Apr. 2007

2

-57

DSC48

417W2B7A

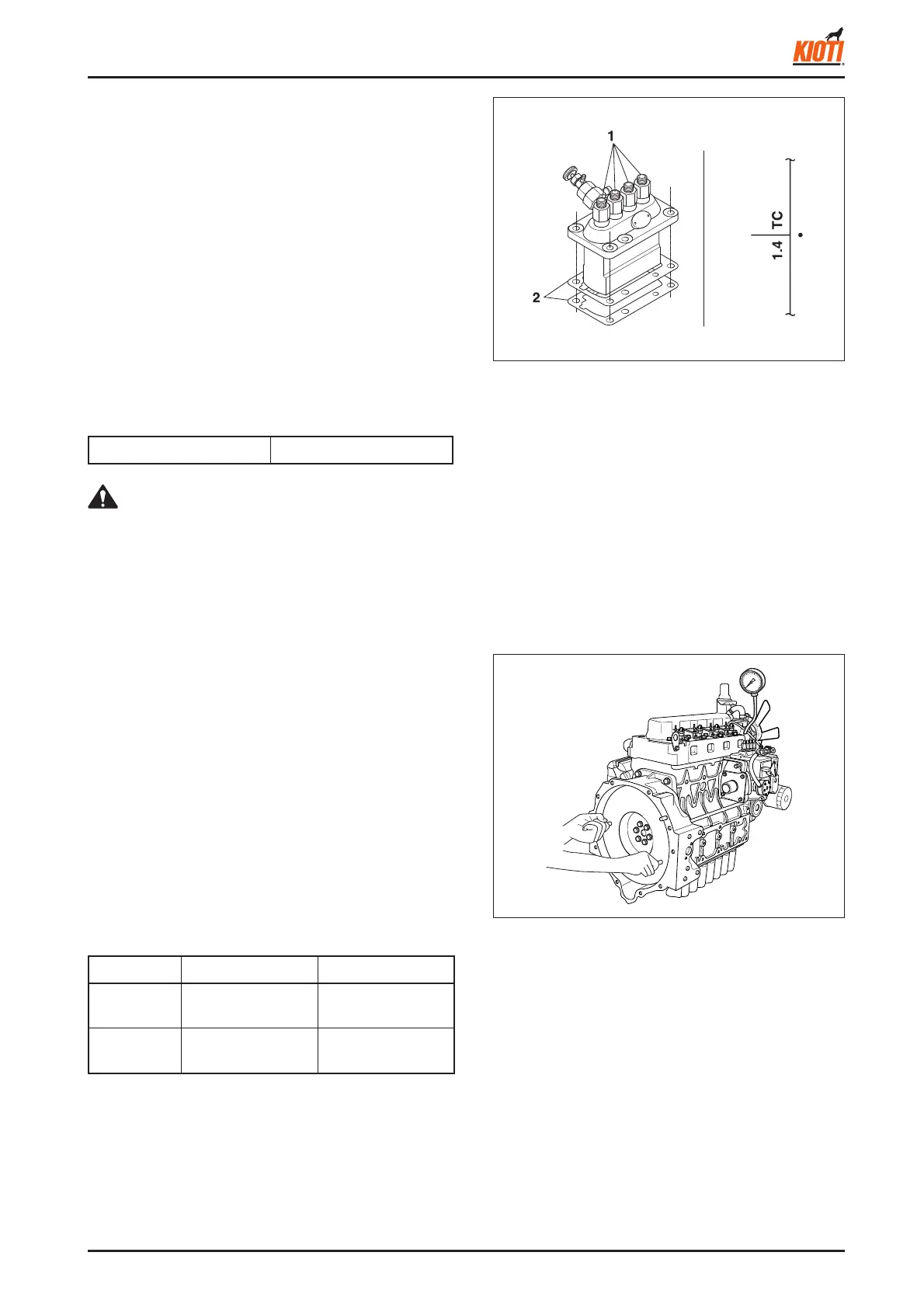

(1) Delivery valve holder (2) Shim

3.3.7 FUEL SYSTEM

A. CHECKING AND ADJUSTING

► INJECTION PUMP

(1) Injection timing

1. Remove the injection pipe.

2. Set the speed control lever to the maximum fuel dis-

charge position.

3. Turn the fl ywheel counterclockwise (facing the fl ywheel)

until the fuel level reaches the hole of the delivery valve

holder (1).

4. Turn the fl ywheel further and stop turning when the fuel

overfl ows. Then, check the injection timing.

5. If the Fl mark does not align with the mark of the win-

dow on fl ywheel housing, add or remove the shim(s) (2)

to adjust.

• Apply a liquid gasket to the shim when reassembling.

CAUTION

<Reference>

• The timing advances by removing the shim and retards

by adding the shim. One shim (0.15 mm) corresponds

to approx. 1.5° of crank angle.

