CAUTION

Do not use heavy equipment, such as a hammer, to install the SeVG Plus

actuator as it may damage the actuator housing and lead to failure of the

actuator.

Do not apply force to the motor rod. Hold the motor rod end by the ats and

use a proper key during tightening of the valve pin holder to the motor rod

end thread. Permanent damage to the anti rotation mechanism will occur if

the proper tool is not used. See Figure 12-7.

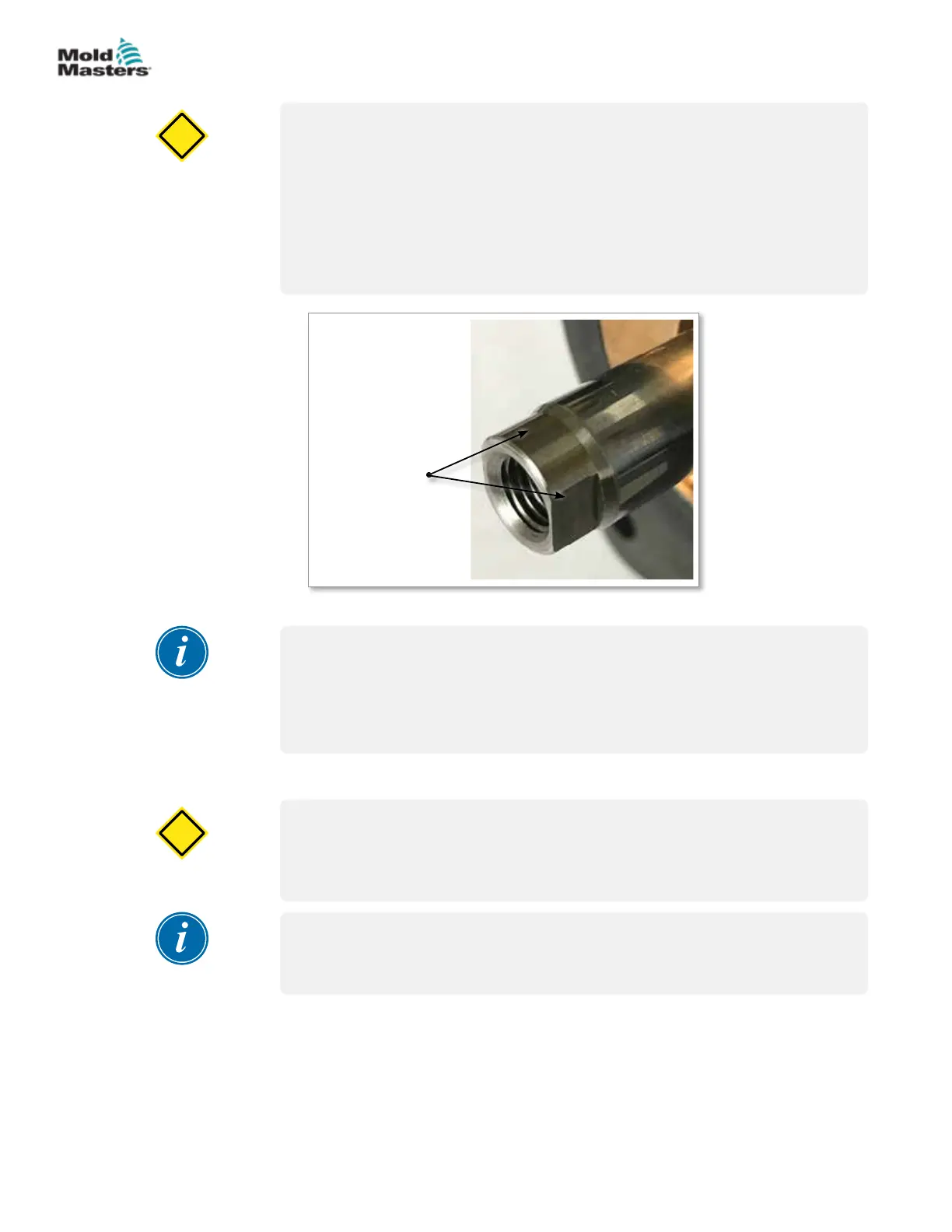

CAUTION

Hold the motor

rod by the

ats.

Figure 12-7 Motor rod ats

IMPORTANT

If the Hot Runner system contains plastic, heat the system to processing

temperature before the assembly is placed and see “Warning - hot

surfaces” on page 12-6.

Make sure that the cooling system is also connected.

12.7.1 Attach the Water Lines (Cooled Models Only)

CAUTION

Ensure that excess force is not exerted on the interface between the tting

and the aluminum motor casing. Choose the most suitable torque method

for the assembly practice. See section 12.7.1.1 and section 12.7.1.2.

CAUTION

NOTE

The timing of this step is system dependent and it is the responsibility of the

integrator.

12.7.1.1 Use a Torque Wrench

• torque should not exceed 22 ft. lb. for solid pipe attachment or for swivel nut /

hose connections

12.7.1.2 Use Flats From Wrench Resistance Method

• do not exceed 2 ats for tube connections to the tting

• do not exceed 1.5 ats for swivel nut / hose connections

Assembly and Installation - continued

12-7SEVG PLUS ACTUATOR

Hot Runner User Manual

© 2020 Mold-Masters (2007) Limited. All Rights Reserved.

Loading...

Loading...