232

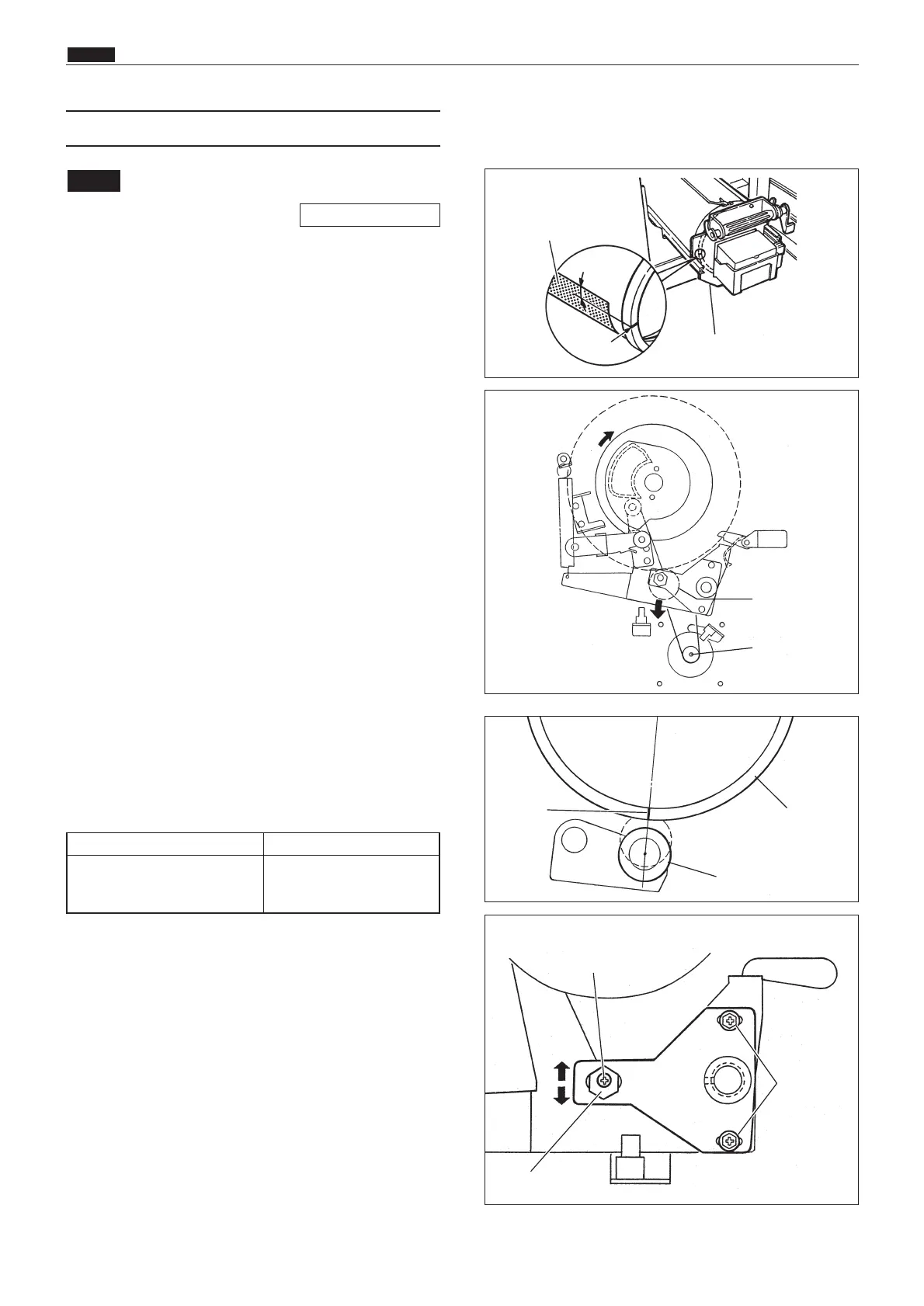

b Press Section

chap.4

20mm

Rear end of opening

Drum unit

Press roll

Main motor

shaft

Drum flange

Mark

Press roll

