104

x Pratemaking / Master Feed / Ejection Section

chap.2

Timing

When it is considered that the end mark is read under the following conditions, "CHANGE MASTER " is

displayed.

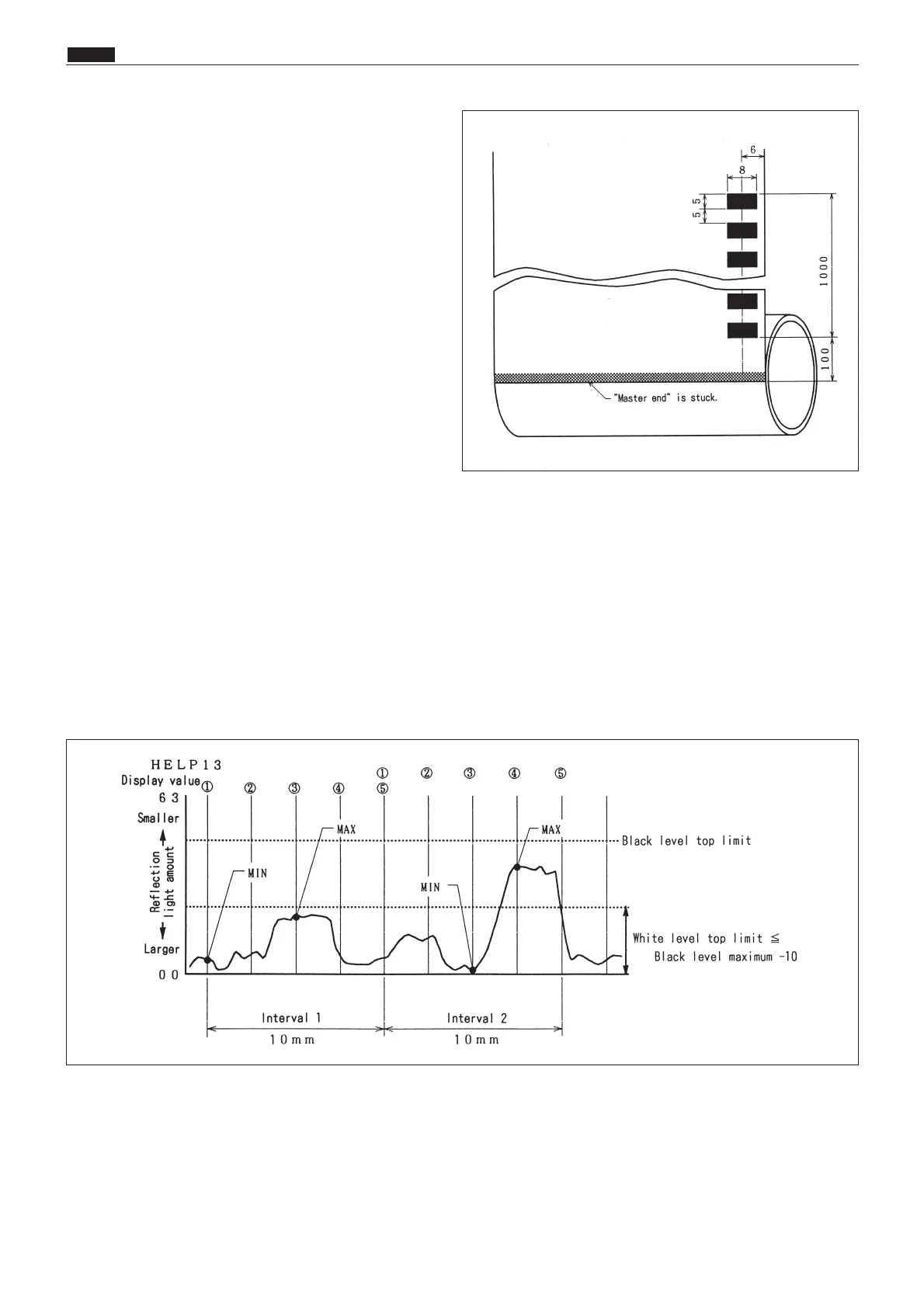

q While the master is rolling up to the drum during platemaking, the following is checked.

w The reflection light amount is read 5 times while the master passes 10 mm on the lower section of the end

mark sensor.

e When the 5 data meet the following requirements, 1 is counted.

Maximum-Minimum > 10 and Maximum

>

6

White level top limit.

r When over 7 is counted, the end mark is detected.

In the case of the above

2In interval 1, the maximum value is not over the white level, top limit counting is not conducted with MAX -

MIN > 10.

