Processor paper advance operation

1/4

5. Operation sequence

56100

56100

Proc essor paper adv ance operation

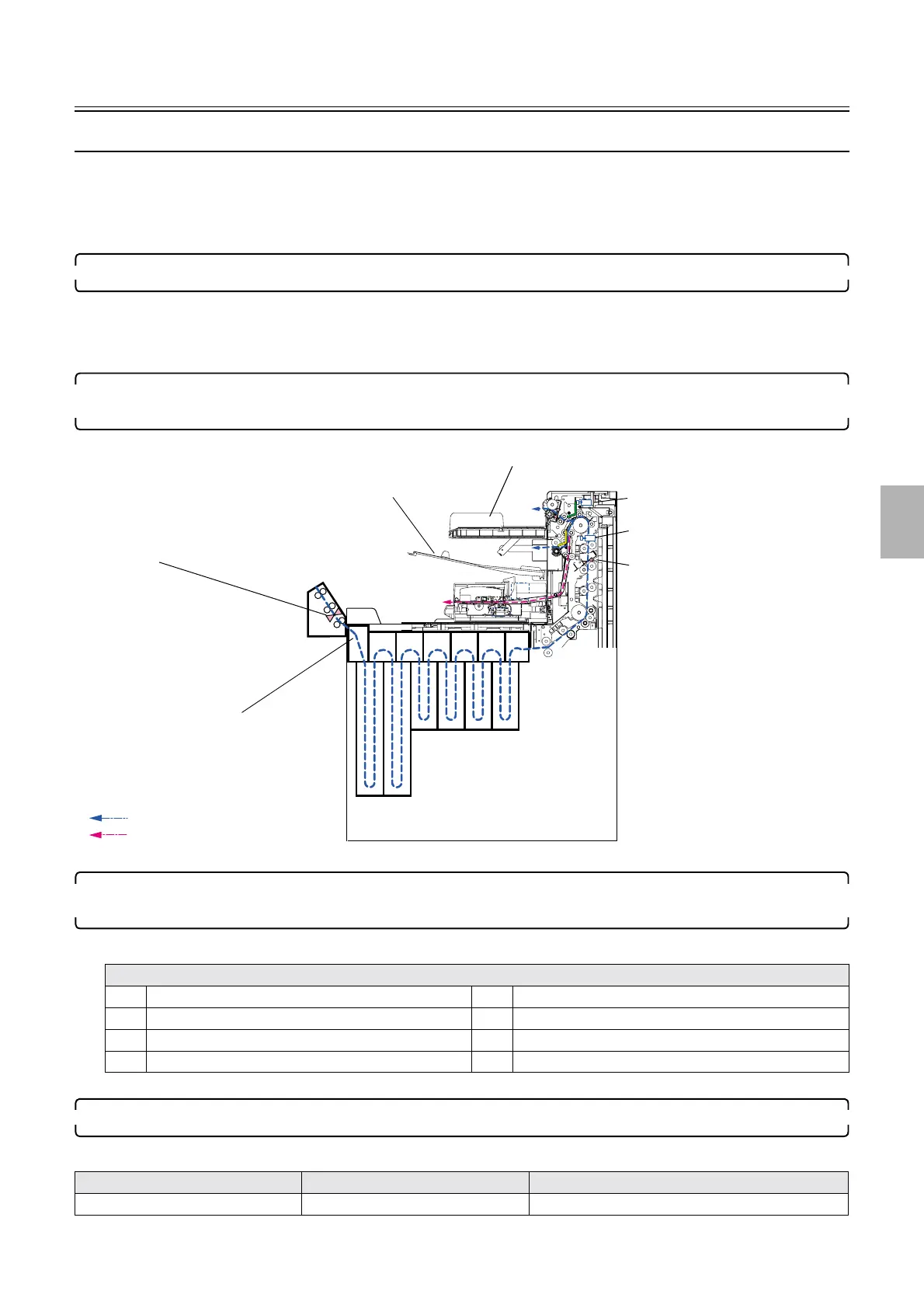

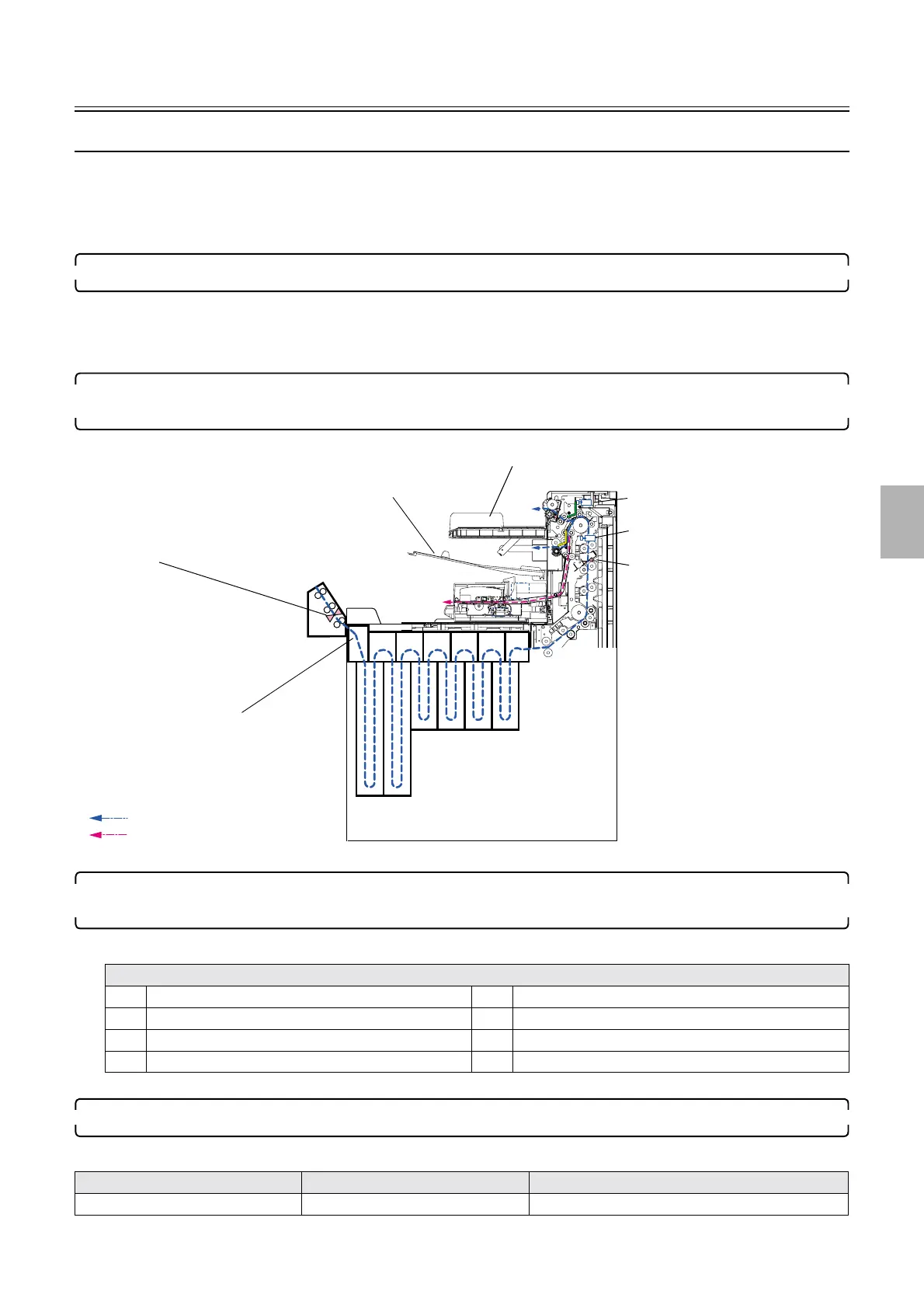

Paper advance operation of the processor (normal prints)

This section explains the process that begins with the normal print paper entering the processor and ends with it being output to either the

print conveyor unit or the print receiving tray (large). It is a precondition that the temperature adjustment of the processing solution is

completed.

Paper advance operation of setup print varies normal print operation.

1. The processor enters the following states when the paper is loaded. ☞ 55100

• Processor drive motor: ON

• Dryer fan: ON

• Dryer heater: ON

2. The back edge of the paper passes through paper sensor 2 (left, center, right), which is located in the

processor loading unit.

3. When the paper leading edge passes position A in the above figure, the process signal is transmitted to

the processor by the printer.

• The following data are transmitted to the processor by the printer.

4. Paper arrives at the dryer rack.

• The paper advance procedures listed below vary depending on print paper width and advance length.

Transmission data list

1 Information of paper advance length 5 Information of print counts

2 Information of paper width 6 Information of paper advance position

3 Information of paper surface 7 Information of paper lane

4 Order information 8 Information of splice

Paper width Advance length Paper advance procedure references

• Between 82.5 and 152 mm • Between 82.5 and 305 mm ☞Paper output to the print conveyor unit

Paper sensors 2 (left, center and right)

Position A

Print conveyor unit

Print receiving tray (large)

Normal Print

Setup print

Dryer selection solenoid 1

Dryer selection solenoid 2

Dryer Lane Select Sensor

G085226

Distributed by: minilablaser.com

Loading...

Loading...