6

-12

Apr. 2007

DSC48

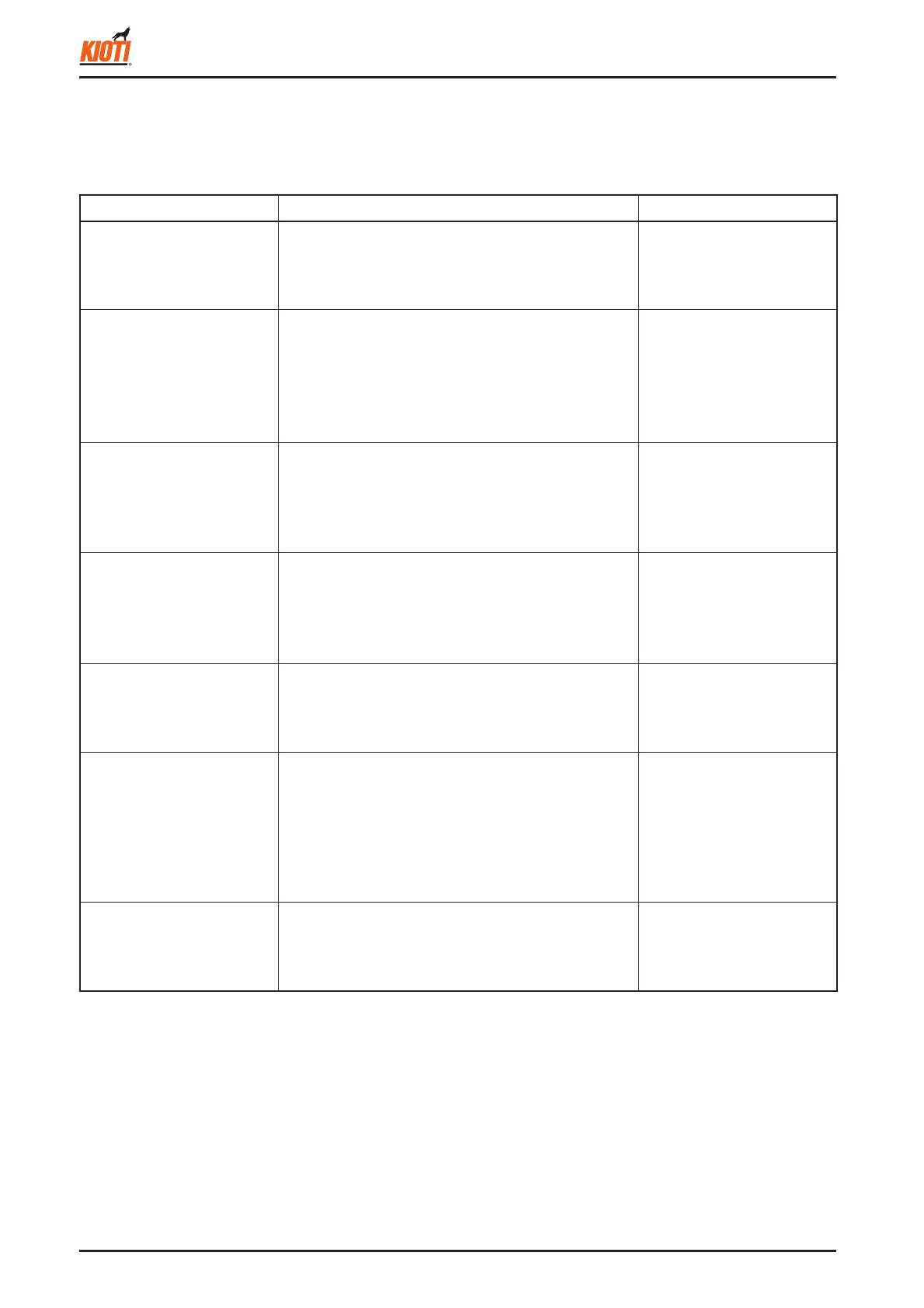

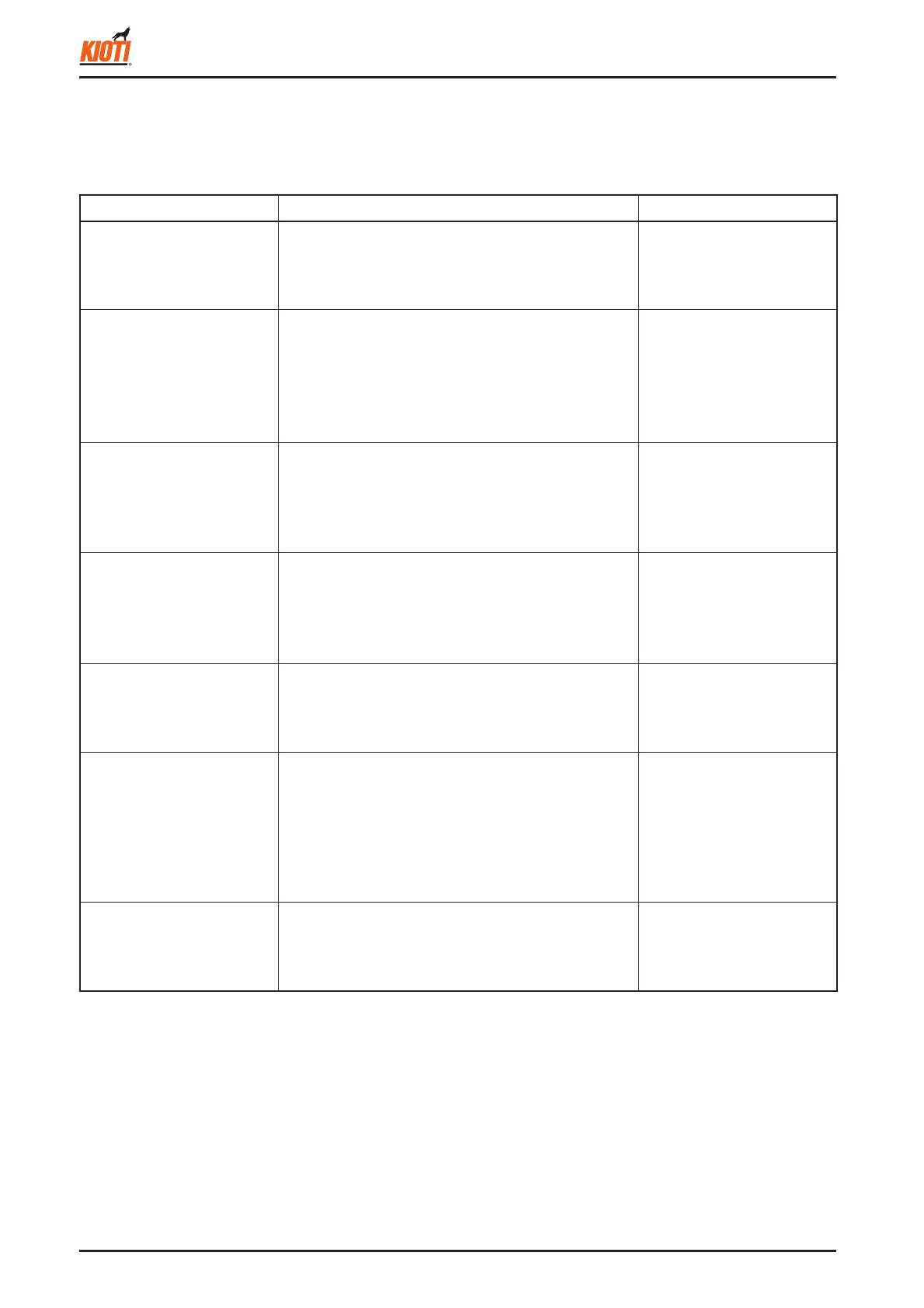

1.5.2 TROUBLESHOOTING WITH HYDRAULIC SYSTEM

If each solenoid value is correctly operating when its corresponding manual push button is pressed and if the hydraulic

system is believed to be the cause of malfunction, perform the following troubleshooting. The next system to be checked is

the electric system of each controller.

Symptom Cause Action

The cylinder does not

operate.

• Air sucked in

(suction pipe, hose, oil fi lter, etc.)

• Insuffi cient or incorrect oil level

• Clogged hydraulic fi lter

• Repair

• Replenish or replace

• Clean or replace

Only the steering cylinder

does not work. Or it takes

time to operate.

• Abnormal low pressure relief valve

• Abnormal hydraulic pump (D)

• Abnormal steering control solenoid valve

• Abnormal steering cylinder

(Worn or damaged cylinder, damaged O-ring)

• Loose or abnormal pipe or connecting system

• Repair or replace

• Replace

• Replace

• Replace

• Repair

The brake does not work

when operating the power

steering lever.

• Unadjusted power brake cable

• Abnormal low pressure relief valve

• Abnormal steering control solenoid valve

