The DeviatedV

alue (Following Error between Axes) is the shorter distance between the command

current position of the Master (Master Axis) and the command current position of the Slave (Slave

Axis) in the range of the ring counter.

The sign of the DeviatedValue (Following Error between Axes) is the sign for the shorter direction,

as given below.

• If the command current position of the Master (Master Axis) is greater than or equal to the com-

mand current position of the Slave (Slave Axis), the value is positive.

• If the command current position of the Master (Master Axis) is less than the command current

position of the Slave (Slave Axis), the value is negative.

ReferenceType (Position Type Selection) Set to _mcFeedback

The DeviatedValue (Following Error between Axes) is the shorter distance between the actual cur-

rent position of the Master (Master Axis) and the actual current position of the Slave (Slave Axis) in

the range of the ring counter.

The sign of the DeviatedValue (Following Error between Axes) is the sign for the shorter direction,

as given below.

• If the actual current position of the Master (Master Axis) is greater than or equal to the actual

current position of the Slave (Slave Axis), the value is positive.

• If the actual current position of the Master (Master Axis) is less than the actual current position of

the Slave (Slave Axis), the value is negative.

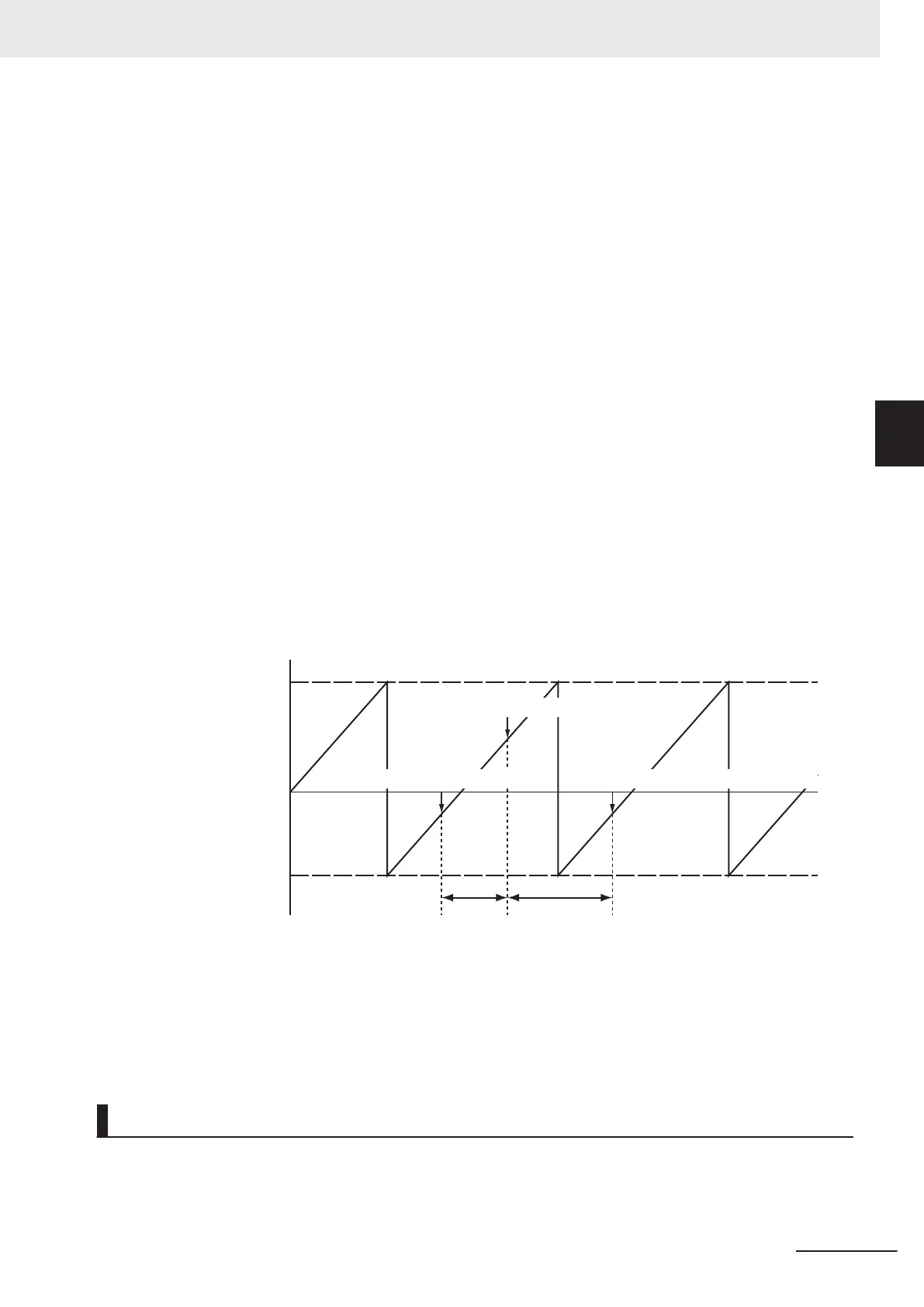

DeviatedValue (Following Error between Axes) Calculation Example in Rotary Mode when

ReferenceType (Position Type Selection) Is Set to _mcCommand

0

70 100

Slave command current position: −20

Master command current position: 50

Slave command current position: −20

|DeviatedValue| is 70 (because 70 is less than 100).

