5.17.5 Valve Disk - Final Grinding Required

These valve disks are supplied with stock allowance (oversized in height),

and they require grinding to the nal dimension specied on the system

General Assembly drawing.

1. Grind the valve disk on top side only.

2. Remove sharp corners after grinding and clean the valve disk, especially

inside the valve pin bore.

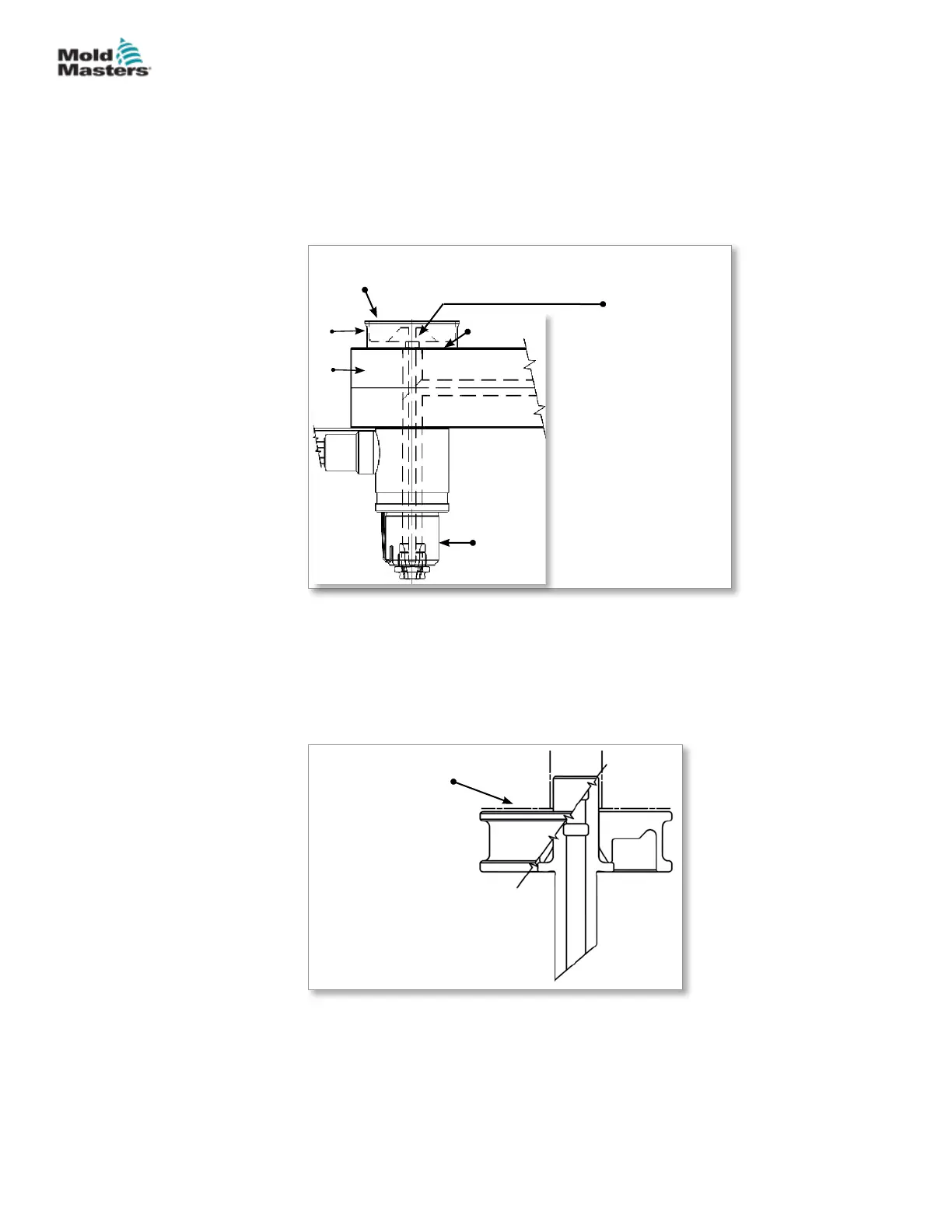

1

2

4

3

Clean bore after

grinding

Ensure correct air gap as per General

Assembly drawing

1. Spring dowel

2. Nozzle

3. Manifold plate

4. Valve disk

Figure 5-32 Manifold to nozzle mounting

3. Install the manifold to the nozzle.