• Abnormal steering cylinder

(Worn or damaged cylinder, damaged O-ring)

• Adjust

• Repair

• Replace

• Replace

The reaping unit cannot be

lifted nor operated.

• Abnormal high pressure relief valve

• Abnormal hydraulic pump

• Loose pipe or coupler between hydraulic pump and

valve unit

• Abnormal reaping unit lifting solenoid valve

• Repair

• Replace

• Repair

• Replace

The reaping unit is

automatically lowered

without any operation.

• Abnormal reaping unit lowering solenoid valve

• Abnormal reaping unit cylinder

(Worn or damaged cylinder, damaged O-ring)

• Loose or abnormally installed pipe or coupler

• Replace

• Replace

• Repair

Abnormal noise occurs. • Relief valve in operation

(Overload- Lowly set pressure)

• Air sucked in (suction pipe, fi lter, etc.)

• Vibration occurred by pipe contact or resonance

with other parts

• Clogged hydraulic fi lter

• Damaged hydraulic pump

• Check and repair

• Repair

• Repair

• Clean or replace

• Replace

Oil temperature is

abnormally high.

• Leaked hydraulic fi lter (worn or damaged)

• Oil leak from control valve

• Relief valve in operation

(Overload-Lowly set pressure)

• Replace

• Repair or replace

• Repair or replace

Loading...

Loading...