2In interval 2, the maximum value is over the white level, top limit counting is conducted with MAX - MIN >

10.

2. Master End Detection

Operation

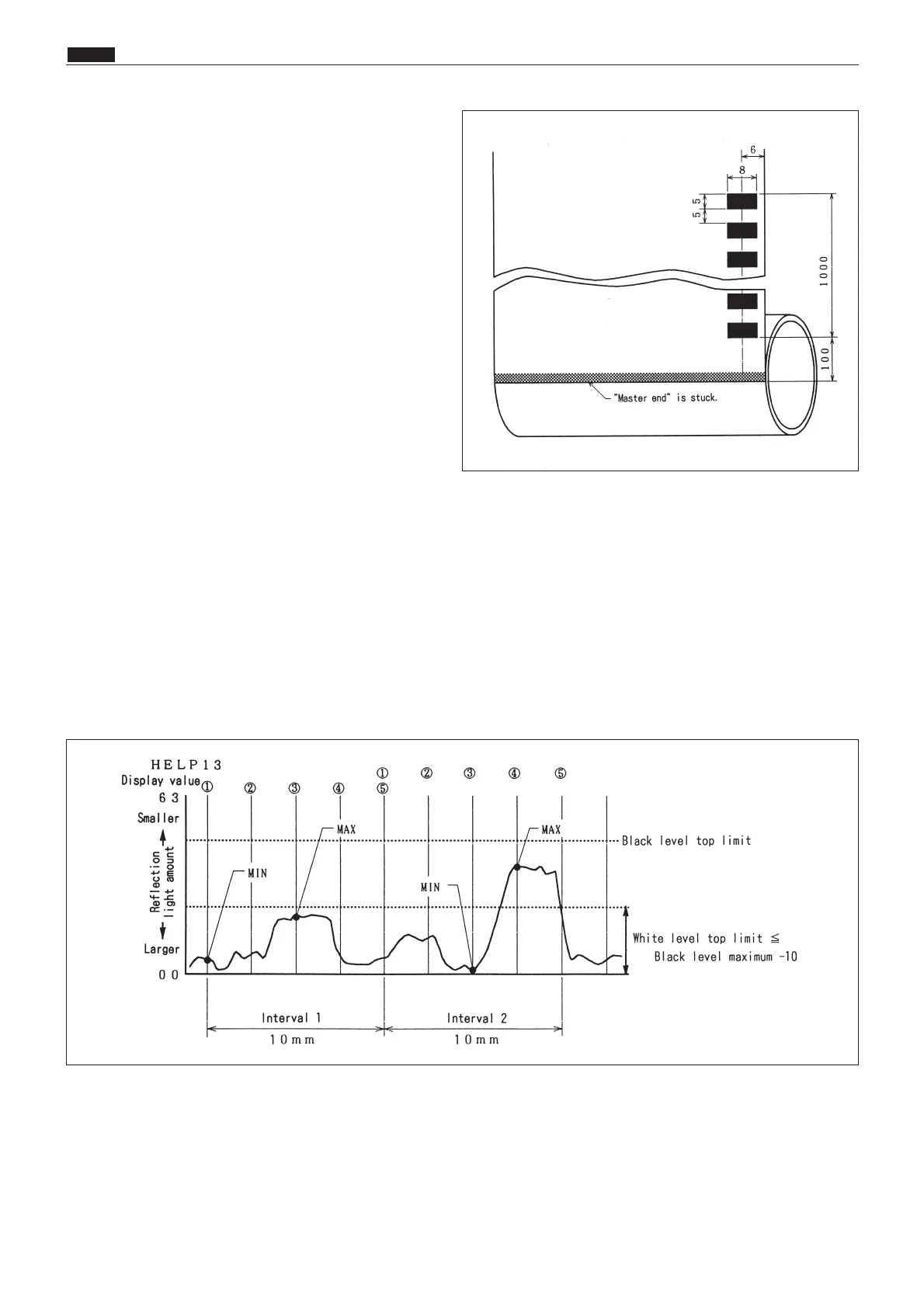

The end mark is printed on the area about 1 m from

the end of the master.

The end mark sensor detects the difference of the

reflection light amount between the end mark

(black) and the white section and performs the fol-

lowing display and operation.

2When the end mark is detected, "CHANGE MAS-

TER" is displayed.

2When "CHANGE MASTER" is displayed, plate-

making is not performed next.

2"CHANGE MASTER" is only cleared by pressing

the master set SW.

(The display is not cleared by turning the power

off.)

Loading...

Loading...