4. For 1-piece valve disk - Install the valve disk in appropriate orientation.

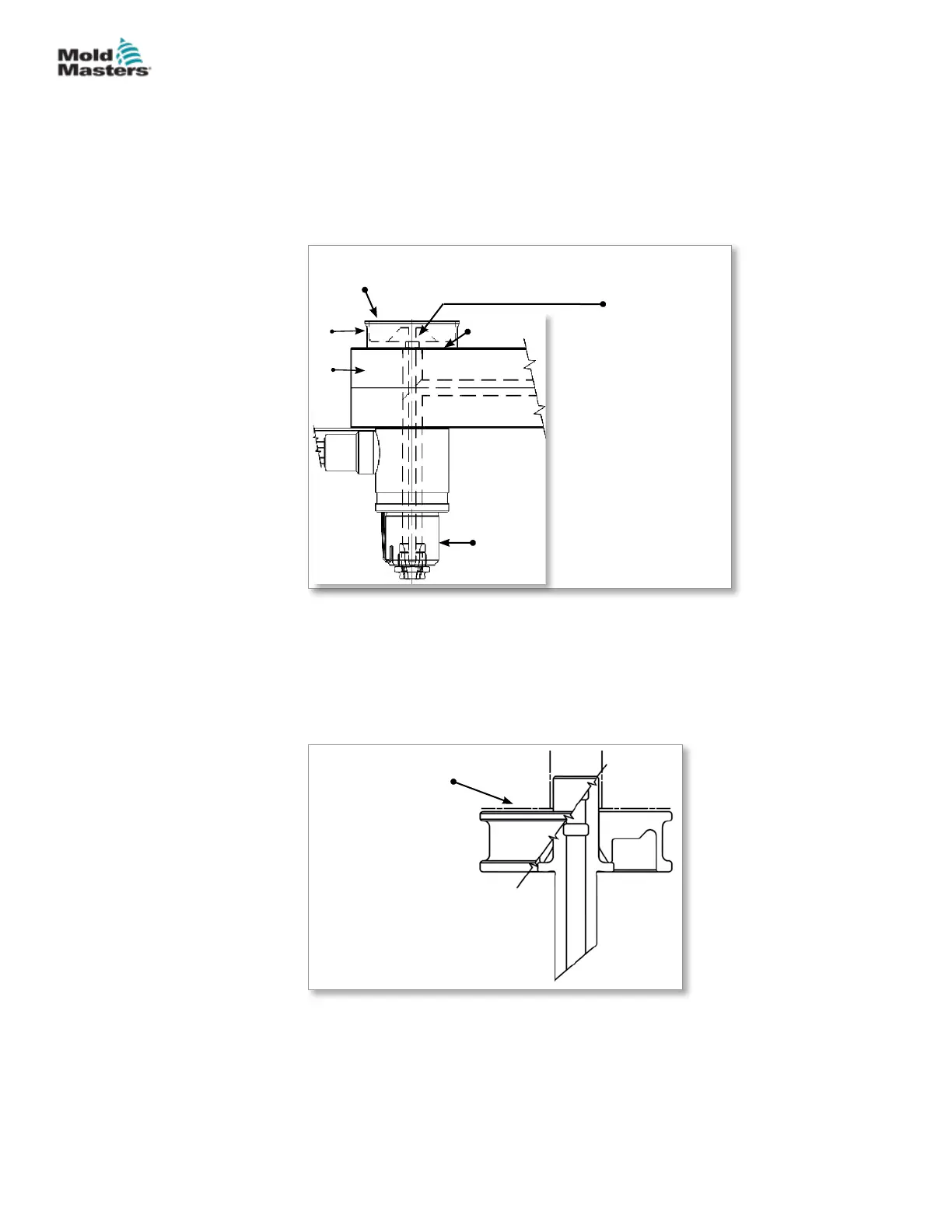

For 2-piece valve disk - Insert valve stem into the manifold in appropriate

orientation. Slide valve disk ange over the stem. See Figure 5-33.

Ensure correct air

gap as per General

Assembly drawing

1

2

1. Valve disk ange

2. Valve disk stem

Figure 5-33 2-piece valve disk

5. Ensure correct air gap between the valve disk and the top plate as

specied in the General Assembly drawing.

6. For information on removal, refer to “15.1 Valve Disk Removal” on page

15-1.

5-40

© 2020 Mold-Masters (2007) Limited. All Rights Reserved.

ASSEMBLY

Hot Runner User Manual

Loading...

Loading...