Pathway Technical Reference Manual

Proprietary 172 of 190

22. Appendix J – Preventive and Periodical

Maintenance

This chapter describes the preventative and periodical maintenance procedures required in

order to maintain good system performance and safety of use.

22.1 Summary Maintenance Table

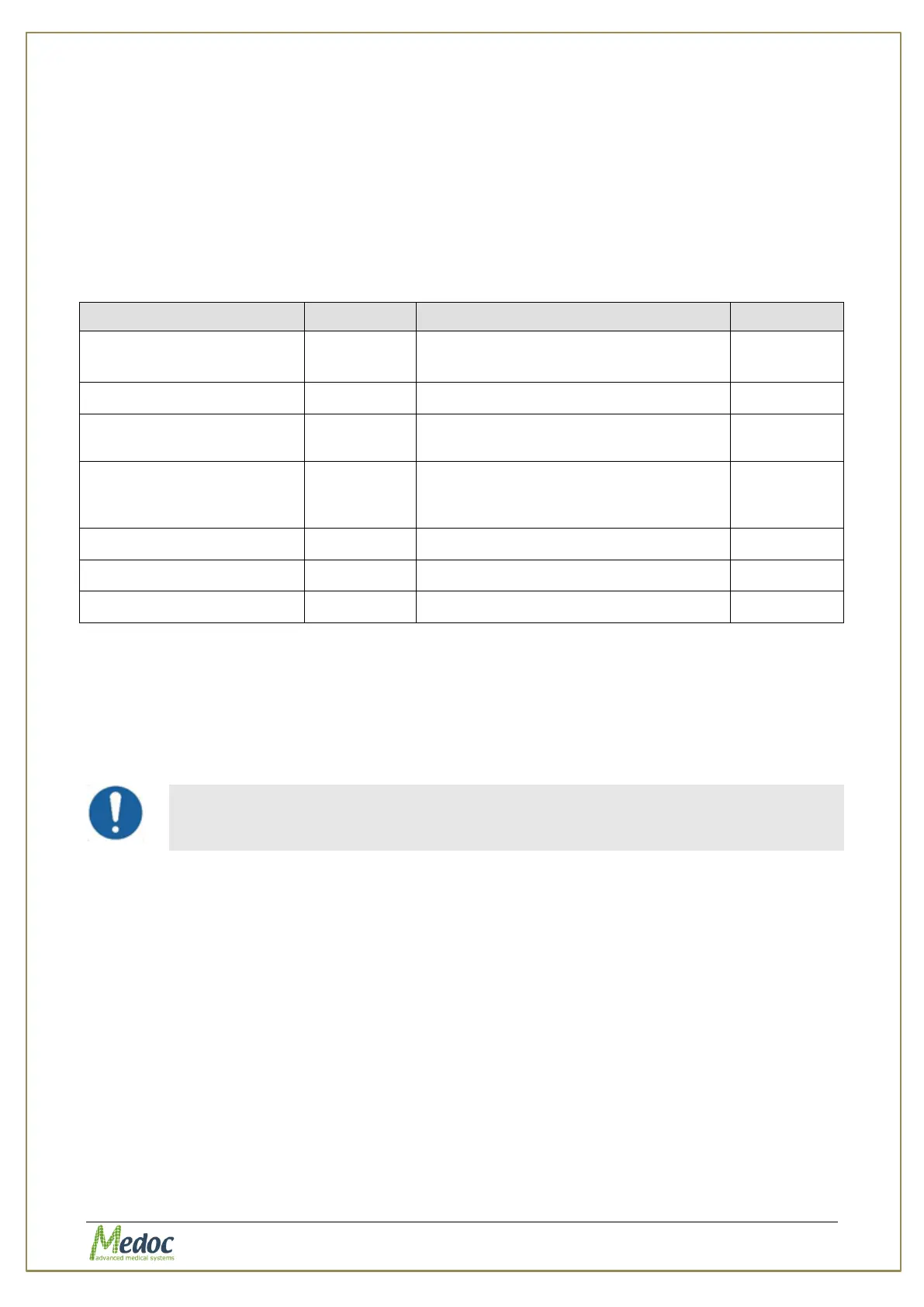

The following table summarizes the required maintenance procedures.

Table 41: Summarizing Maintenance Table

Depending on usage. Perform once a

month if system is not used often

Only if system is not being used

regularly.

Requires a calibration kit. Some

study protocols may require

Thermode calibration more often

22.2 Daily Preventative Maintenance Operations

22.2.1 Visual Check

The visual check is important to ensure that all system components are intact and properly

connected before using the system.

The Visual check is required in order to make sure that there is no physical

damage to system components, particularly to the Thermodes.

1. Check all accessories and Thermodes visually.

1.1. Check that the accessory connectors are intact.

1.2. Check that the all the accessories’ bodies are intact.

1.3. Check that there is no visible damage to the Thermode heads. Check especially that

the Kapton® cover of the CHEP Thermode is intact and not peeled.

2. Make sure both Thermodes are properly connected the PATHWAY system. If your license

only includes one Thermode type (CHEPS or ATS), make sure to connect a bypass water

tube in place of the water connectors of the missing Thermode.

3. Connect all available Pathway accessories (Response Unit, Panic Button and etc.)

4. Make sure coolant level is between the minimum and maximum level (add coolant if

required, refer to section 19 for instructions).

22.2.2 Flow Rate Check

The flow rate is important to ensure the Thermodes get enough circulation of coolant for safety

and good performance. The required flow rate is approx. 37 LPH (indicator should be center

Loading...

Loading...