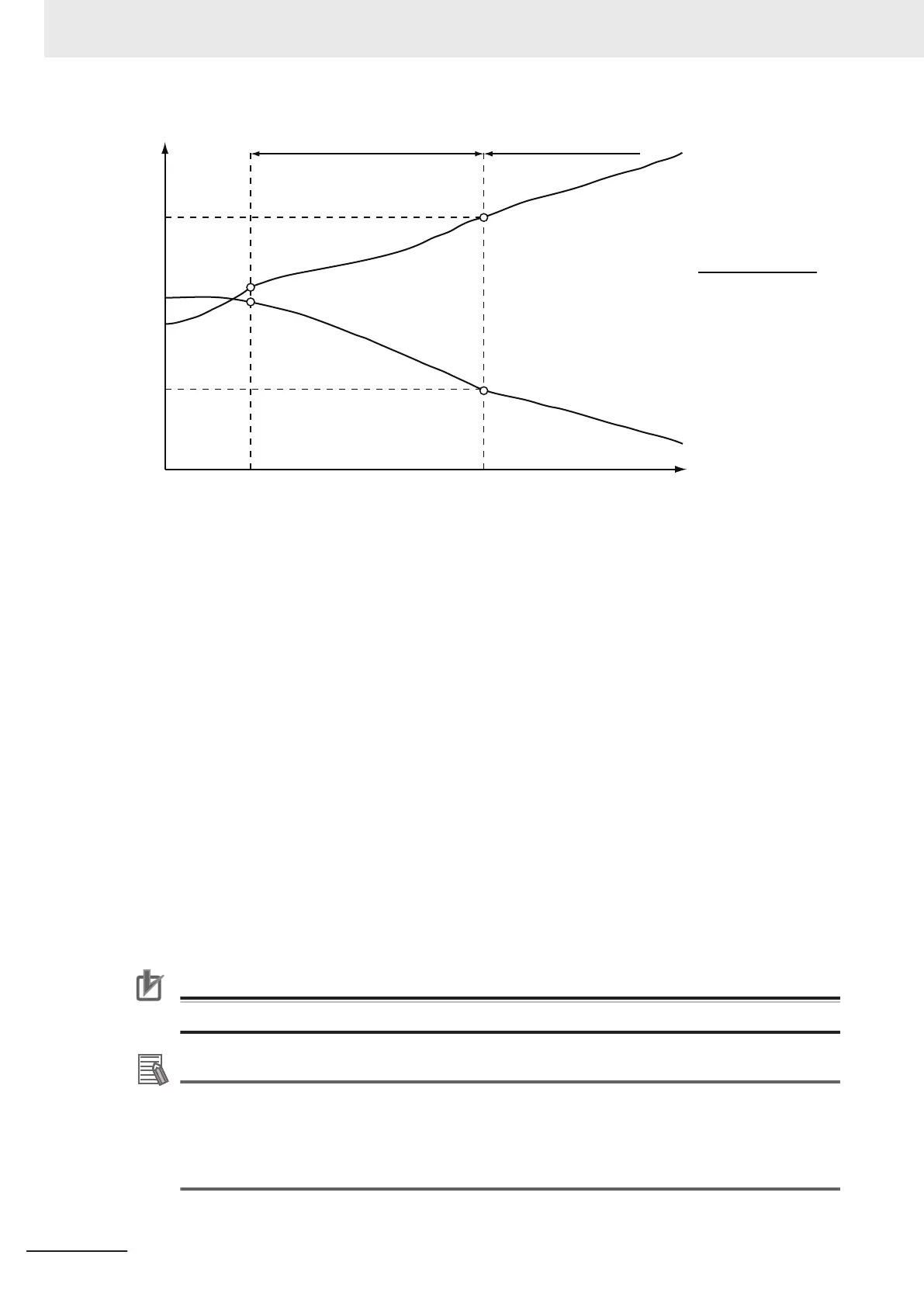

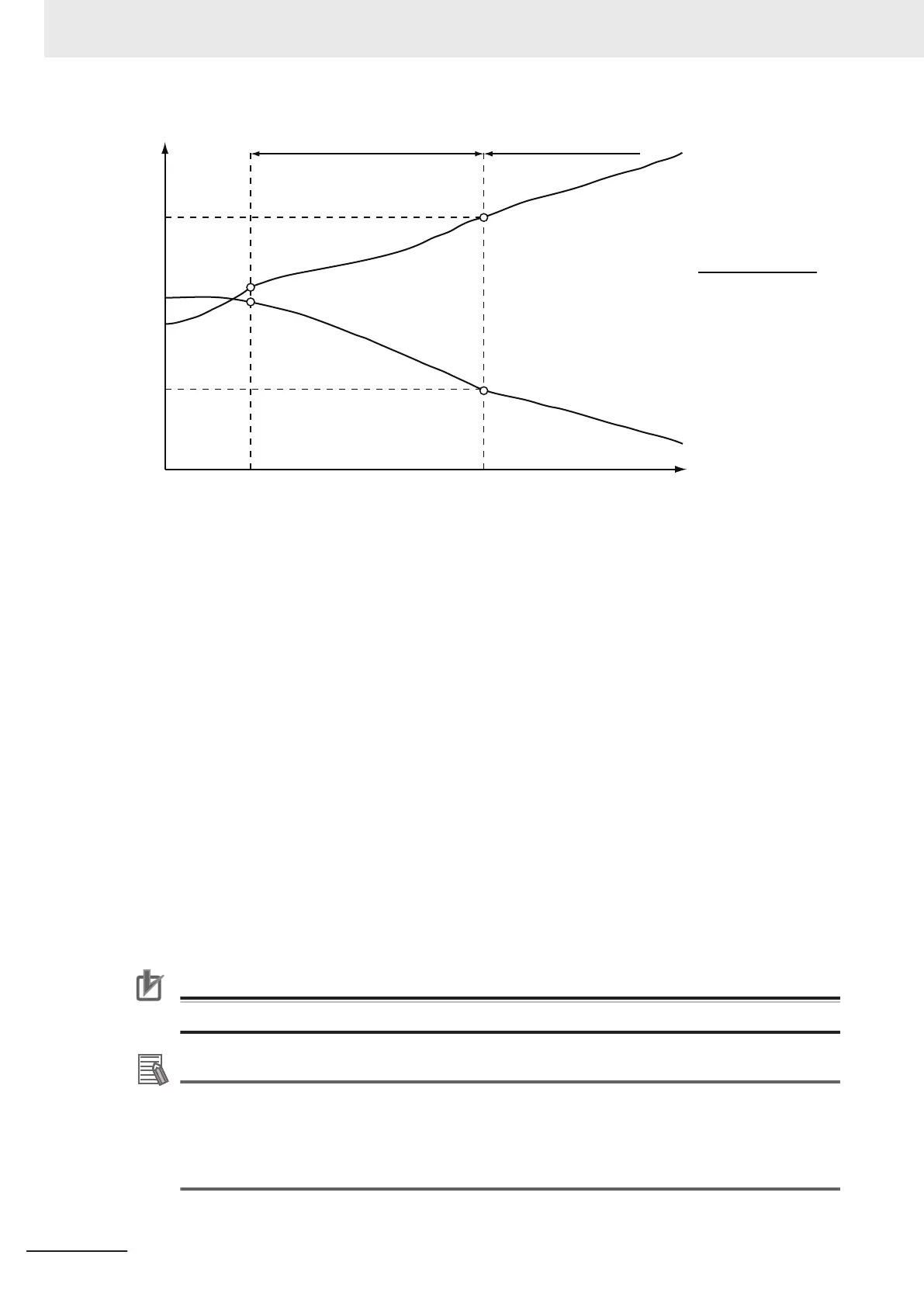

Execute

Catching Phase InGear phase

Master

Slave

RatioDenominator

RatioNumerator

Position

Time

Travel distance of slave axis

= Travel distance of master axis ×

• Electronic gear operation starts when Execute changes to TRUE.

ReferenceType (Position Type Selection)

You can select one of the following position types.

•

_mcCommand: Command position (value calculated in the previous task period)

The master axis command position that was calculated in the previous task period is used for the

current period.

The command value that was calculated for the master axis in the last periodic task is used to calcu-

late the command position of the slave axis in the current period.

• _mcFeedback: Value obtained in the same task period

The actual position of the master axis that was obtained in the same task period is used.

• _mcLatestCommand: Command position (value calculated in the same task period)

The command position of the master axis that was calculated in the same task period is used.

This enables the use of information that is more recent than for _mcCommand. However, the axis

number of the master axis must be set lower than the axis number of the slave axis.

If the axis number of the slave axis is lower than the axis number of the master axis, Error will

change to TRUE. A Master/Slave Axis Numbers Not in Ascending Order error (error code: 5438

hex) will be output to ErrorID.

Precautions for Correct Use

Here, the task period is the primary period. The periodic task is the primary periodic task.

Additional Information

The command position that is calculated in the same task period enables greater precision in

synchronization than the command position that was calculated in the previous task period.

However

, the axis number set for the Master (Master Axis) in the system-defined variable for

motion control must be lower than the axis number set for the Slave (Slave Axis) in the system-

defined variable for motion control.

3 Axis Command Instructions

3-250

NY-series Motion Control Instructions Reference Manual (W561)

Loading...

Loading...