214683 469 Revision A

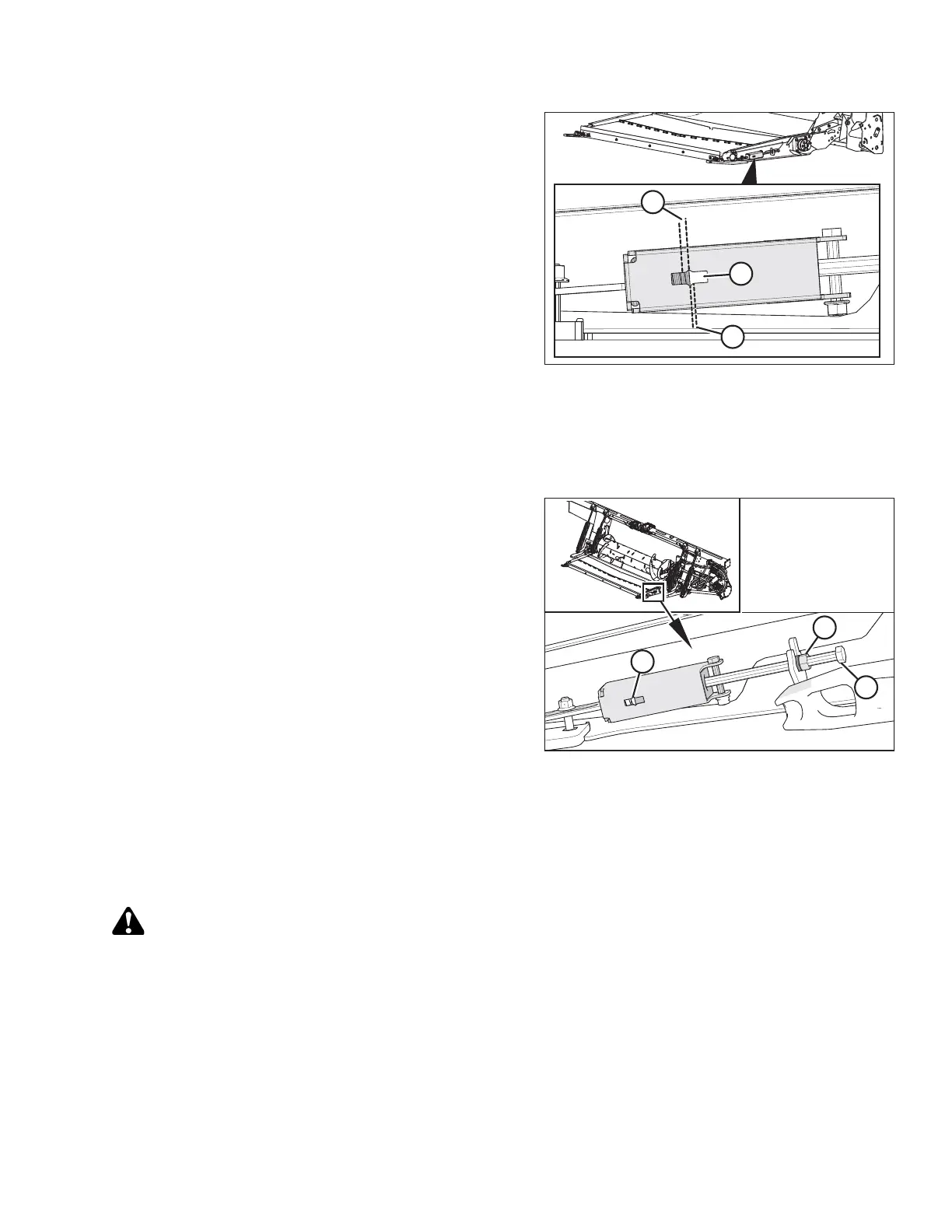

Figure 5.146: Feed Draper Tensioner

NOTE:

The default position of spring retainer (white indicator) is

the center of the spring box window (A); however, the

position of the spring retainer varies with draper tracking

adjustment at the factory.

4. Check the position of white indicator (A). If feed draper

tracks properly and spring retainers on both sides are

positioned within the following dimensions, than no

adjustment is necessary:

• Loosened to 3 mm (1/8 in.) (B) (aft of center in

indicator window [A])

• Tightened to 6 mm (1/4 in.) (C) (forward of center in

indicator window [A])

NOTE:

Left side of float module shown. Right side is

opposite.

