SERVICE CALL 26 July 2002

4-6

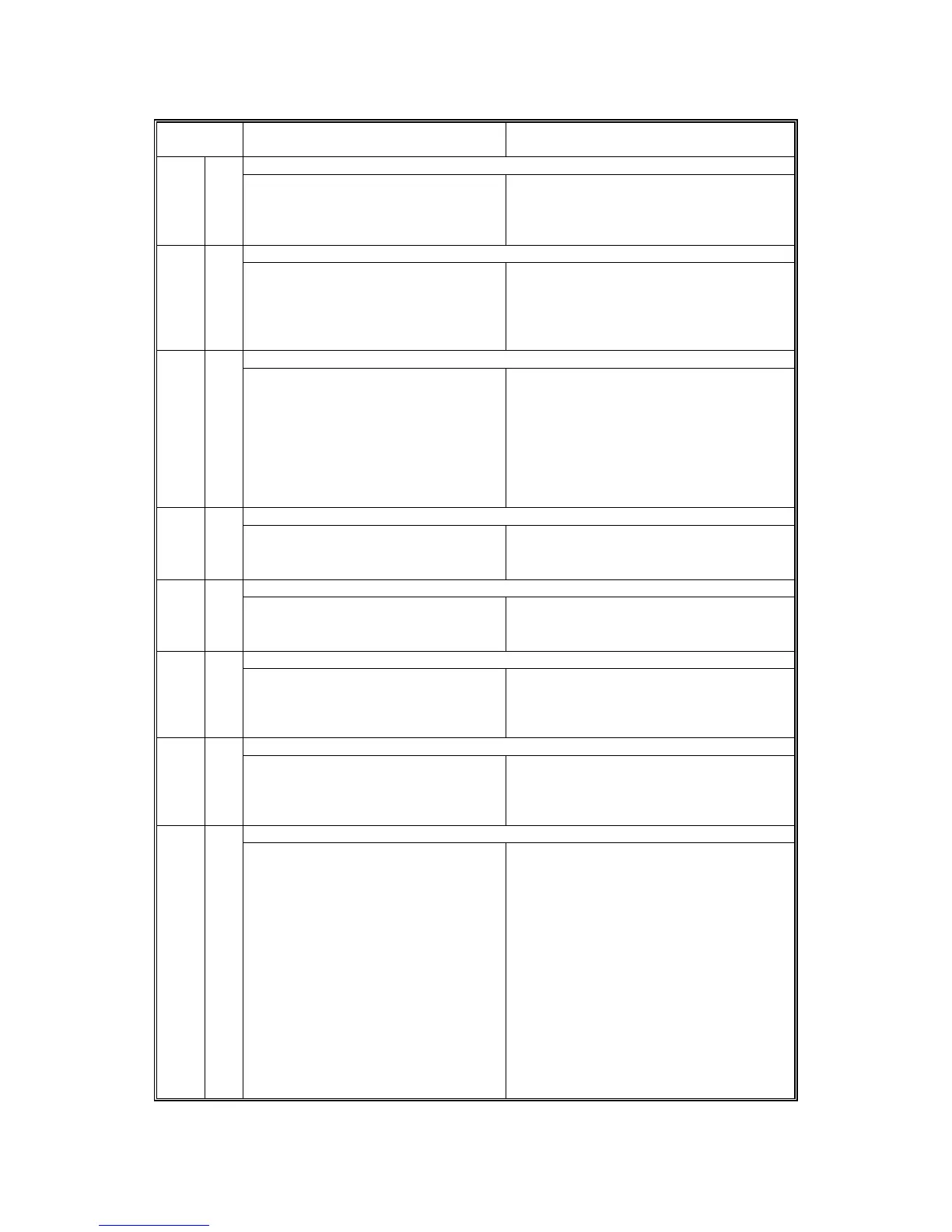

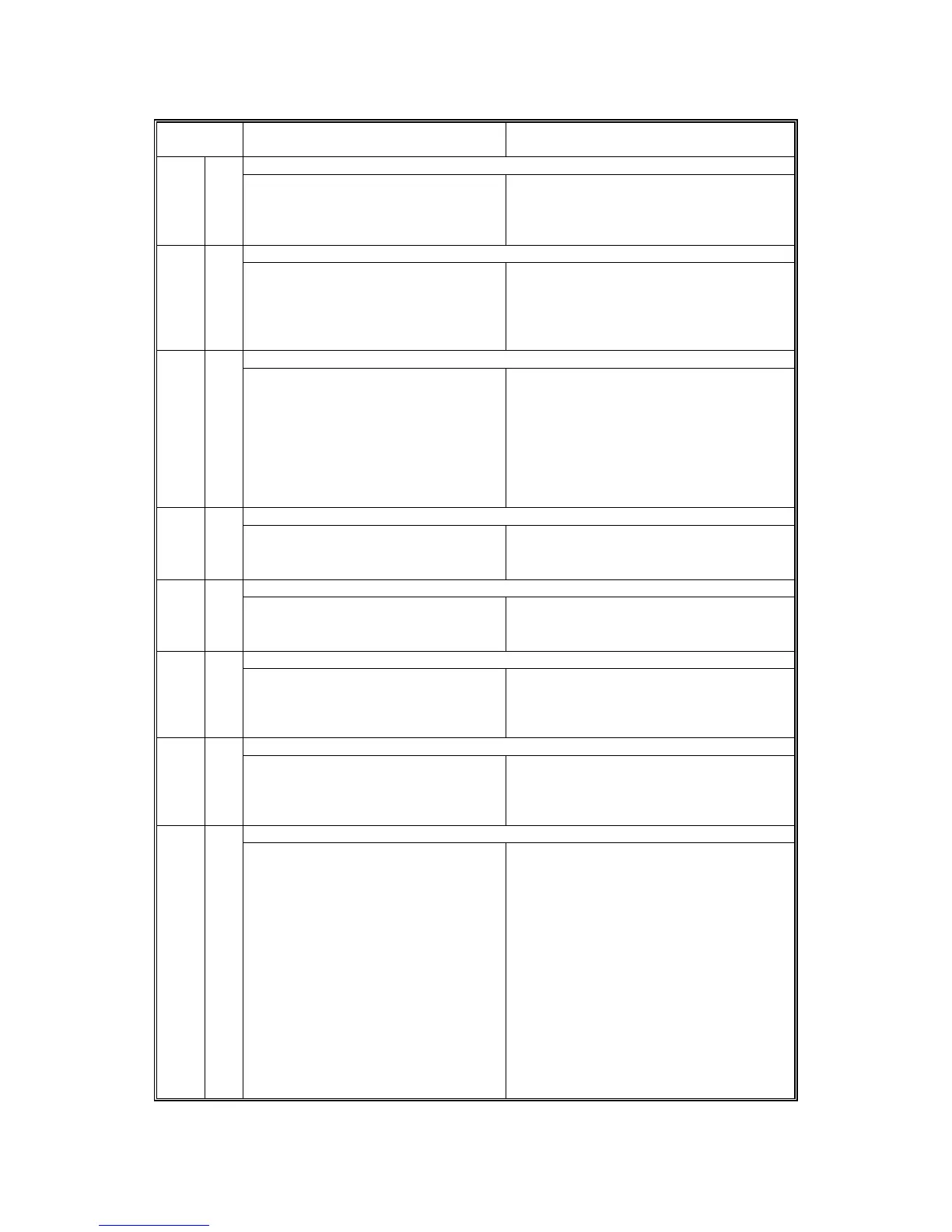

No.

Definition

Symptom Possible Cause

Discharge plate error 421

During discharging, the leakage

detection signal is low for 60

milliseconds.

• Short circuit in the discharge plate

• Defective high voltage supply board

• Defective harness (BICU - high voltage

supply board)

Transfer belt cleaning error 430 D

• Cleaning is operating at the

maximum PWM duty value for 60

milliseconds.

• Short circuit in the transfer belt cleaning

unit

• Defective high voltage supply board

• Defective harness (BICU - high voltage

supply board)

Main motor error 440 D

• The main motor starts or changes

speed. → The lock signal does not

continue for 1 second within 3

seconds.

• The main motor starts. → The lock

signal is detected and operation

proceeds normally. → The lock

signal is interrupted for 1 second.

• Defective main motor

• Too much load of the main motor drive

Temperature sensor error 460 D

The output is 4.5 V (or higher) or 0.3

V (or lower) for 12 seconds.

• Defective temp./ humidity sensor

• Defective circuit

• Defective connector

Humidity sensor error 461 D

The output is 4.5 V (or higher) or 0.3

V (or lower) for 12 seconds.

• Defective temp./ humidity sensor

• Defective circuit

• Defective connector

ID sensor error 480 D

The ID sensor is being calibrated

(process control, step 1) → While the

LED is off, the output voltage is 0.5 V

or lower.

• Defective ID sensor

• Defective connector

Transfer belt mark detection error 481 D

• The main motor is operating; and

the lock signal is detected. → The

belt mark sensor signal does not

change for 120 milliseconds.

• Defective main motor

• Image transfer belt out of position

• Belt mark blurred or absent

3rd tray error 503 B

• The tray lift motor turns on. → The

top of the paper stack is not

detected for 18 seconds.

• The tray is set. → The top of the

paper stack is detected. → The

bottom plate is lowered. → The

stack detection is not cleared within

7 seconds. → These steps are

repeated 4 times.

• Defective paper height sensor

• Defective tray lift motor

Loading...

Loading...