2

-8

Apr. 2007

DSC48

417W215A

417W214A

417W213A

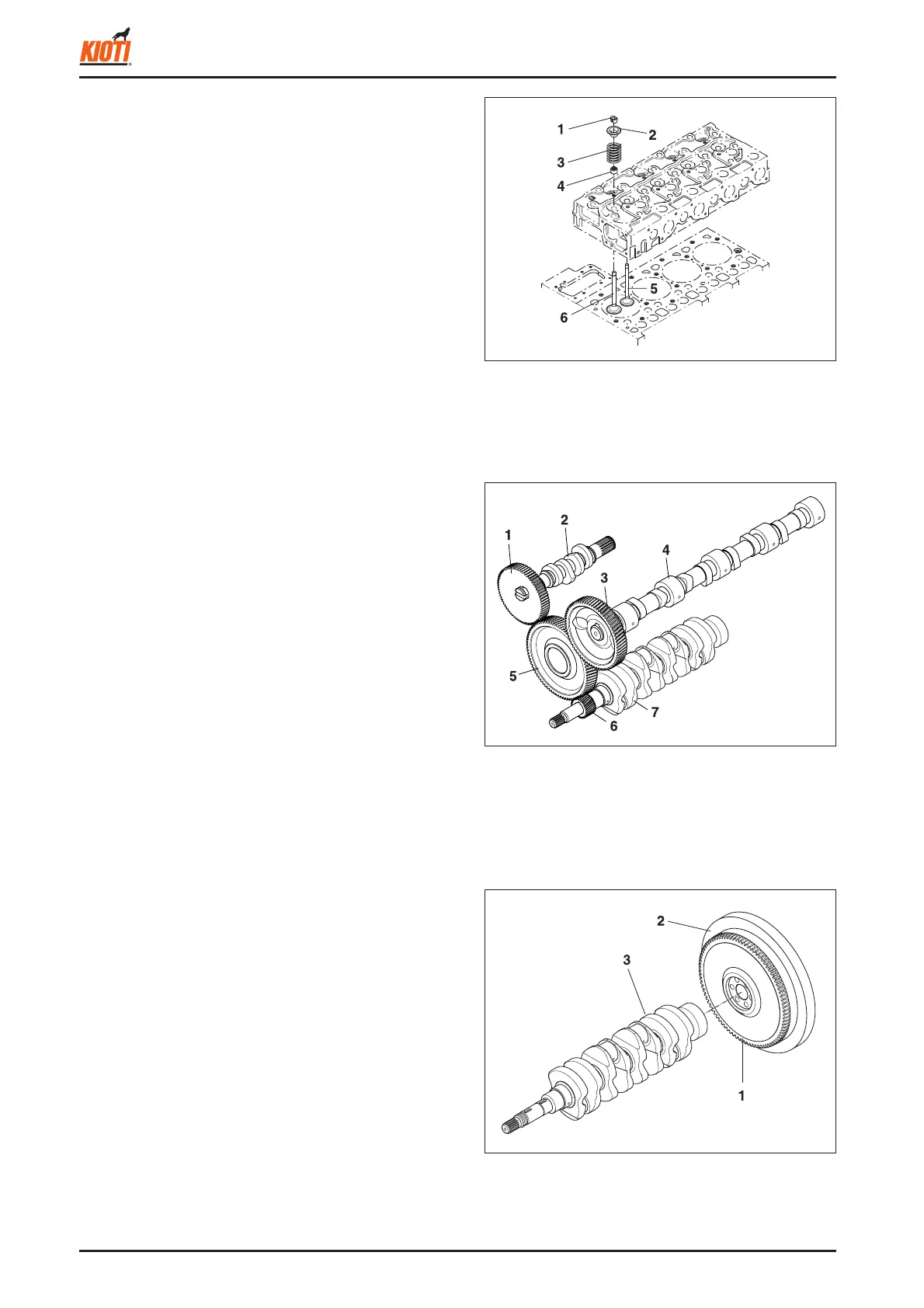

(1) Valve collet (4) Valve stem seal

(2) Valve spring retainer (5) Exhaust valve

(3) Valve spring (6) Intake valve

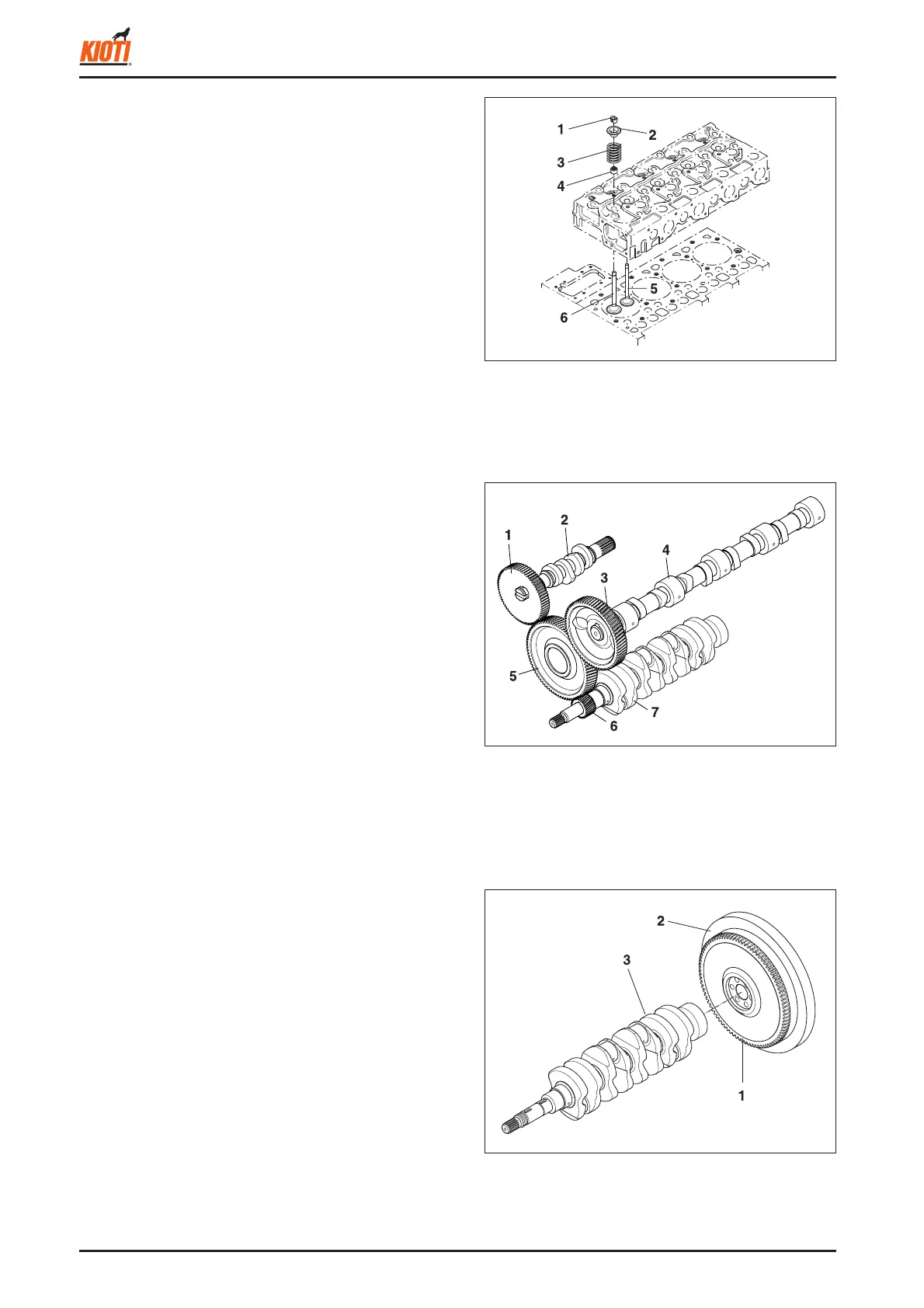

(1) Injection pump gear (5) Idle gear

(2) Fuel camshaft (6) Crankshaft gear

(3) Camshaft gear (7) Crankshaft

(4) Camshaft

(1) Ring gear

(2) Flywheel

(3) Crankshaft

2.1.11 FLYWHEEL

The fl ywheel is installed on the rear end of the crankshaft.

Its inertia keeps the engine turning at a constant speed.

while the crankshaft tends to speed up during the power

stroke and to slow down during the other strokes. The

fl ywheel has a ring gear (1), which meshes with the drive

pinion of the starter. The fl ywheel has marks "TC" and "FI"

on its outer rim. The mark TC shows the piston's top dead

center and the mark FI shows the fuel injection timing,

when they are aligned with the mark of the window on the

clutch housing.

Ú

Injection sequence

1

→

3

→

4

→

2

2.1.9 INTAKE AND EXHAUST VALVES

The valve and its guide of the intake are different from

those for the exhaust. Other parts, such as the spring (3),

spring retainers (2), valve spring collets (1), valve stem

seals (4) are the same for both the intake and the exhaust.

All contact or sliding surfaces are hardened to increase

wear resistance.

2.1.10 TIMING GEAR

The crankshaft gear drives the oil pump and rotates the

idle gear, fuel camshaft gear, and camshaft gear. The

timing for opening and closing the valves is extremely im-

portant to achieve effective air intake and suffi cient gas ex-

haust. The appropriate timing can be obtained by aligning

the marks on the crankshaft gear with the idle gear, the idle

gear with the camshaft gear, the idle gear with the injection

pump gear, when assembling.

Loading...

Loading...