2

-58

Apr. 2007

DSC48

417W2C0A

417W2B9A

► INJECTION NOZZLE

• Never come in contact with sprayed diesel fuel under

pressure. It can penetrate your skin, causing serious

personal injury.

• Make sure nobody is in direction of the spray.

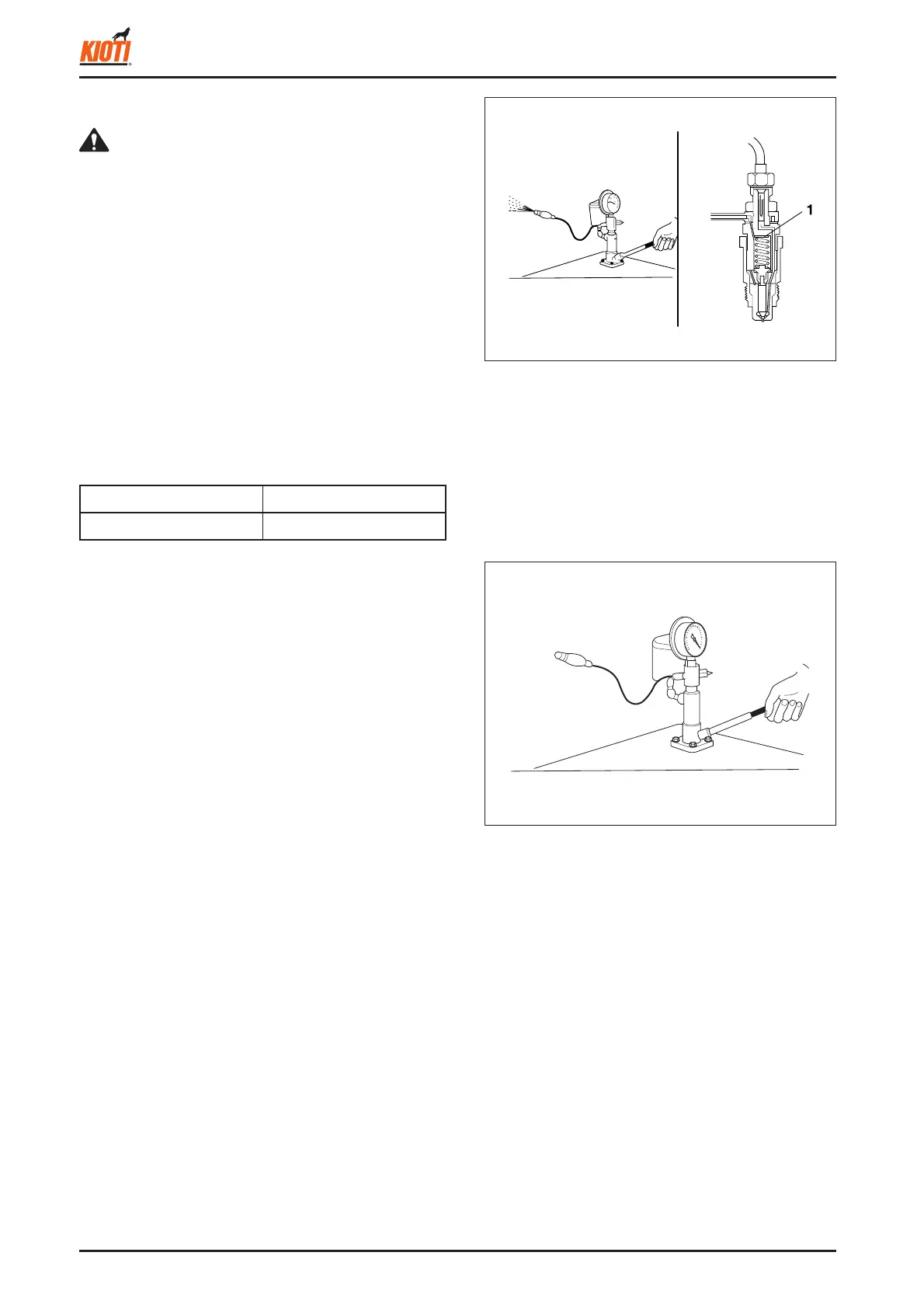

(1) Nozzle injection pressure

1. Set the injection nozzle to the nozzle tester.

2. Measure the injection pressure.

3. If the measurement is not within the factory specifi ca-

tions, adjust the pressure by removing the nozzle and

replacing the adjusting washer (1).

