Precautions for Correct Use

Here, the task period is the primary period. The periodic task is the primary periodic task.

Additional Information

The command position that is calculated in the same task period enables greater precision in

synchronization than the command position that was calculated in the previous task period.

However

, the axis number set for the Master (Master Axis) in the system-defined variable for

motion control must be lower than the axis number set for the Slave (Slave Axis) in the system-

defined variable for motion control.

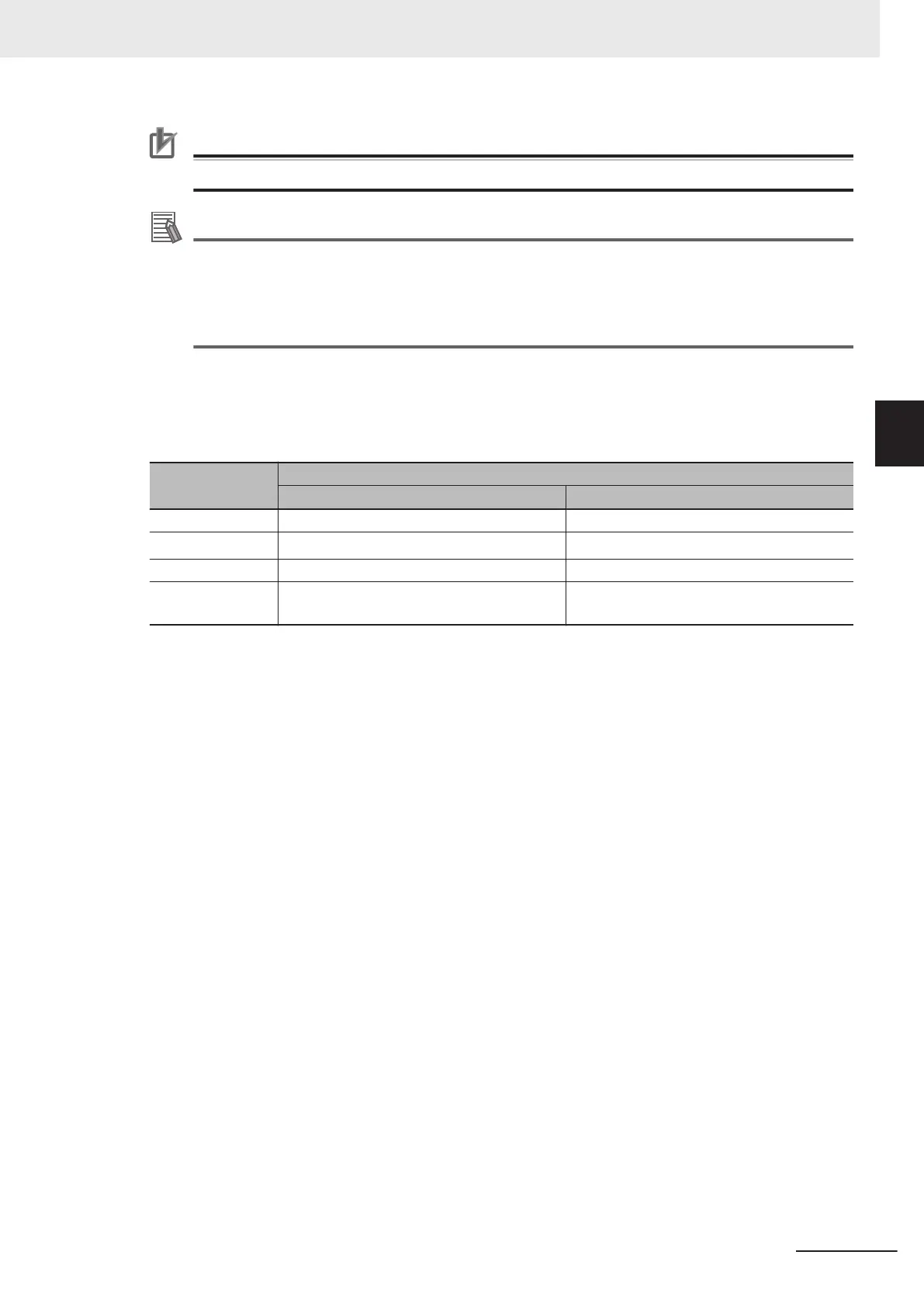

Relationship between Axis Types and Position Types

The relationship between the axis types that you can monitor and position types that is monitored is

shown below

.

Axis Type

ReferenceType

_mcCommand or _mcLatestCommand _mcFeedback

Servo axis OK OK

Encoder axis

No

*1

OK

Virtual servo axis OK OK

Virtual encoder

axis

No

*1

OK

*1. A Position Type Selection Out of Range error (error code: 5430 hex) occurs when the instruction is execut-

ed.

SlaveDistance (Slave Axis Travel Distance), MasterDistance (Master Axis Travel

Distance), MasterDistanceInACC (Master Distance in Acceleration), and Master-

DistanceInDEC (Master Distance in Deceleration)

The velocity and position of the slave axis are determined by the ratio of the travel distances of the

master axis and the slave axis as shown in the following figure.

The master following distance shown in the following figure represents the position where the sync

start condition was met.

Master Axis T

ravel in Positive Direction

3 Axis Command Instructions

3-299

NY-series Motion Control Instructions Reference Manual (W561)

MC_MoveLink

3

Function

Loading...

Loading...