Section 4 - Preparation

WARNING

Ensure that you have fully read “Section 3 - Safety” before unpacking,

cleaning or assembling parts of the Hot Runner system.

The following section is a step-by-step guide to prepare your Mold-Masters

system for use.

4.1 Tools Required

Depending on the size and complexity of your Hot Runner system, you will

require most of the tools and materials listed below.

• Allen keys: Depending on system, set of metric or imperial size keys

to use 4, 5, 6, 8 and 10 mm (0.16, 0.20, 0.24, 0.31 and 0.39 in.) on

cap screws

• Nickel based anti-seize compound: to prevent oxidation of screw

threads that could cause screws to seize with high temperatures

• Solvents (denatured alcohol): for removal of rust inhibitors

• Calibrated torque wrench: for consistent screw pressure throughout

the system

• Pliers: for general assembly work

• Circlip pliers: to remove and install circlip in valve systems

• Micrometer: 0-150 mm (0-5.9 in.) to check system part and plate

thickness

• Depth micrometer: to check bore depths

• Slot head screw driver: used in installing thermocouples and ground

wires

• Slot head screw driver (small): used in fastening electrical wires to

connectors

• Crimping tool: for fastening connector pins when necessary

• Wire strippers: for preparing wires

• Utility knife: for cutting tape, wires etc.

• Glass tape: for grouping wires into zones

• Dye spotting blue compound: for checking face contact

• Sockets

• Lapping compound for valve gate systems

• Plastic face hammer

• Proper actuator installation / extraction tools

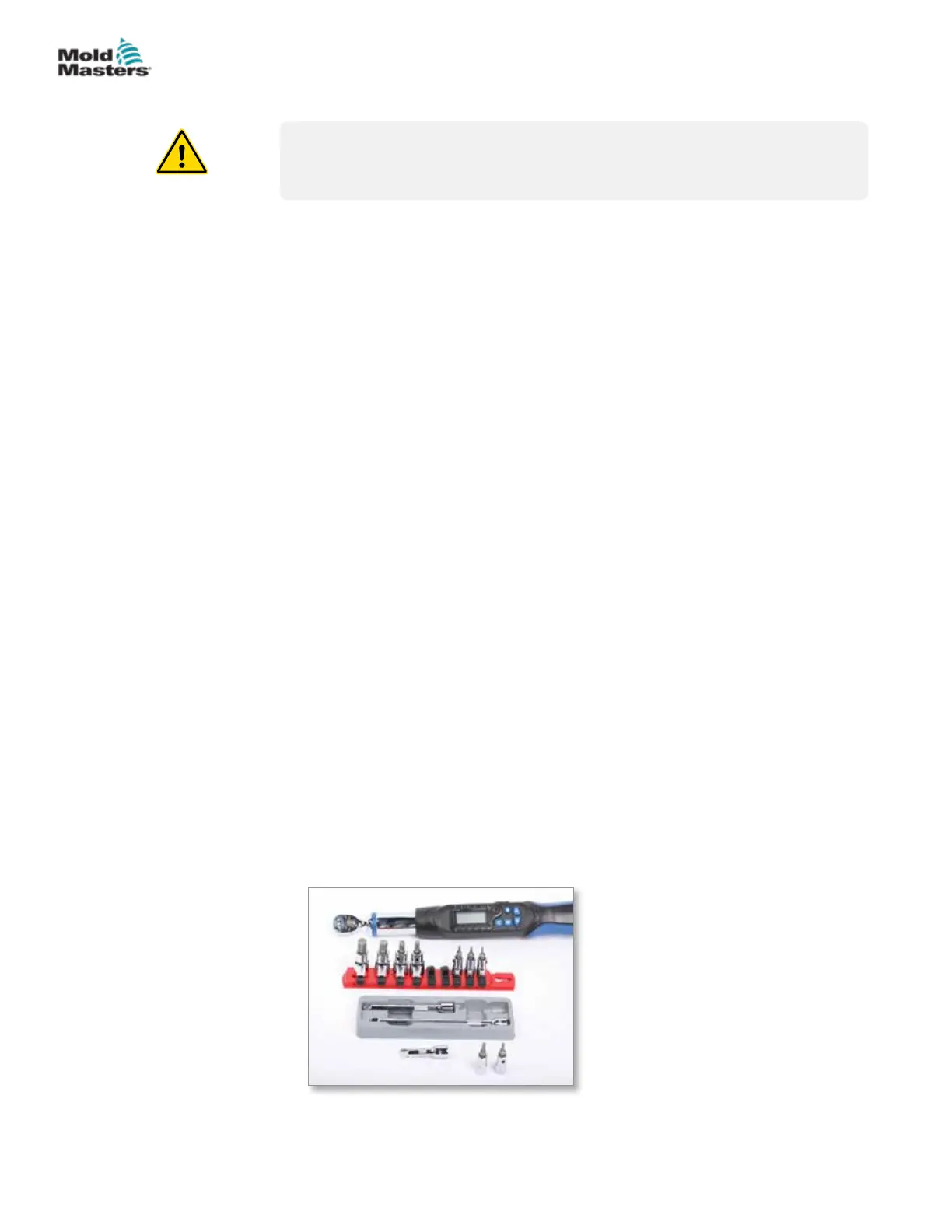

Figure 4-1 Toolkit required

4-1PREPARATION

Hot Runner User Manual

© 2020 Mold-Masters (2007) Limited. All Rights Reserved.

Loading...

Loading...