Colorimeter unit operation

1/3

5. Operation sequence

56610

56610

Automatic color measurement operation for setup prints

This section explains the automatic color measurement operation for setup prints.

NOTE

• When attention messages or error messages is shown after failed to measure the setup print, the setup print is output without

registering the result.

• When the measurement would be failed and the attention message

☞No. 01029The measurement failed. Measure it again. is

shown, you can measure the setup print again if inserting the print to the colorimeter unit manually.

1. The print was inserted to the colorimeter unit.

2. Detects the paper leading end by paper sensor 1, and releases the pressure of the measurement position.

• Paper sensor 1: LIGHT to DARK

• Pressure solenoid: ON

If paper sensor 1 does not turn DARK

• ☞No. 05535

Paper has jammed in the processor section.

3. Starts to advance the paper after detected the paper leading end by paper sensor 1.

• Paper sensor 1: DARK

• Paper advance motor: ON (forward)

If paper sensor 1 turns LIGHT

• ☞No. 01552-00001

The paper in the Colorimeter is too short. It cannot be measured.

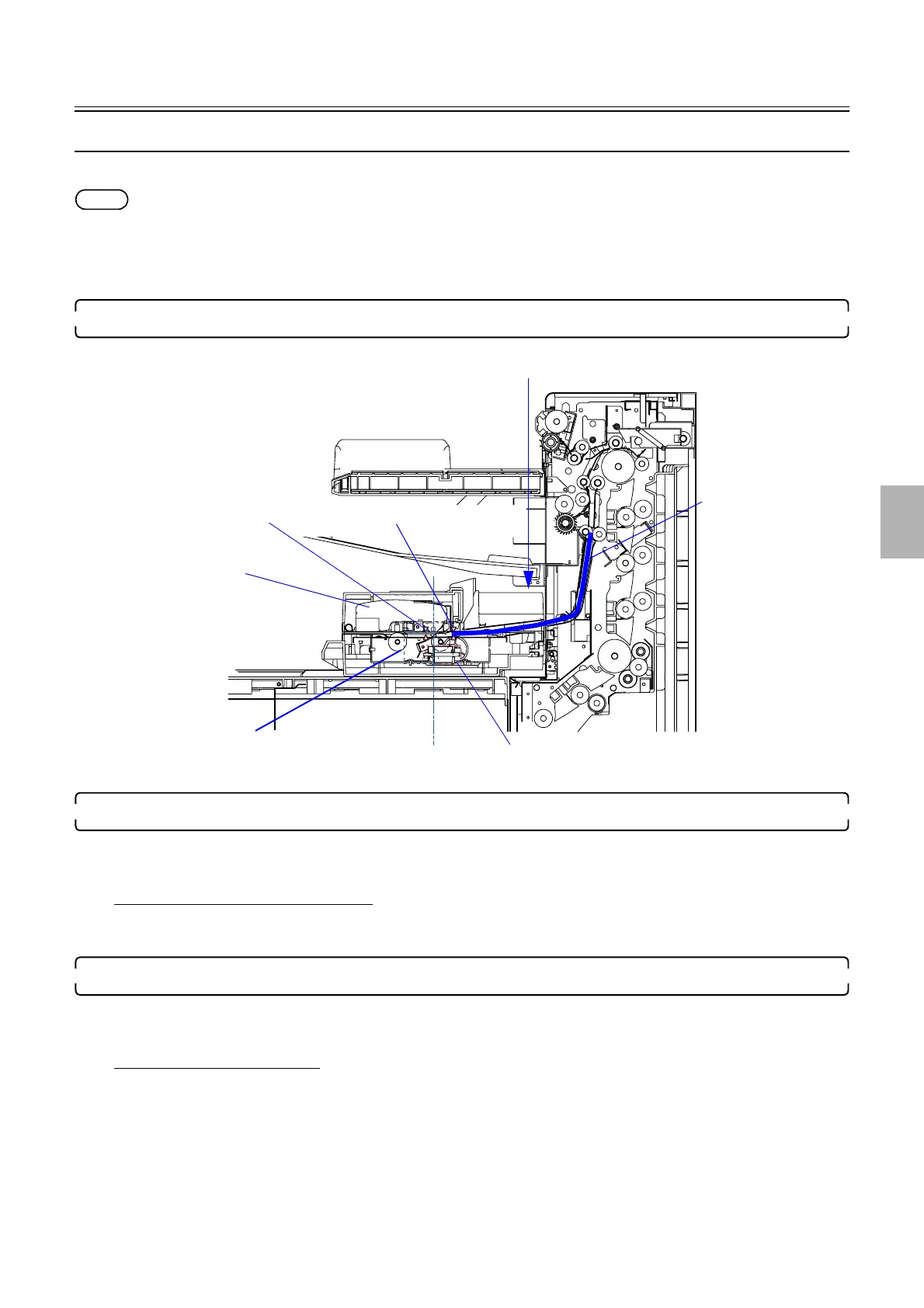

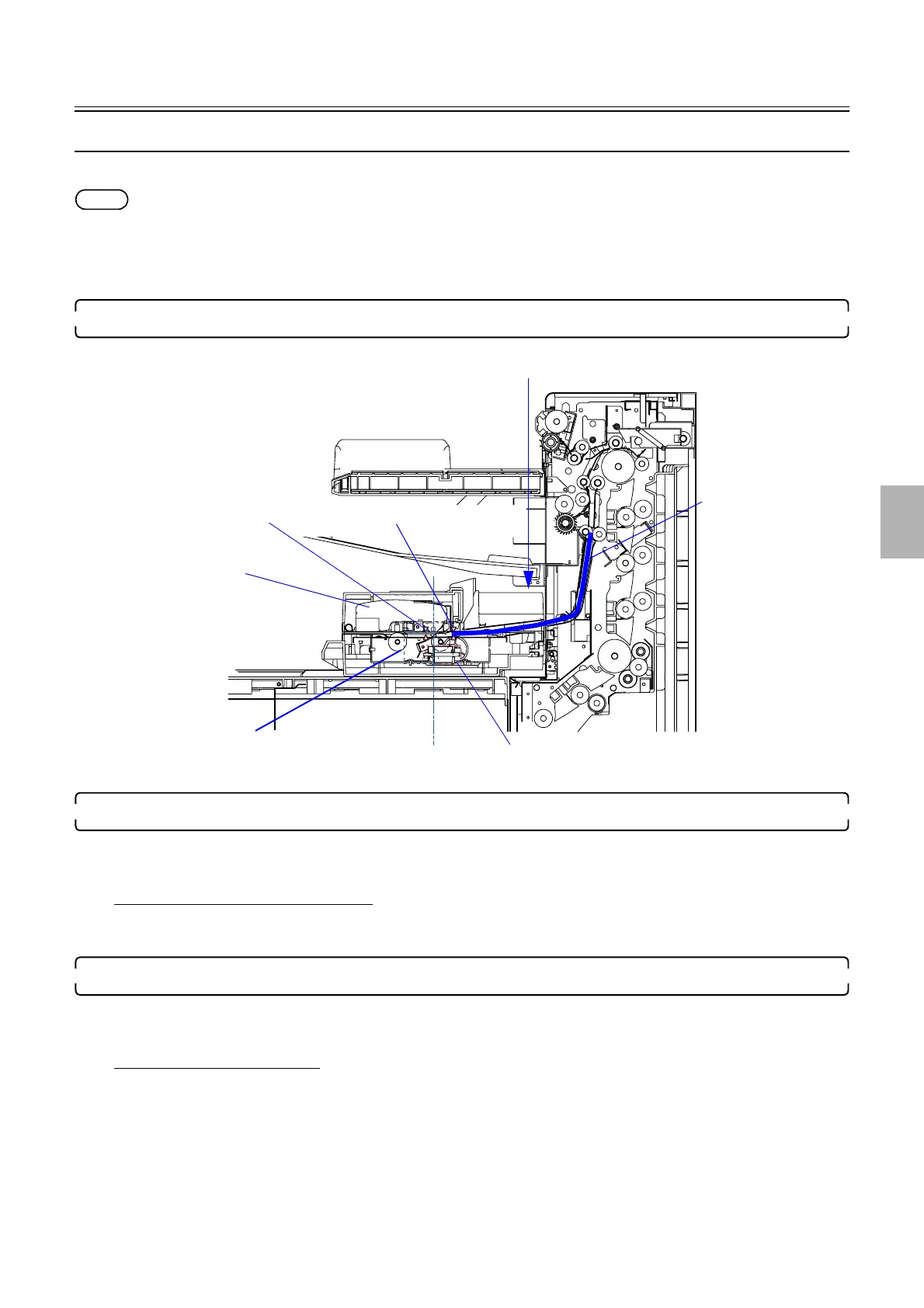

Colorimeter

Paper advance motor

Pressure solenoid

Paper sensor 2

Paper sensor 1

Measuring

Remeasurement inlet

Paper

G085219

Distributed by: minilablaser.com

Loading...

Loading...