CAUTION

NOTE:

• Pressure variation within 0.1 mm difference of the

adjusting washer's thickness is approx. 10kgf/cm

2

.

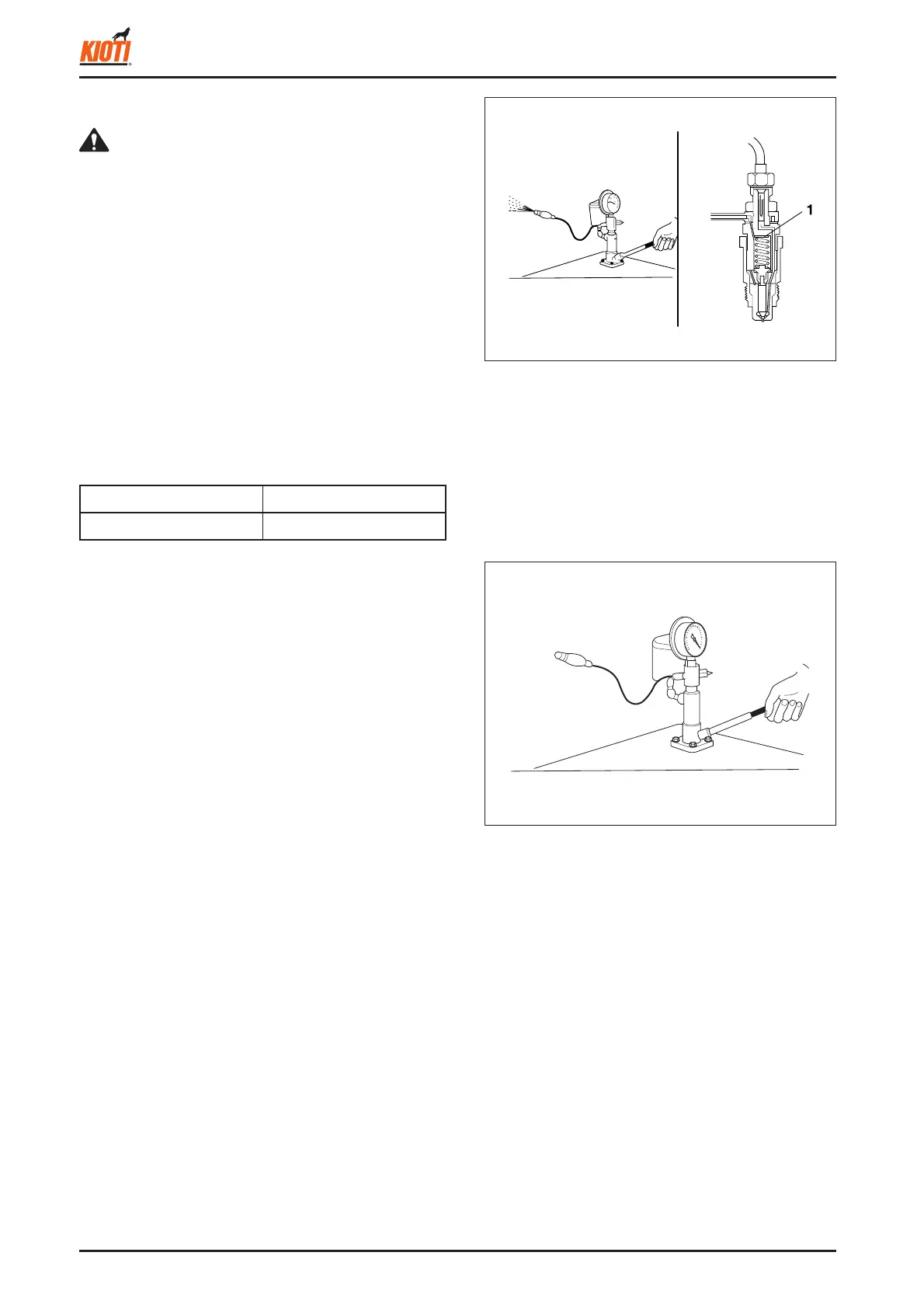

(2) Fuel tightness of needle valve seat

1. Set the injection nozzle to the nozzle tester.

2. Apply 130 kgf/cm

2

of pressure for 10 seconds and

check if fuel leaks from the nozzle.

3. If the fuel leaks, replace the nozzle.

Factory spec. Allowable limit

228.5 ~ 239.0 kgf/cm

2

-

Loading...

Loading...