26 July 2002 SERVICE PROGRAM MODE

5-21

Service

Tables

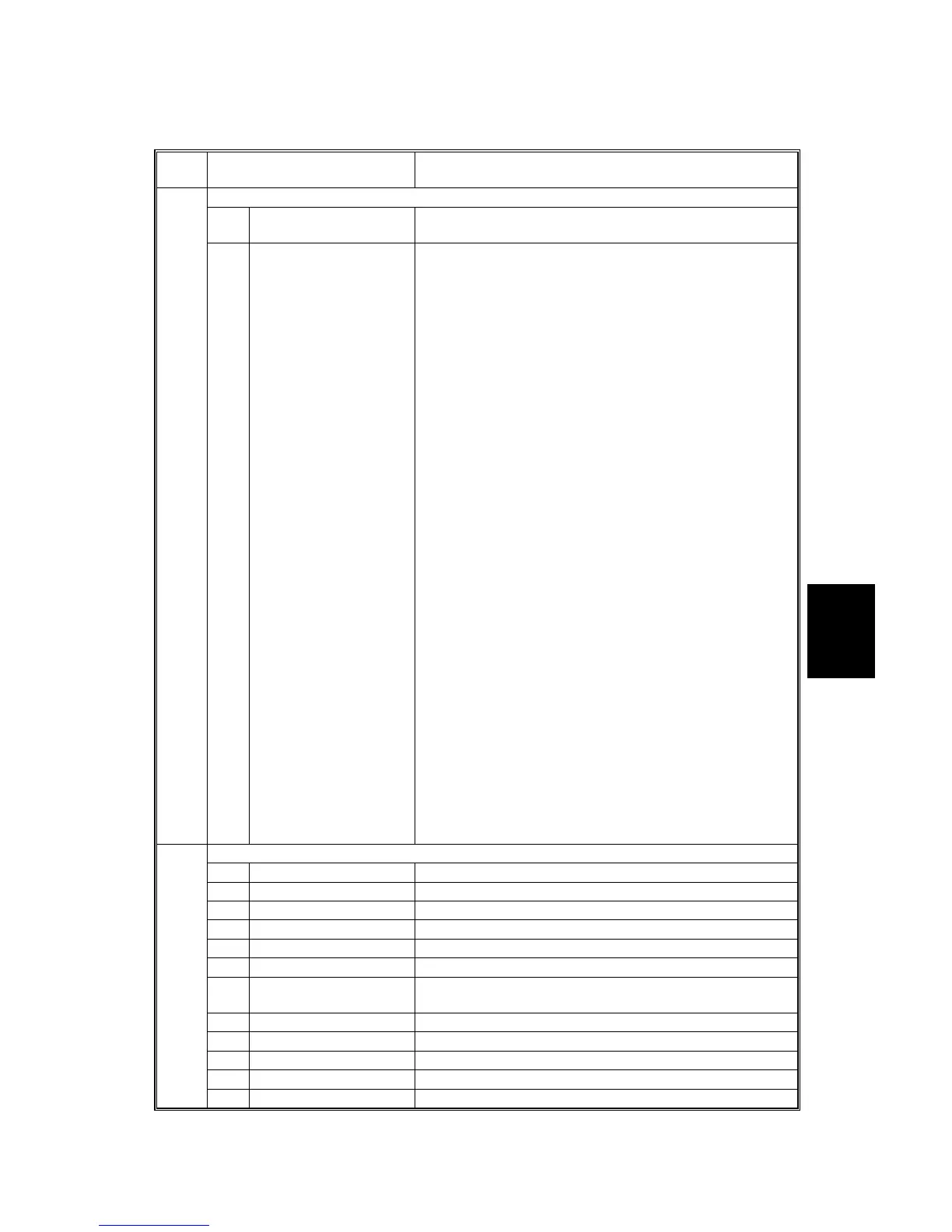

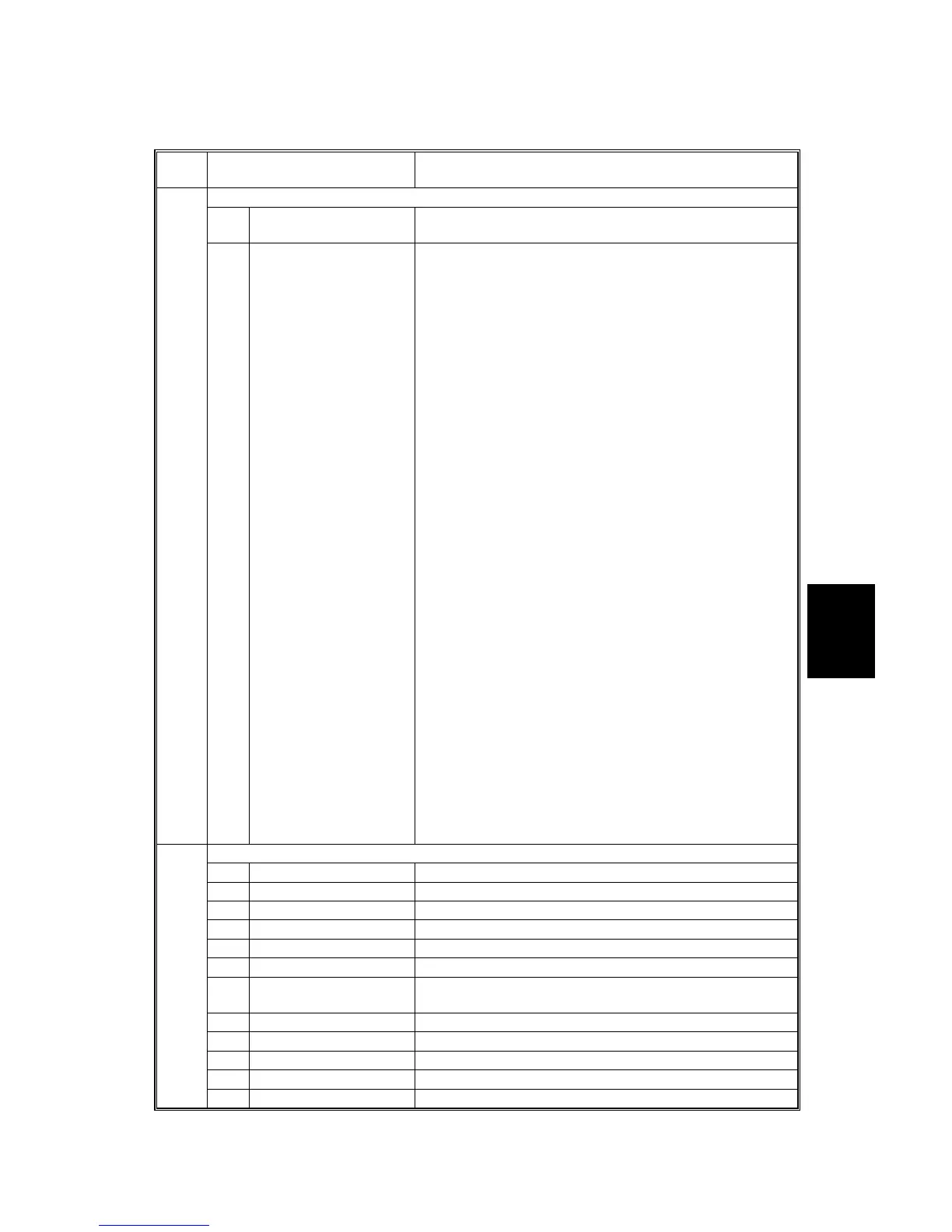

SP3-XXX: (Process)

3

Mode No.

(Class 1, 2, and 3)

Function / [ Setting ]

Process Control

1 Execute

Does a forced process control, and displays the result as

one of the following codes.

001

2 Display Displays the completion code.

• 0: Normal termination

• 103: Error (ID sensor inactive

→

Defective ID sensor,

Defective circuit, Defective BCU board)

• 104: Error (ID sensor unable to receive light

→

Defective OPC belt, Dirty OPC belt, Defective ID

sensor, Defective circuit, Defective BCU board)

• 105: Error (ID sensor unable to receive reflection from

OPC

→

Same as “104”)

• 110: Error (Cyan: ID sensor unable to detect correct

image)

• 111: Error (Magenta: ID sensor unable to detect

correct image)

• 112: Error (Yellow: ID sensor unable to detect correct

image)

• 113: Error (Cyan: ID sensor unable to detect correct

image)

• 114: Error (Magenta: ID sensor unable to detect

correct image)

