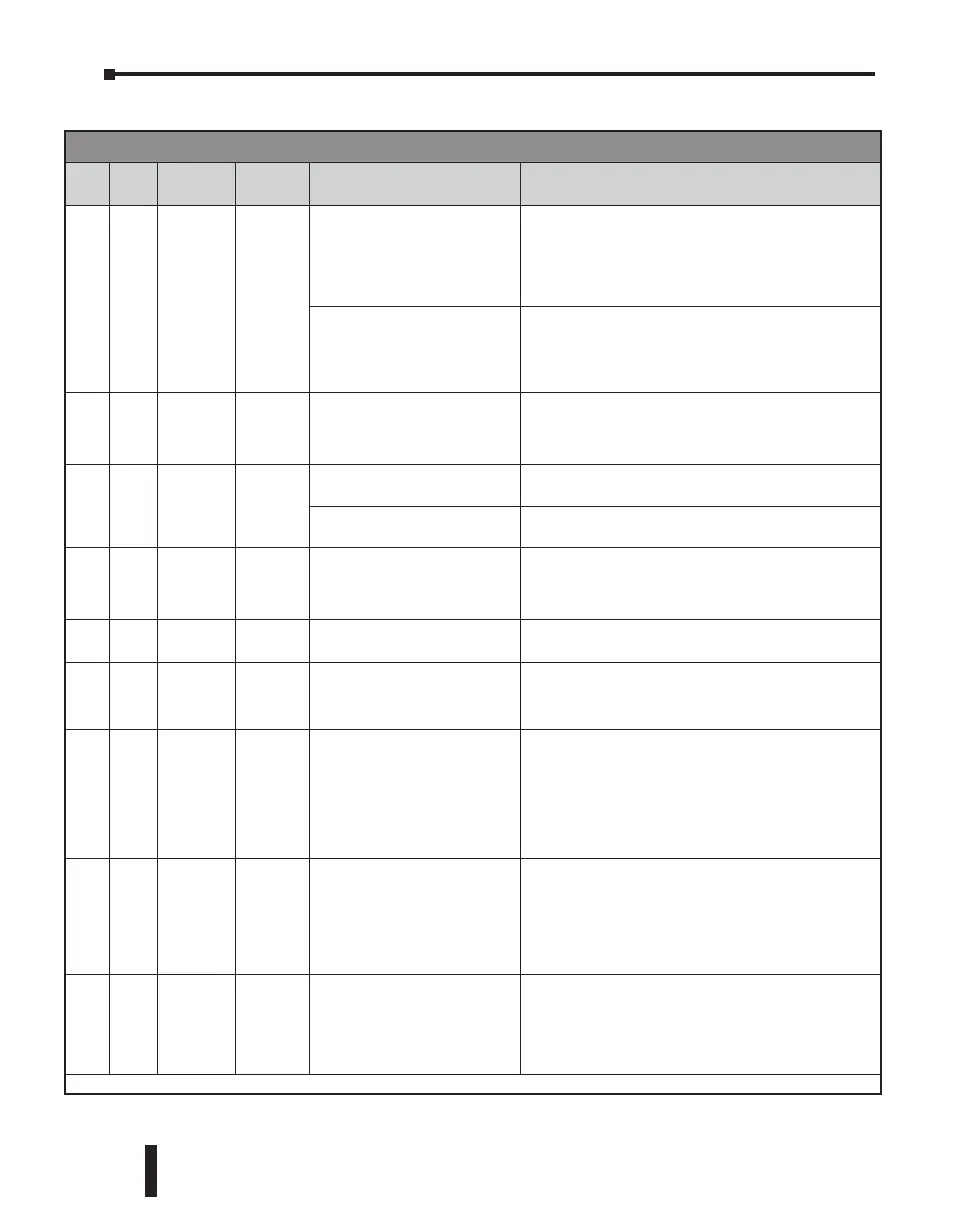

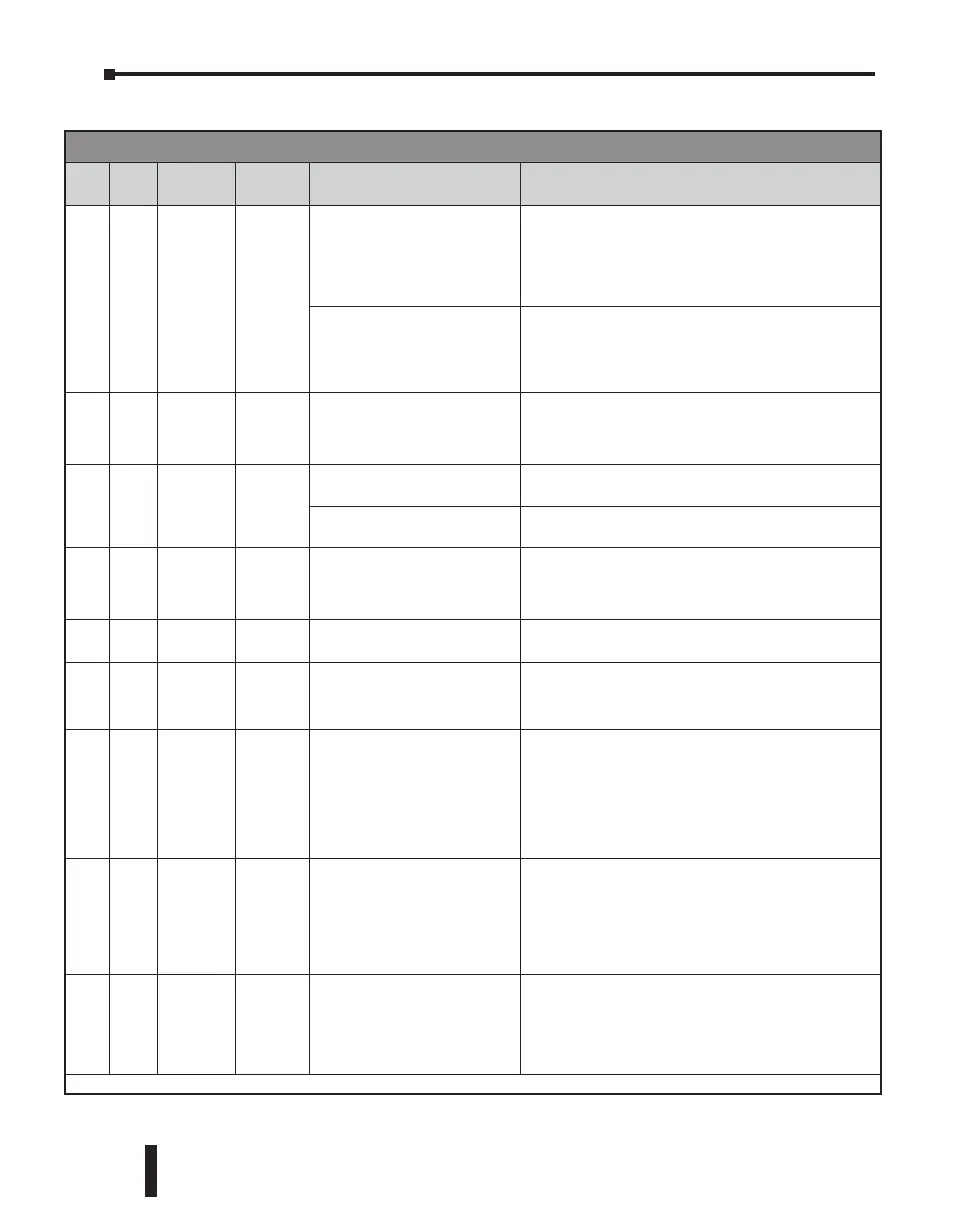

Error Codes (continued)

PLC Error Codes

Error

Code

Status

Flag*

Error

Name

Category Causes Solutions

103 SC22

I/O Config

Error

Error

At least one I/O module was

removed from the CLICK PLC

during operation.

Power off the CLICK PLC and check the connection of the

I/O modules. Then power on the CLICK PLC again. If the

problem remains, connect the CLICK software to the PLC

and check the System Configuration. If there is any I/O

module that is not shown in the System Configuration,

replace it.

The PLC unit can not access one

or more I/O modules.

Connect the CLICK software to the CLICK PLC and open

the System Configuration window. If there is any I/O

module that is used in the PLC system but not shown in

the System Configuration window, replace the I/O module.

104 SC23

Memory

Check Error

Error There is a memory check error.

Power cycle the CLICK PLC. If the same error occurs

again, download the project again and/or try the ‘Reset to

Factory Default’ command. If the same error still occurs,

replace the PLC unit.

105 SC24

Project File

Error

Error

There is no project file in the

CLICK PLC.

Download a project file into the CLICK PLC.

The project file stored in the

CLICK PLC is corrupted.

Download the project file into the CLICK PLC again.

106 SC25

Firmware

Version

Error

Error

The project file was written on a

newer version of CLICK software.

The firmware in the CLICK PLC is

too old to execute the project.

Connect the CLICK software to the CLICK PLC and update

the firmware of the PLC unit.

107 SC26

Watchdog

Timer Error

Error

The PLC scan time exceeded the

watchdog timer setup.

Connect the CLICK software to the PLC and check the

