110 ZXP Series 9 Card Printer Service Manual P1086708-001

Theory of Operation

Printing Technologies and Ribbons

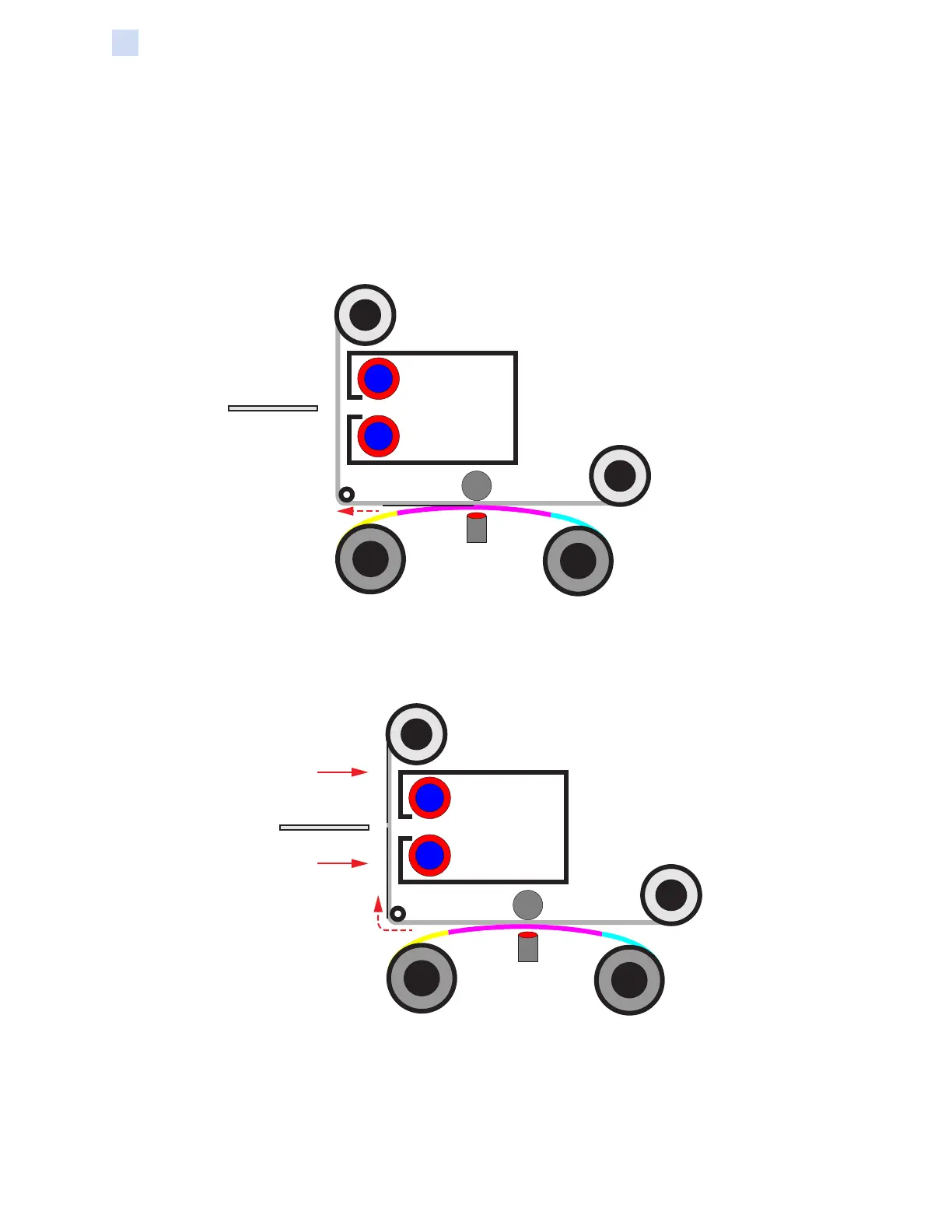

Retransfer Process

Unlike direct-to-card printing, in which images are printed directly onto the surface of the card,

retransfer printing is a four-step process:

Step 1. The card image is printed onto a thin lm, called intermediate transfer media (INTM).

This INTM has a special transfer layer to hold the image. Note that the card images

are printed in reverse.

