0 60 120 180 240 300 360

0

50

100

150

200

250

300

350

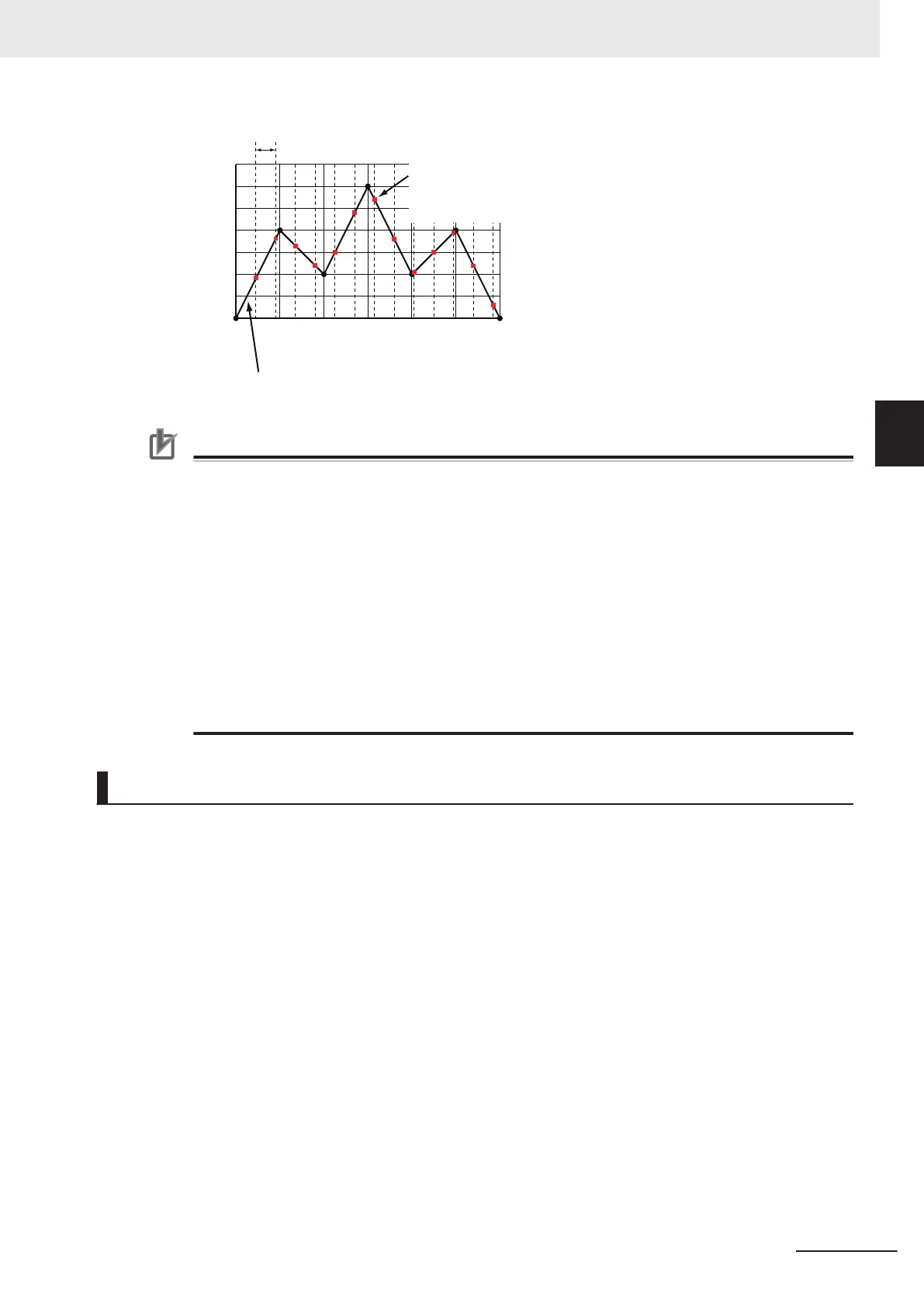

The phase is calculated from the master

axis position for each cycle. The linear

interpolation of cam data is used to

calculate displacements from the phases.

(These are the red dots on the line.)

Command position during electronic cam operation

1 cycle

Linearl

y interpolate between cam data (black dots on the line).

Phase

Displace-

ment

Precautions for Correct Use

• When executed, this instruction checks if the phases are in ascending order. If they are not in

ascending order, an error occurs.

When you change cam data, execute the MC_SetCamTableProperty (Set Cam Table Proper-

ties) instruction to make sure that the phases are in ascending order.

Make sure that the phases will be in ascending order before you change the phases during a

cam motion. The cam motion may stop if the phases are not in ascending order.

• Cam data variables are global variables. You can therefore access or change the values of

cam data variables from more than one task. If you change the values of cam data variables

from more than one task, program the changes so that there is no competition in writing the

value from more than one task.

• If you use exclusive control of global variables between tasks for a cam data variable, do not

use the cam data variable for motion control instructions while exclusive control is in effect for

the cam data variable. An Incorrect Cam Table Specification error (error code: 5439 hex) will

occur.

Instruction Details

This section describes the instruction in detail.

Instruction Execution Condition

You can execute this instruction while the master axis is stopped, during position control, velocity con-

trol, or synchronized control.

For details on the slave axis, refer to Re-execution of Motion Control Instructions on page 3-199 and

Multi-execution of Motion Control Instructions on page 3-6.

Software Limits

If the slave axis exceeds the software limit during cam operation, an error occurs.

Cam Data Variables

A cam data variable is declared as an array of cam data structures. The type declaration for the cam

data structure is shown below.

3 Axis Command Instructions

3-179

NY-series Motion Control Instructions Reference Manual (W561)

MC_CamIn

3

Function

Loading...

Loading...