214683 418 Revision A

5.6.5 Adjusting Gearbox Drive Chain Tension

The gearbox drive chain tension is factory-set, but tension adjustments are required after the first 50 hours, then

every 500 hours or annually (whichever comes first). The gearbox drive chain, located inside the gearbox, requires

no other regular maintenance.

DANGER

To avoid bodily injury or death from unexpected start-up of machine, always stop engine and remove key

from ignition before leaving operator’s seat for any reason.

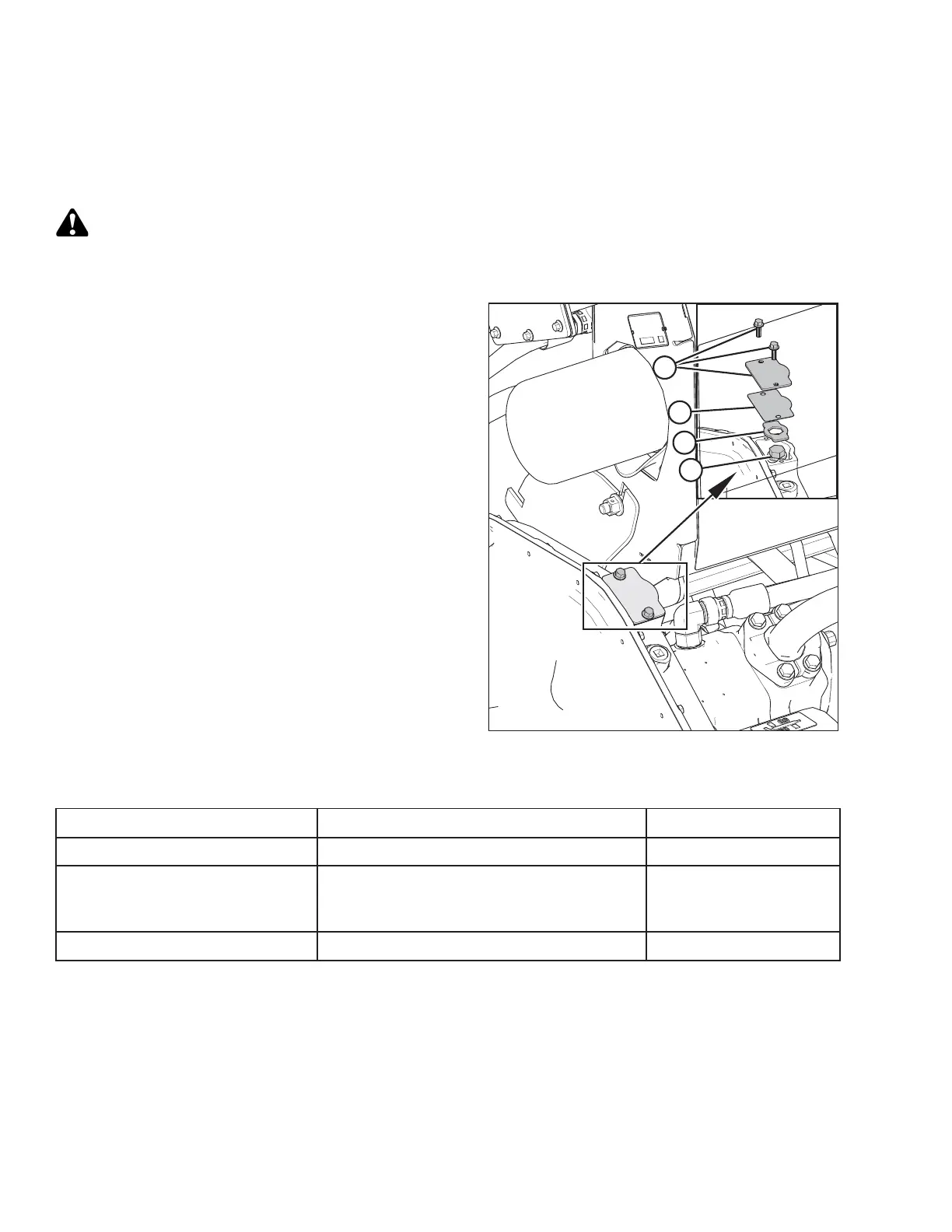

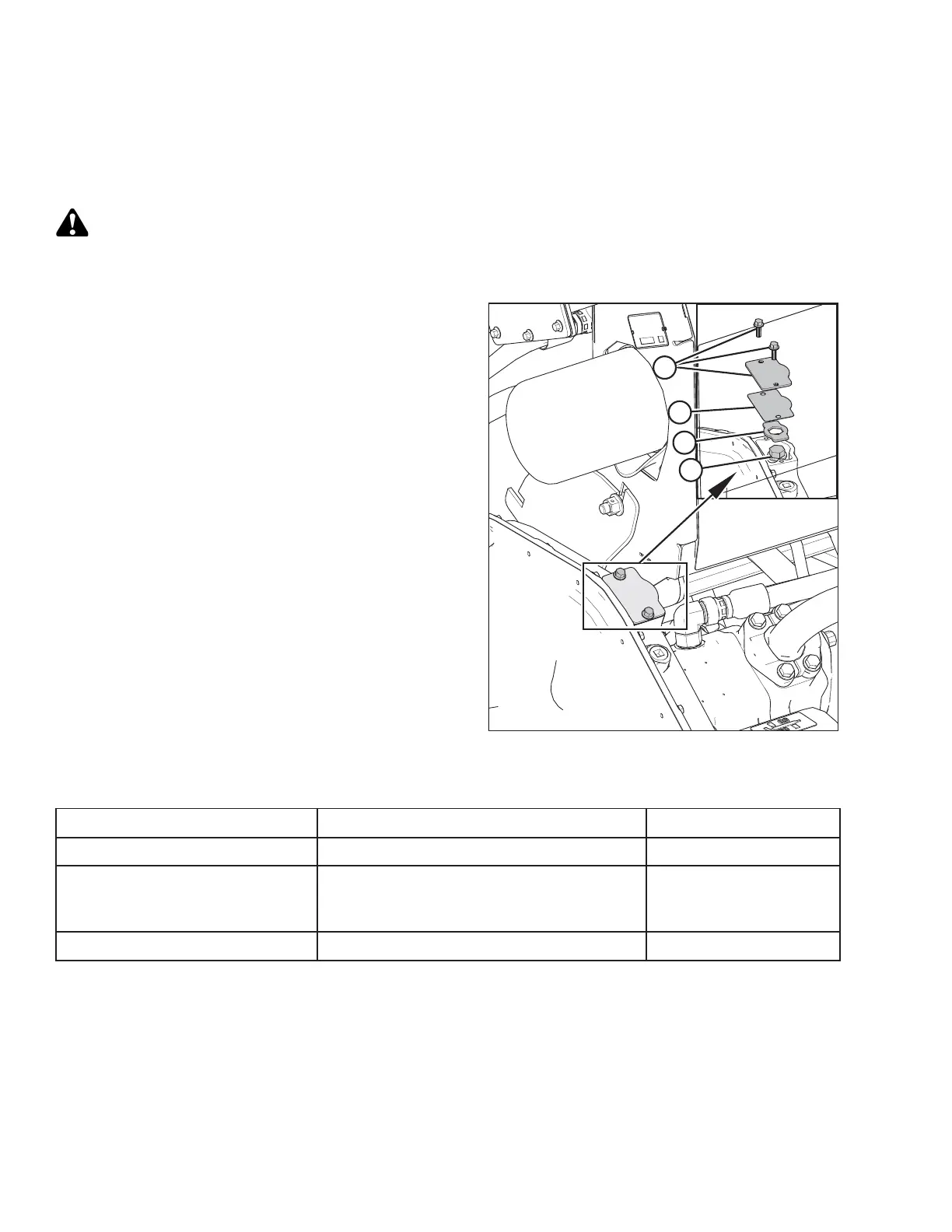

Figure 5.47: Chain Tensioner

1. Lower the header.

2. Shut down the combine, and remove the key from the

ignition.

3. Remove two bolts and the chain adjusting cover (A).

Ensure there is no gasket (B) damage.

4. Remove the retainer plate (C).

5. Tighten bolt (D) to 6.8 Nm (60 lbf∙in).

6. Refer to Table 5.1, page 418 and back off (loosen)

bolt (D) based on your gearbox configuration.

NOTE:

A properly tensioned chain has 10–14 mm (3/8–

9/16 in.) of deflection at its midpoint.

7. Reinstall the retainer plate (C).

8. Reinstall the chain adjusting cover (A) and gasket (B).

Torque hardware to 9.5 Nm (84 lbf∙in).

Table 5.1 Adjusting Bolt Tightness on Configured Gearboxes

Gearbox Configuration Gear Ratios Back Off Amounts

CLAAS 22/38 sprocket ratio, 74 pitch chain 1 turn

Case, New Holland,

and AGCO (Challenger, Gleaner,

Massey Ferguson)

29/38 sprocket ratio, 78 pitch chain

1 turn

John Deere

37/38 sprocket ratio, 80 pitch chain 2-1/2 turn

MAINTENANCE AND SERVICING

Loading...

Loading...