Card

Preinthead

Transfer film

take-up

Heated transfer

rollers

Transfer Station

Transfer film

supply

Print ribbon

supply

Print ribbon

take-up

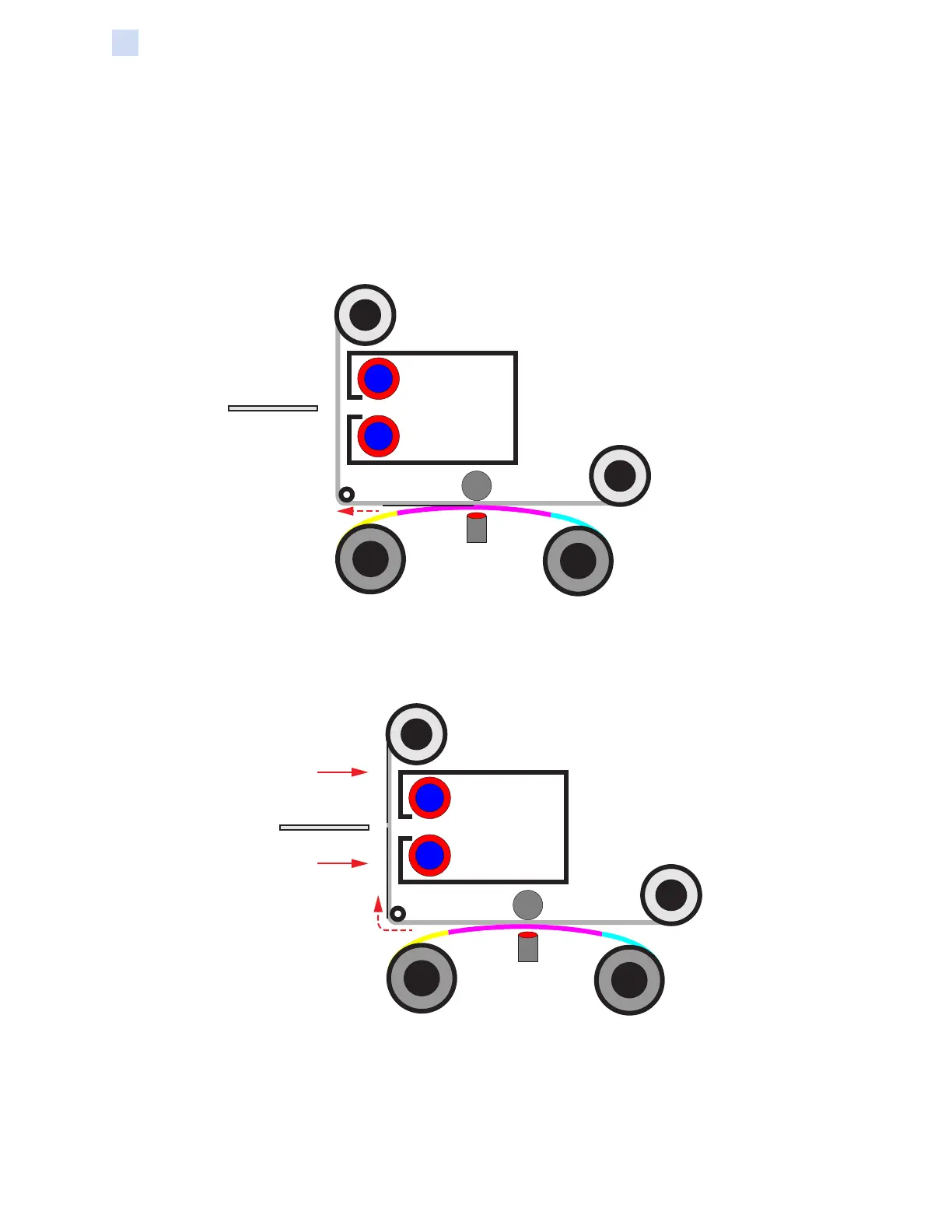

Step 2. The card images on the transfer lm are moved to the transfer station.

Card

Card Image

(top)

Card Image

(bottom)

Printhead

Transfer film

take-up

Heated transfer

rollers

Transfer Station

Transfer film

supply

Print ribbon

supply

Print ribbon

take-up

Loading...

Loading...