• 115: Error (Yellow: ID sensor unable to detect correct

image)

• 116: Error (Black: ID sensor unable to detect correct

image)

• 118: Error (Black image not detected)

• 123: Error (Development bias error; Black ID sensor

unable to detect correct image)

Solutions for codes 110 to 123:

• Poor connection to the development unit

• Dirty development bias terminal

• Abnormal development bias

• PCU not installed correctly

• LD unit defective

• Abnormal charge corona voltage

• Defective BICU

Process Control DFU

1 LED

[0 ~ 255 / 150 / 1 /step]

2 Bk Out

[0 ~ 0xFFFF / 0 / 1 /step]

3 Bk Led Off Out

[0 ~ 0xFFFF / 0 / 1 /step]

4 Color Out

[0 ~ 0xFFFF / 0 / 1 /step]

5 Color Led Off Out

[0 ~ 0xFFFF / 0 / 1 /step]

6 ID Sensor Target

[0 ~ 5000 / 1500 / 1 /step]

7

ID sensor Out

Adjustment

[800 ~ 12000 / 1000 / 1 /step]

10 Bk Vg Control

[0 ~ 1000 / 250 / 1 /step]

11 Color Vg Control

[0 ~ 1000 / 400 / 1 /step]

12 Color Vd Control

[0 ~ 1000 / 150 / 1 /step]

13 gamma M

[–30000 ~ 30000 / 2000 / 1 /step]

002

14 gamma C

[–30000 ~ 30000 / 2000 / 1 /step]

Loading...

Loading...