maximum PLC scan time and the watchdog timer setup.

108 SC26

Interrupt

Watchdog

Timer Error

Error

The PLC scan time exceeded the

watchdog timer setup.

The watchdog timer was exceeded while executing an

Interrupt Program. Reduce the occurrences of Interrupts,

or reduce the executing time of the Interrupt Programs to

prevent this error.

201 SC27

Lost SRAM

Data

Warning

The data in the SRAM was

lost while the CLICK PLC was

powered off.

The Basic PLC units do not have a battery back-up, but

they have a capacitor that will hold memory for a few

days. The data in the SRAM is lost if the CLICK PLC

is powered off for long enough for the capacitor to

discharge. In this case, the CLICK PLC initializes the data

in the SRAM automatically. This also applies to Standard

and Analog PLC units if a battery is not installed.

202 SC28

Battery Low

Voltage

Warning

Battery voltage is too low to

retain data in the SRAM.

Replace the battery (ADC part #: D2-BAT-1).

Also, set the new battery installation date and the

anticipated replacement date in the CLICK programming

software if the Battery Replacement Notification option is

selected.

(Pull-down menu: Setup > Battery Backup Setup)

203 SC29

Battery

Replace-

ment

Warning

The anticipated battery

replacement date has passed.

Replace the battery (ADC part #: D2-BAT-1).

Also, set the new battery installation date and the

anticipated replacement date in the CLICK programming

software.

(Pull-down menu: Setup > Battery Backup Setup)

* The SC bits are turned ON when the related errors occur.

Error code table continued on next page.

CLICK PLC Hardware User Manual, 6th Edition, Rev. F – C0-USER-M

6–12

Chapter 6: Troubleshooting

Loading...

Loading...