1

-28

Apr. 2007

DSC48

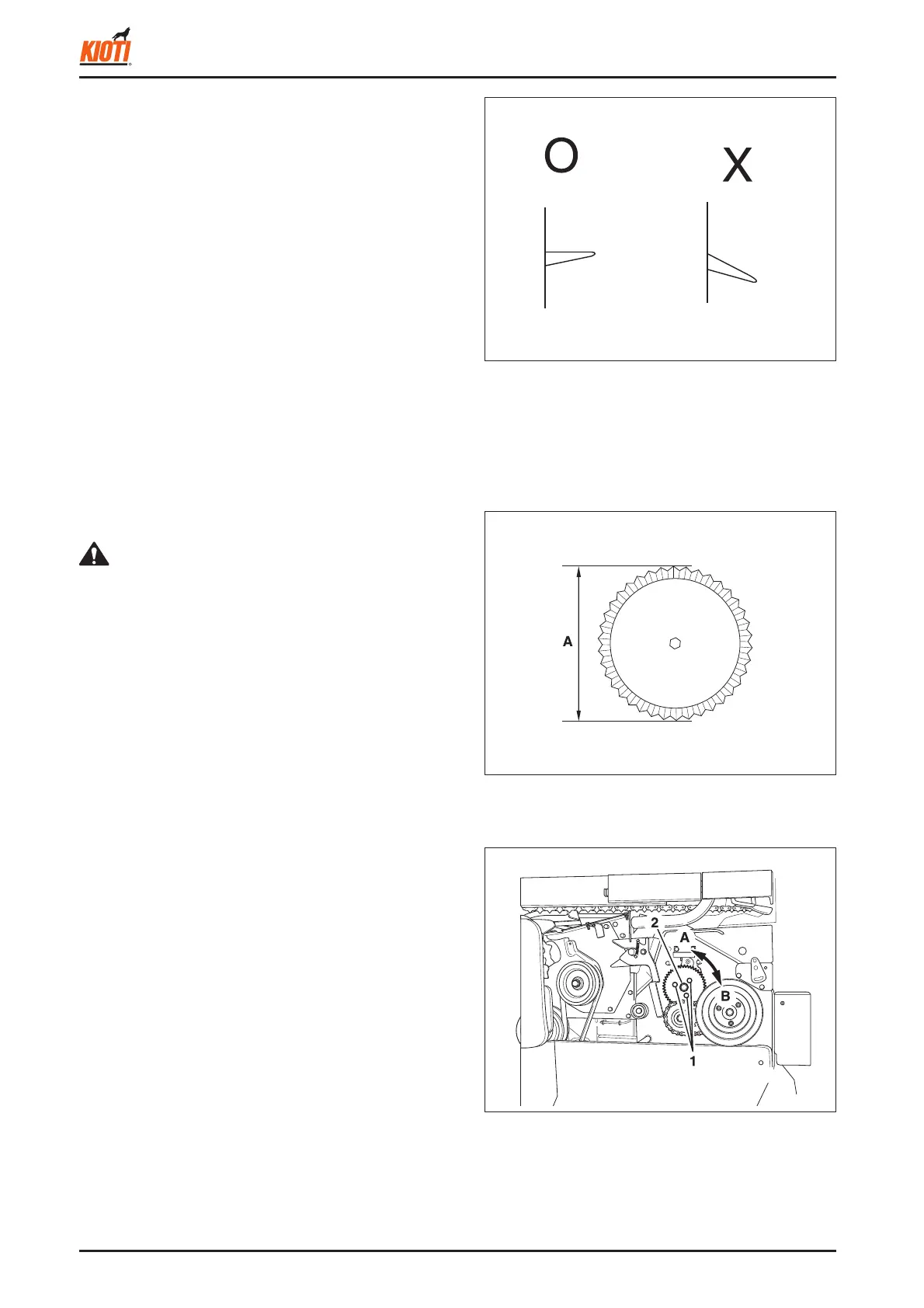

I. CHECKING CONVEYER RAKE

• Check

Check if it is deformed, worn or retracted.

• Replacement

If it is damaged or is pushed away from the guide rod or

conveyer guide

417W171A

The rake edge should be at a level with the guide.

J. ADJUSTING CLEARANCE BETWEEN CUT-

TING BLADES: see page 3-7

• Check and adjustment

Check if any blade is missing or damaged. Also check

whether the blades are properly engaged during operation.

