4.17.2 Stop After DC Braking

When the operation frequency reaches the set value during deceleration (DC braking

frequency) the inverter stops the motor by supplying DC power to the motor. With a stop

command input, the inverter begins decelerating the motor. When the frequency reaches

the DC braking frequency set at ADV-17, the inverter supplies DC voltage to the motor and

stops it.

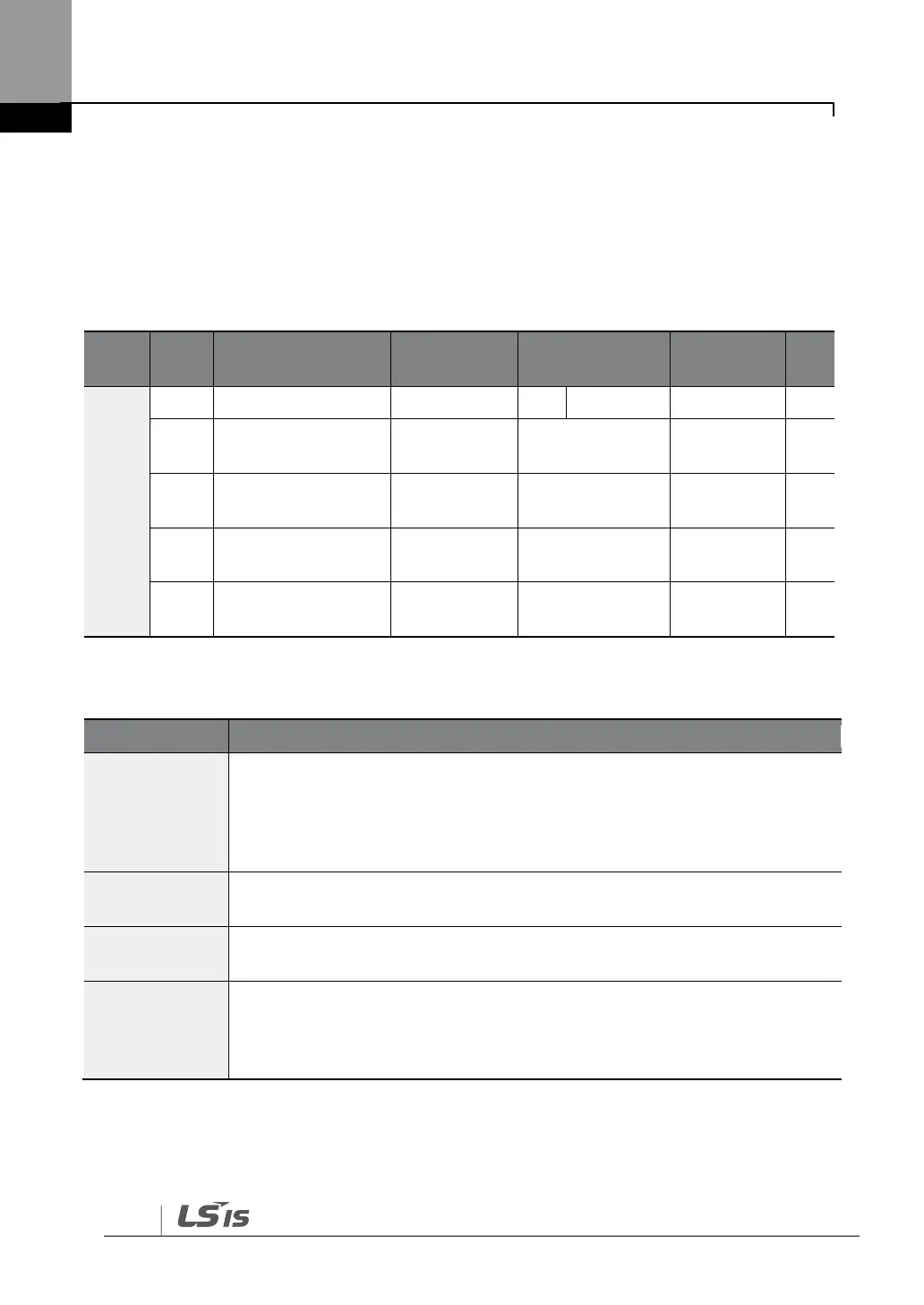

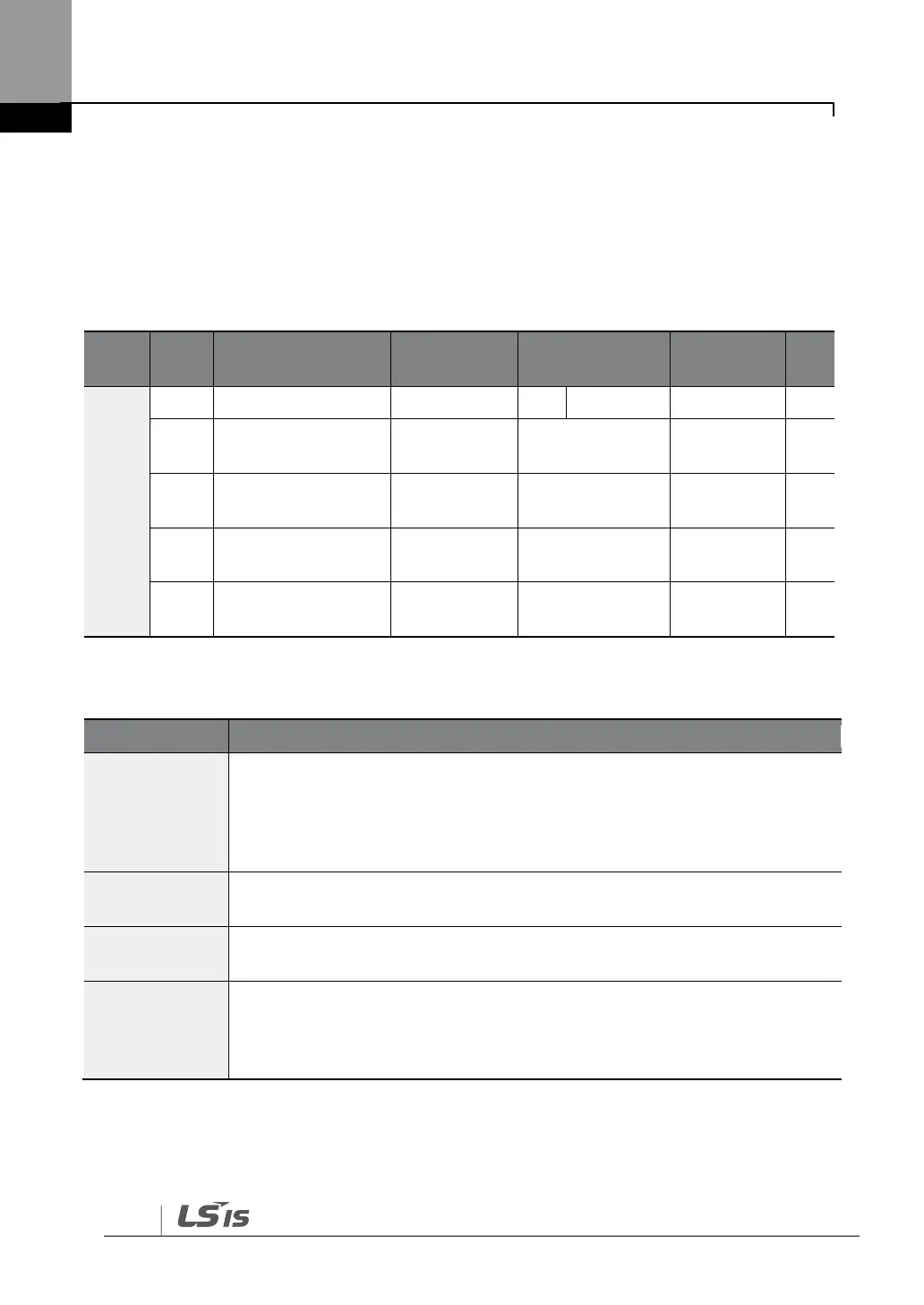

Output block time

before braking

DC Braking After Stop Setting Details

Set the time to block the inverter output before DC braking. If the inertia of

the load is great, or if DC braking frequency (ADV-17) is set too high, a fault

trip may occur due to overcurrent conditions when the inverter supplies DC

voltage to the motor. Prevent overcurrent fault trips by adjusting the output

block time before DC braking.

Set the time duration for the DC voltage supply to the motor.

Set the amount of DC braking to apply. The parameter setting is based on

the rated current of the motor.

Set the frequency to start DC braking. When the frequency is reached, the

inverter starts deceleration. If the dwell frequency is set lower than the DC

braking frequency, dwell operation will not work and DC braking will start

instead.

Loading...

Loading...