The sign is positive because the command current position of

the

Master is greater than or equal to the command current

position of the Slave, so the DeviatedValue is +70.

Mod

ulo maximum

position setting value:

100

Modulo minimum

position setting value:

−70

If ReferenceT

ype (Position Type Selection) is _mcFeedback in Rotary Mode, the "command current

position" in the above diagram would be the "actual current position".

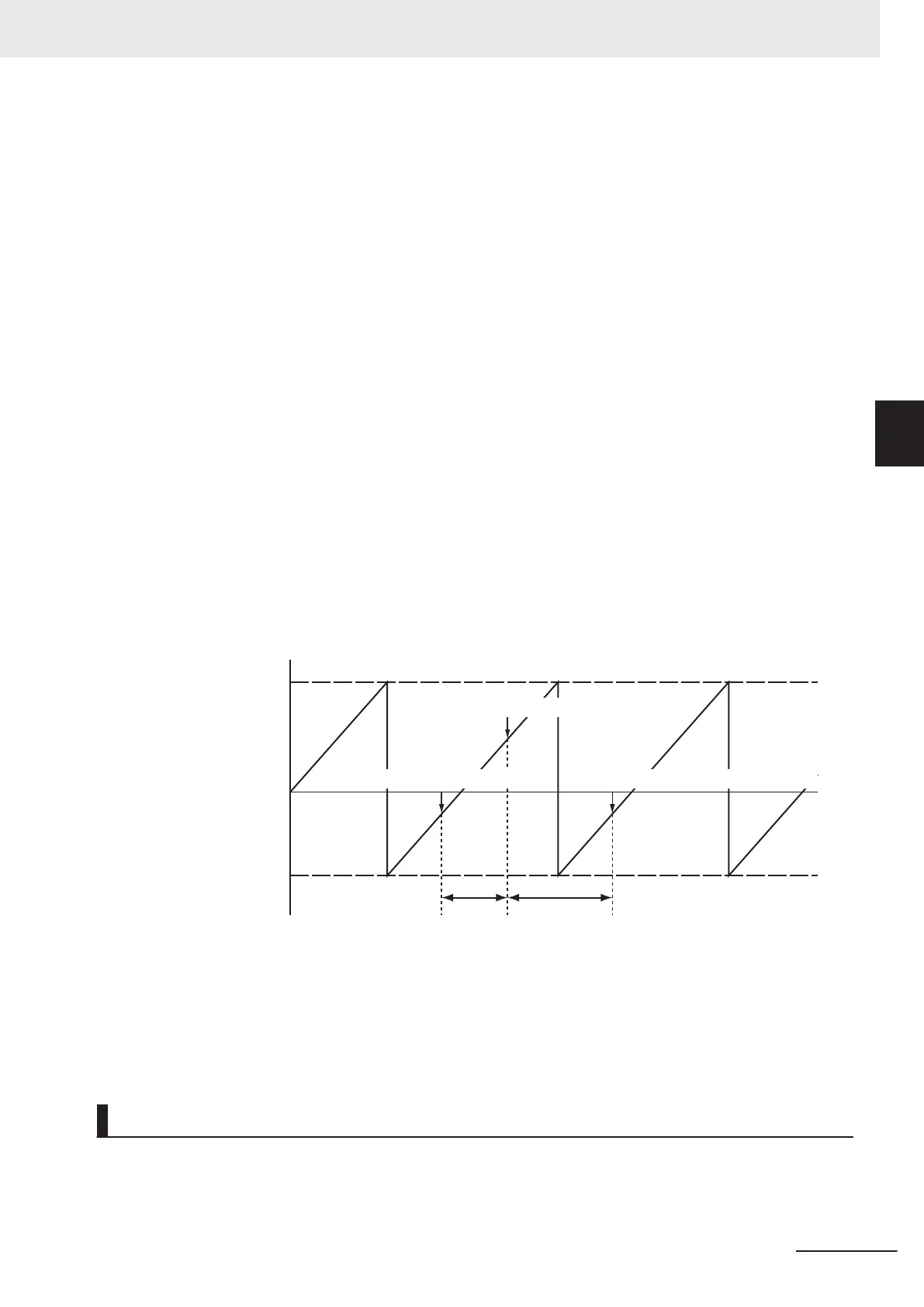

Timing Charts

An error for this instruction does not affect the operation of the axis or axes group.

A timing chart is given below for when PermittedDeviation (Permitted Following Error) is 10.0.

3 Axis Command Instructions

3-389

NY-series Motion Control Instructions Reference Manual (W561)

MC_AxesObserve

3

Function

Loading...

Loading...