P1086708-001 ZXP Series 9 Card Printer Service Manual 151

Setting Custom Card Specications

Adjustments

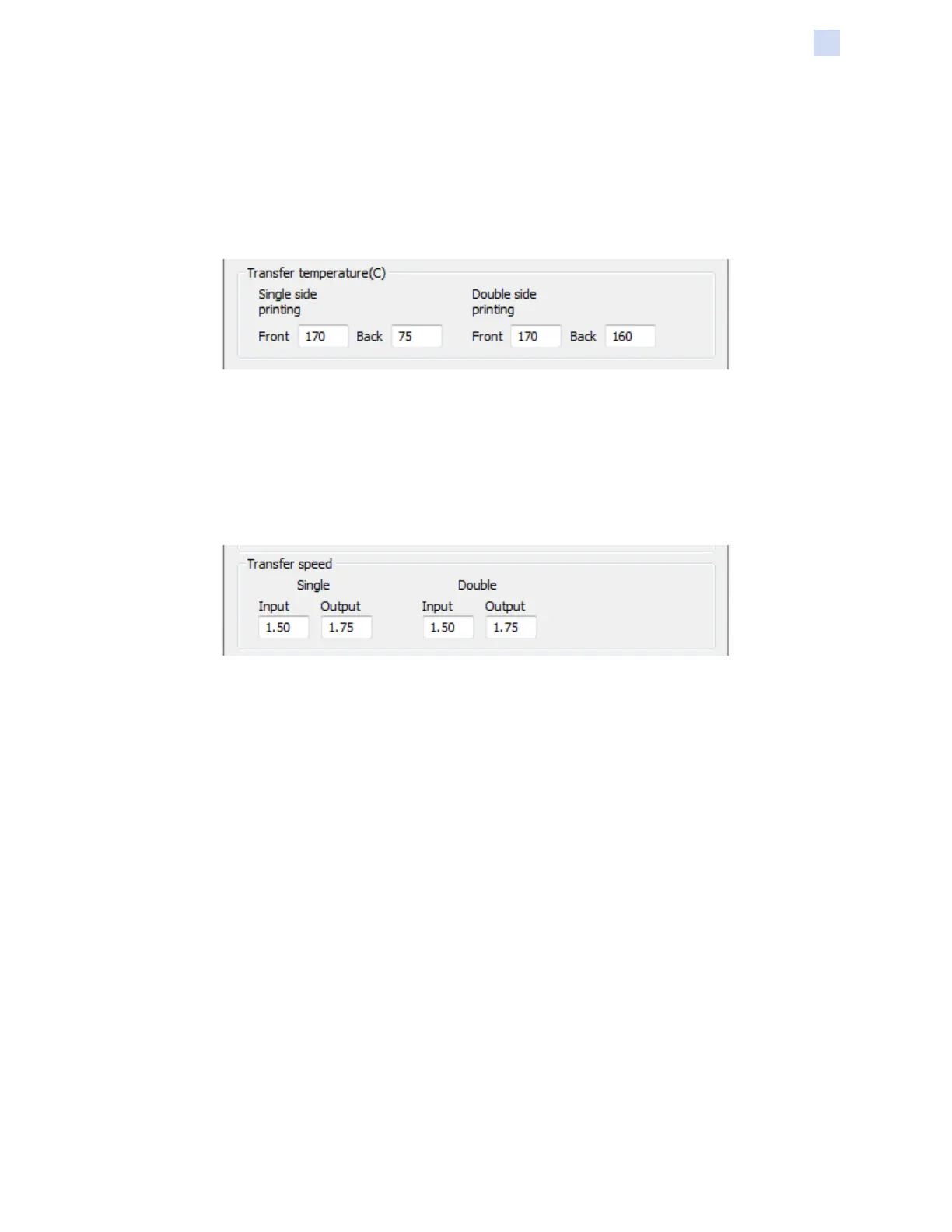

Transfer Temperature

Transfer temperature is controlled by increasing or decreasing the value in one degree increments.

However, changing values in less than ve degree increments will take signicantly more time in

establishing the correct card specication. Values are entered for both single- and double-sided

printer congurations, and for the front and back of the card independently (in the case of double-

sided printing).