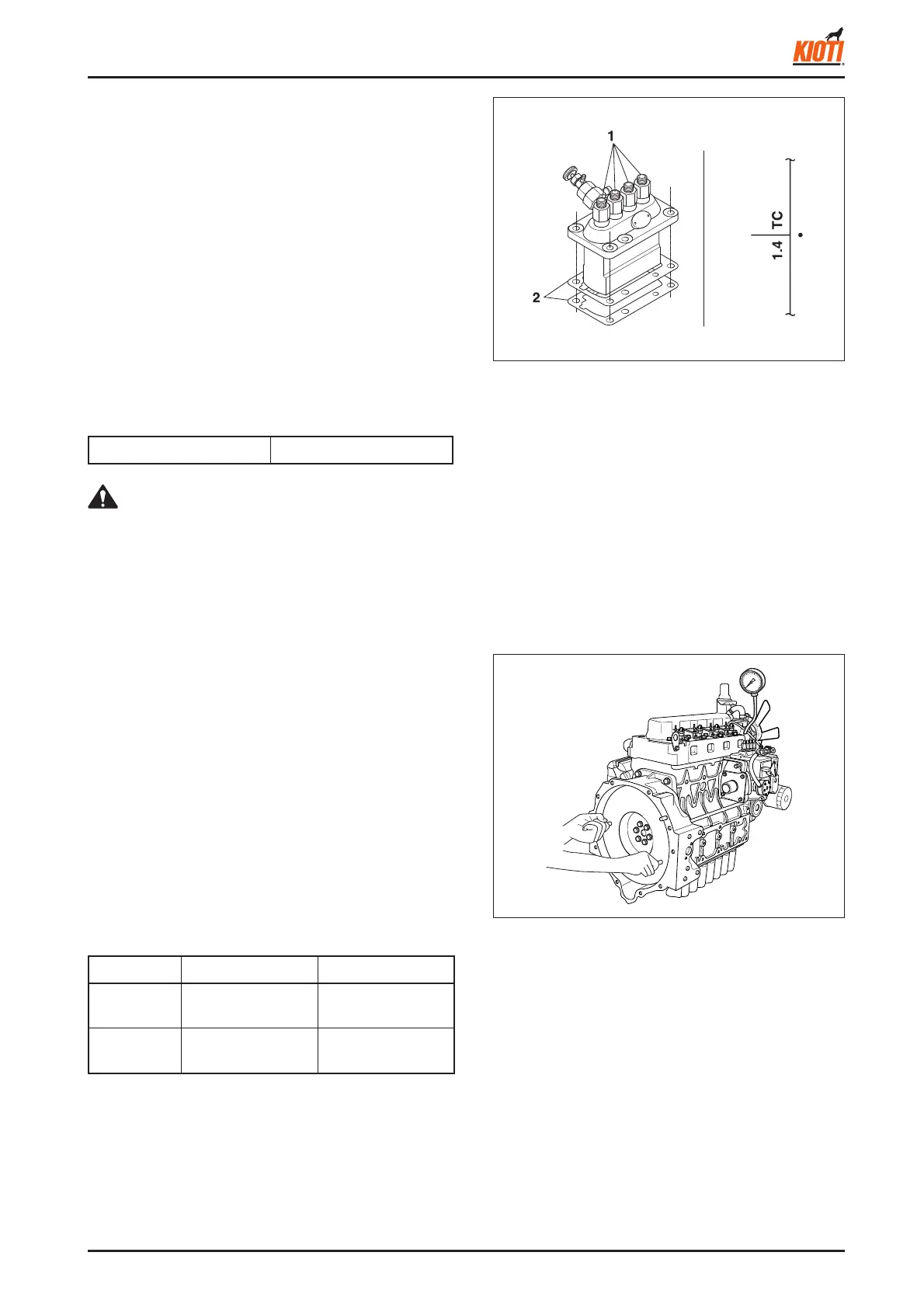

(2) Delivery valve fuel tightness

1. Remove the injection pipes, glow plugs and inlet mani-

fold. And install a pressure tester.

2. With the speed control lever at the fuel injection posi-

tion, turn the crankshaft counterclockwise (facing the

fl ywheel) until the pressure builds up to the fuel injec-

tion pressure.

3. Release the pressure in the delivery chamber by mov-

ing down the plunger to the bottom dead center (turn

the crankshaft clockwise approx 90° from the FI timing).

4. If the pressure drops more than the allowable limit

within 5 seconds, replace the delivery valve or pump

assembly.

5. If the pressure does not rise, replace the pump element

with new one and test again.

417W2B8A

Injection timing 18°

Factory spec. Allowable limit

Fuel injection

pressure

150 kgf/cm

2

-

Pressure

drop

- 10 kgf/cm

2

Loading...

Loading...