26 July 2002 PROCESS CONTROL

6-17

Detailed

Descriptions

Event Condition Steps

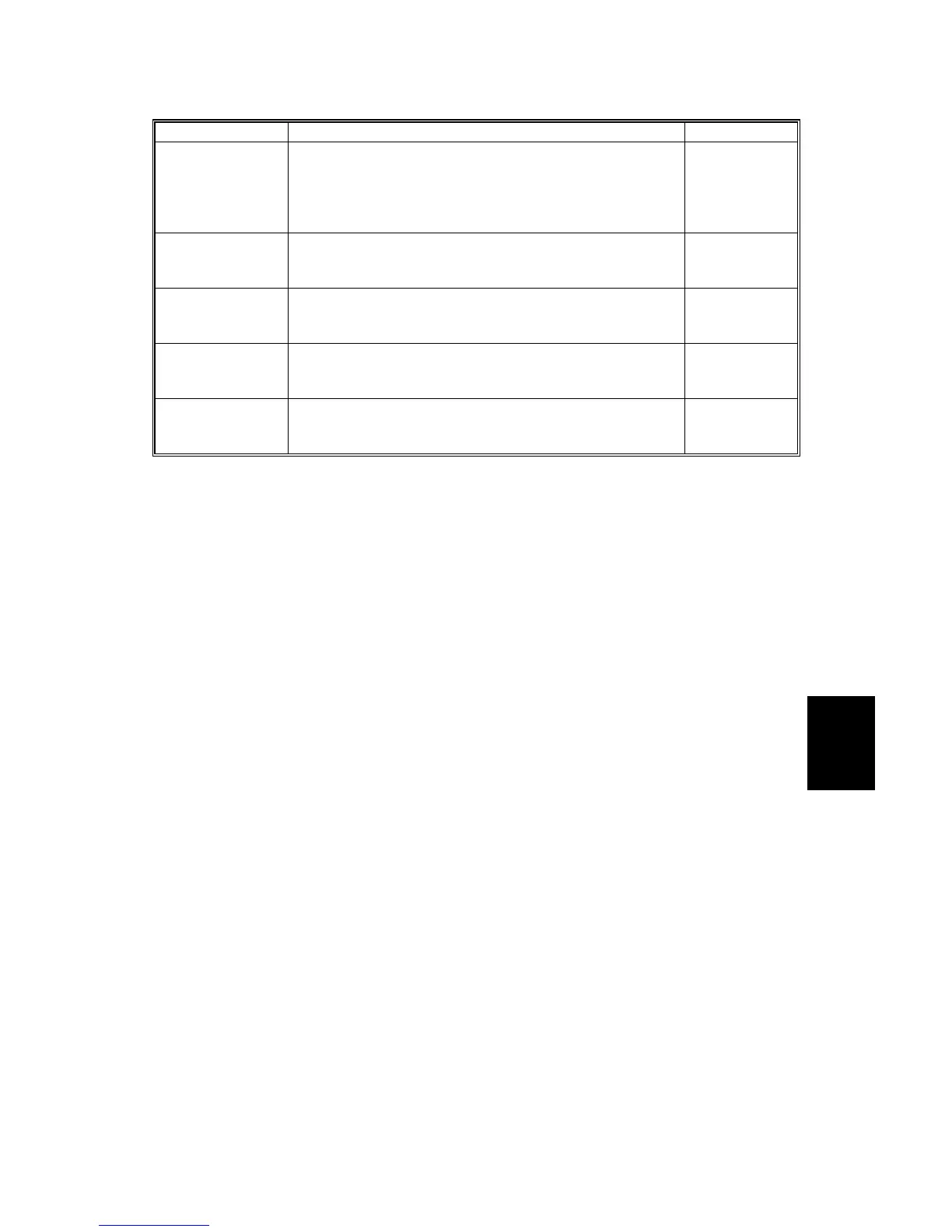

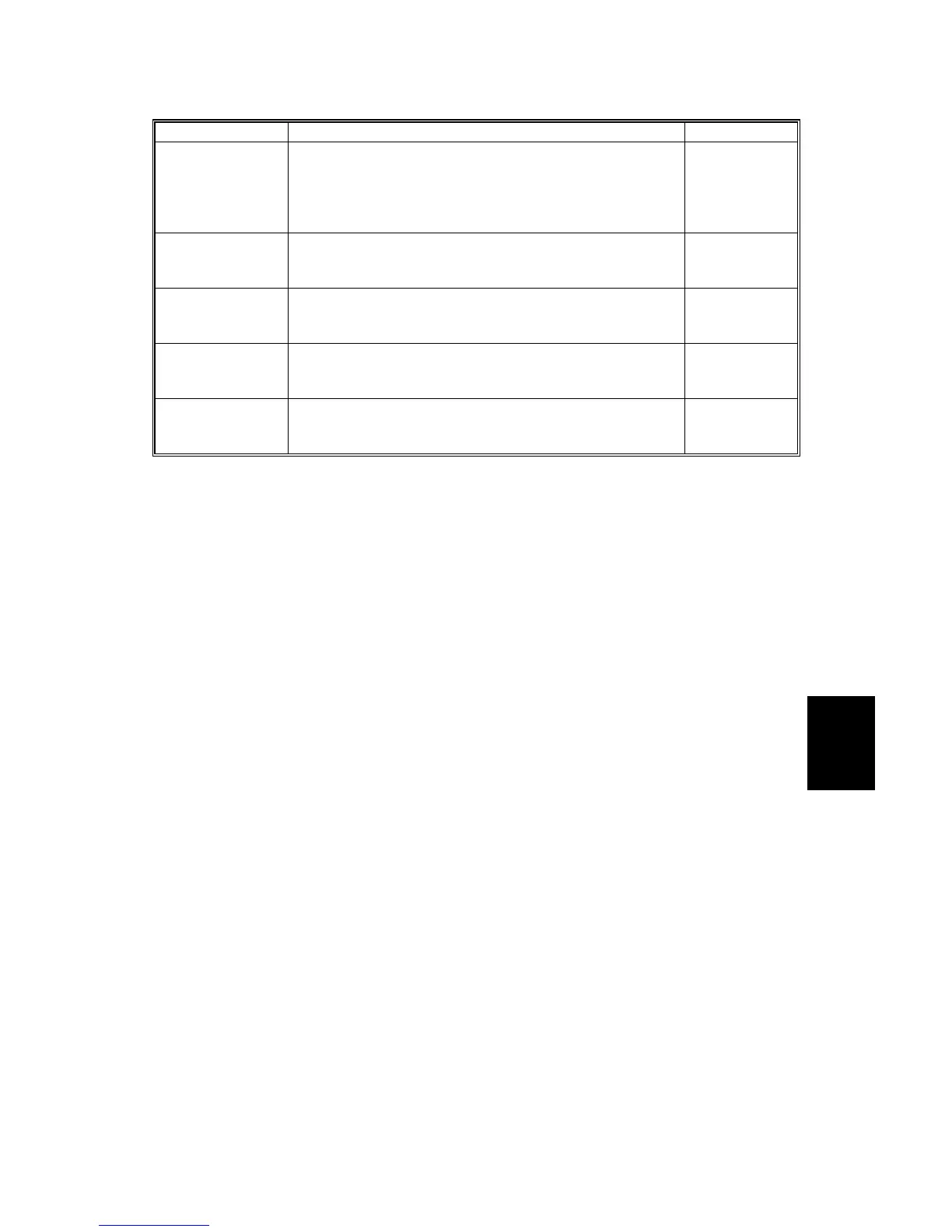

K toner cartridge

or K development

unit replacement

This is done after clearing the K toner near-end state

(i.e., when a new K development unit is added). The

machine idles and when the development roller stops for

10 seconds, indicating that idling is over, process control

occurs.

➀, ➂, ➃, !

Color

development unit

replacement

After the color toner end or near-end state is reset, the

machine idles to transfer color toner to the development

unit. After idling, process control occurs.

➀ → ➅

Color toner

cartridge

replacement

After the color toner end or near-end state is reset, the

machine idles to transfer color toner to the development

unit. After idling, process control occurs.

➀, ➃, ➄, ➅

24 hours after

previous process

control

Same as ‘power on’ process control

➀, ➃, ➄, ➅

PCU replacement After the PCU counter is reset, it is lubricated (new OPC

belt lubricant application mode). Then process control

occurs.

➀ → ➅

Supplementary Information on Process Control

The following is a brief explanation of process control. This is for your reference. If

the information is helpful for understanding the machine in the field, read the

following explanation.

Step 1. ID Sensor Calibration

This calibration compensates for changes in the condition of the OPC belt or the ID

sensor. The ID sensor detects the light reflected from the bare OPC belt. The LED

current is adjusted until the sensor output is correct. The LED current for the color

toner detection circuit is adjusted based on the adjustment made for the black toner

detection circuit.

Step 2. Initializing Color Development Bias

For each color, the machine makes a solid patch (20x25) of toner on the OPC belt.

The ID sensor detects the density of the patch. The laser power for the patch of

toner is constant at about 210/255. Each color is calibrated separately (this step

has three stages - one for each color). M/A must be the following for areas of

maximum image density: 0.65 mg/cm

2

, Range:0.40 to 0.90 mg/cm

2

. If the detected

M/A is different from the target M/A, the development bias is adjusted.

Colour development bias initialisation is not always done. This is to reduce the

amount of time taken for process control. Also, in step 4, the current colour

development bias values are fine-tuned to correct for any changes in the machine

or temperature/humidity since the last full process control.

This step always has to be done when installing a new development unit. The toner

amount carried by a development roller varies with each unit. (The toner amount

used for a certain development bias is not the same.) Black development bias

initialisation (step 3) has to be done more often, because tests have shown that

process control errors occur more often if this is not done.

Loading...

Loading...