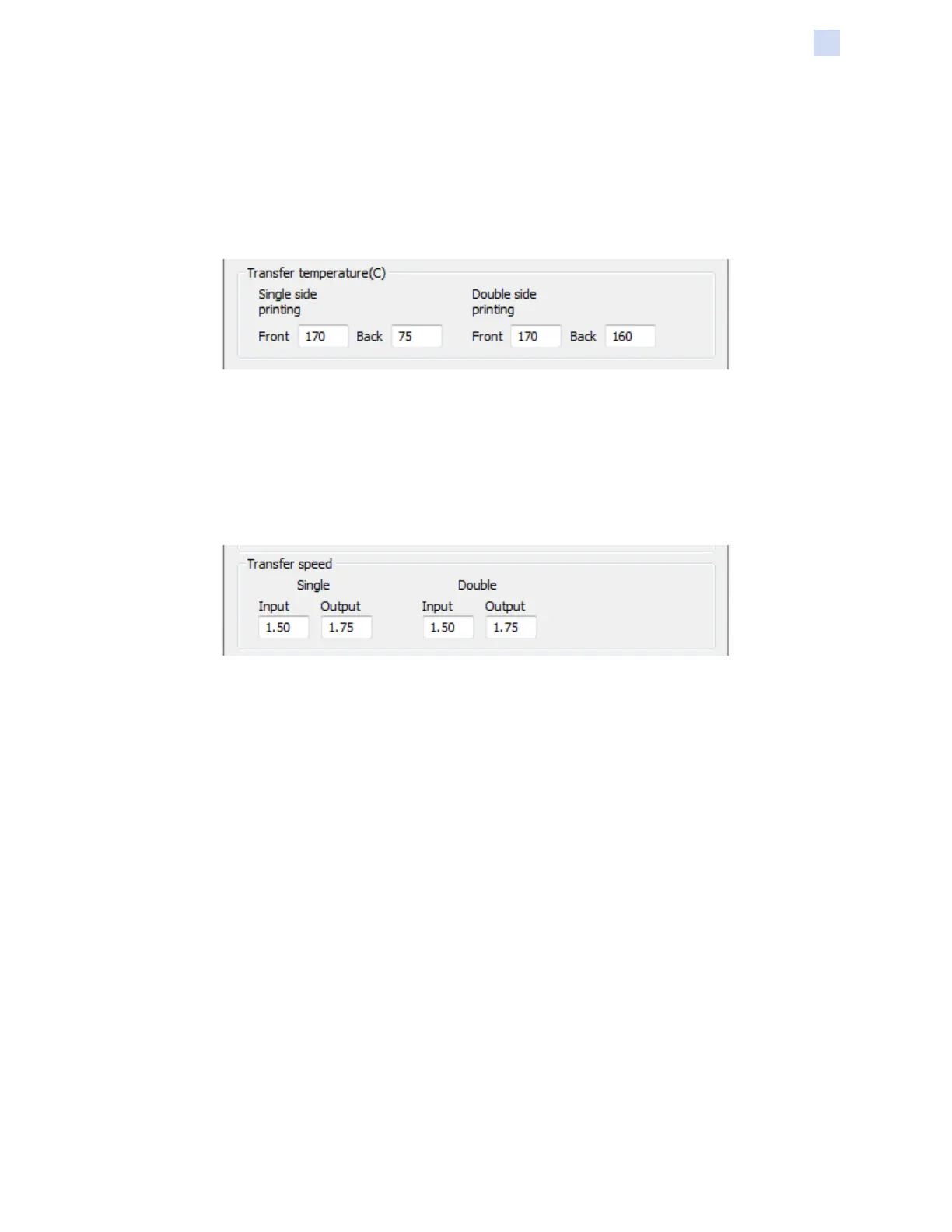

Transfer Input and Output Speed

Transfer input speed controls the speed in which the card enters the transfer station in inches per

second (IPS), to an accuracy of one one-hundredth (0.01) of an inch. However, changing values in

less that ve one-hundredth (0.05) of an inch increments will take signicantly longer in establishing

the correct card specication. Values are entered for both single- and double-sided printer

congurations, and for the input and output speeds independently.

Additional considerations and information

The thermal conductivity of the card—or from what and how the card is made—fundamentally

inuences re-transfer performance. Card characteristics affecting re-transfer include:

y Single- vs. multi-layer construction: for single-layer cards, warp is often lowest when

equal energy is put into each side of the card, while such is not usually true for multi-layer

cards made of a mix of metals and plastics due to the widely different thermal properties of

the materials;

y Surface nish: glossy vs. matte;

y Magnetic stripe: more prone to warp, especially low-coercivity (LoCo) cards identiable by a

brown stripe instead of the common high-coercivity black stripe;

y Smart card: often containing asymmetrically-distributed, thermally conductive, dissimilar

components which can make warp reduction more challenging.

Even cards sold as typical PVC may not all be similar in terms of re-transfer behavior, given their

exact binders, llers, pigmentations, and other materials ratios. While many competitive re-transfer

printers tend to discourage the use of PVC because it can be difcult to use in their re-transfer

printers, a prime ZXP Series 9 advantage is the ability to successfully re-transfer to economical PVC

cards.

Loading...

Loading...