• Replacement

If the blade is worn 1 mm or more (diameter: 2 mm)

417W172A

(A) New blade: 170 mm

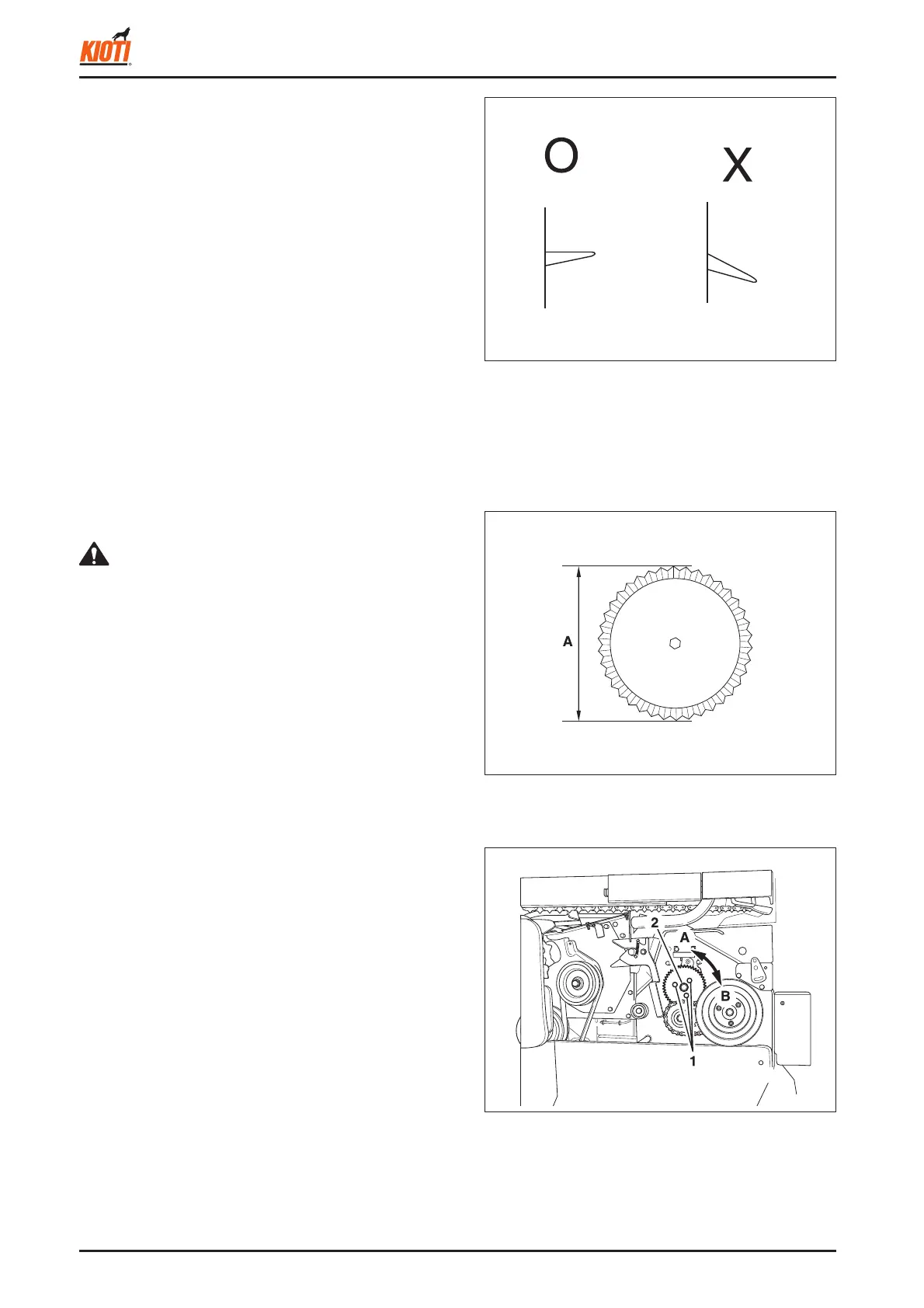

L. CHECKING CUTTING BLADE

1. Remove the side covers (LH/RH).

2. Remove the drive sprocket.

3. Remove the 180 pulley.

4. Loosen the M16 mounting bolt for the 38 gear and un-

screw the M8 bolt.

5. Turn the feeding shaft to adjust the interval.

• Right turn ...... Widen the interval

• Left turn ......... Shorten the interval

417W173A

(1) M8 bolt

(2) M16 nut

(A) Left turn: to shorten the interval

(B) Right turn: to widen the interval

K. CHECKING CUTTING DISC

• Stop the engine before checking the cutter.

CAUTION

Loading...

Loading...