5.21 Inlet Components Installation

CAUTION

For all inlet components it is important that the mold locating ring is

touching the inlet component just enough for sealing the area. This should

be double checked with the system drawings.

CAUTION

The following procedures refer to dierent system congurations. Refer to

your parts list and General Assembly drawings to determine your system

type.

5.21.1 Back Plate Installation

1. Check the machine nozzle radius.

2. Check the seating on the bottom face of the back plate and manifold.

3. Install the back plate onto the manifold.

4. Install M8 mounting screws through the back plate to the manifold using

anti-seize compound on threads.

5. Torque screws to value indicated on the General Assembly drawing in a

cross pattern, in 7 Nm (5 lbf-ft) increments.

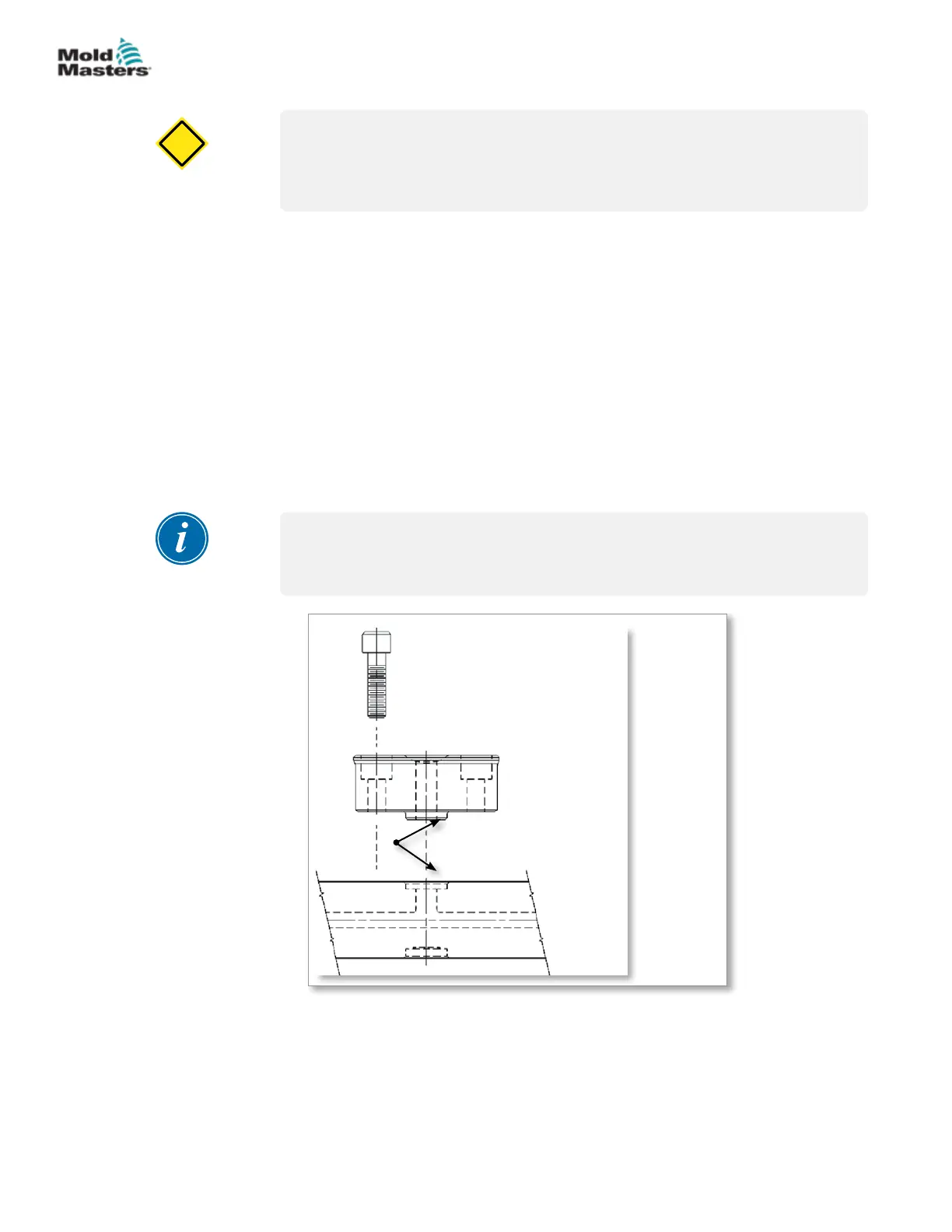

NOTE

The machine nozzle bore should be no less than 1.0 mm (0.040 in.) smaller

than the back plate bore and no larger than the back plate bore.

1

2

3

4

5

1. Mounting screw

2. Nozzle radius

3. Back plate

4. Manifold

5. Bottom face

Figure 5-39 Back plate installation

5-46

© 2020 Mold-Masters (2007) Limited. All Rights Reserved.

ASSEMBLY

Hot Runner User Manual

Loading...

Loading...