5. If adjustment is necessary, proceed to Step 6, page 469

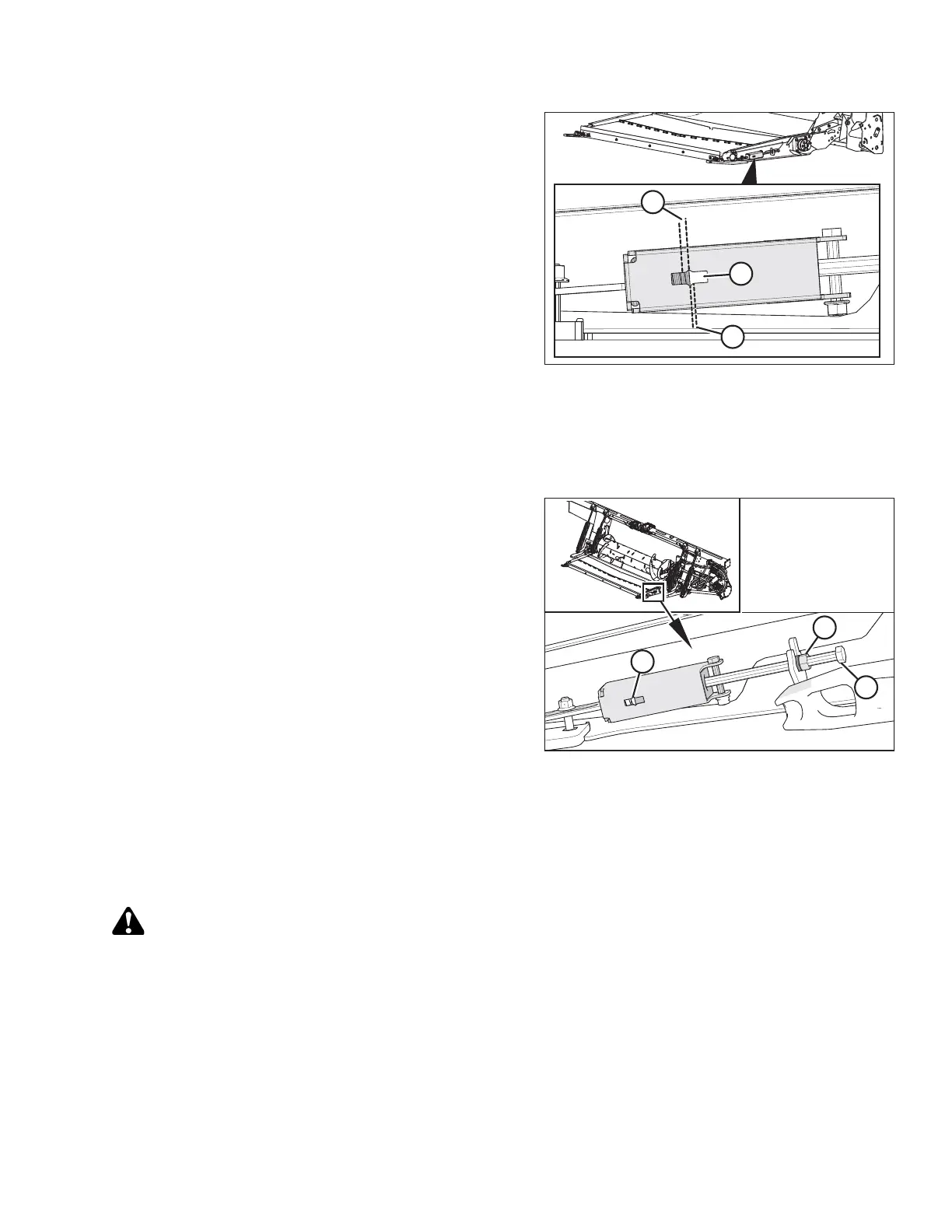

Figure 5.147: Feed Draper Tensioner

6. To adjust feed draper tension, loosen jam nut (A) and

turn bolt (B) clockwise to increase draper tension or

counterclockwise to decrease draper tension.

7. Adjust the draper tension until the white indicator (C) is

within the range described in Step 4, page 469.

IMPORTANT:

To avoid uneven draper tracking, adjust both sides

equally.

8. Tighten jam nut (A).

5.10.3 Feed Draper Drive Roller

This roller is powered and moves the draper on the float module, conveying crop to the auger.

Removing Feed Draper Drive Roller

DANGER

To avoid bodily injury or death from unexpected start-up or fall of a raised machine, always stop engine

and remove key before leaving the operator’s seat, and always engage safety props before going under

the machine for any reason.

1. Raise the header and reel to full height, strop the engine, and remove the key from the ignition.

2. Engage reel safety props and header safety props.

MAINTENANCE AND SERVICING

Loading...

Loading...