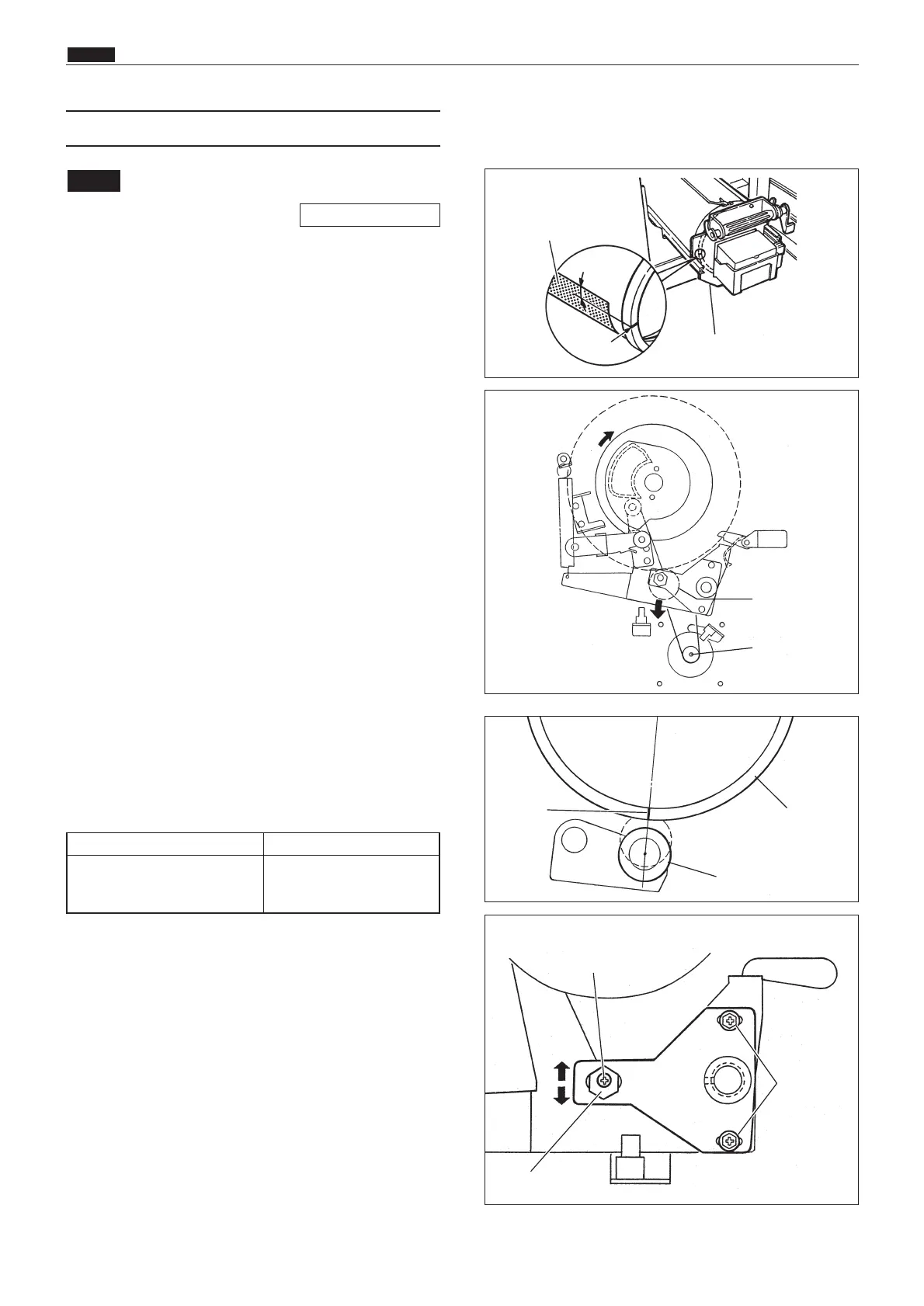

Adjust collar fixing bolt

Adjust collar

Hex bolts

Make

mark here

(2)

Adjusting the Printing Area (Press OFF Timing)

¡For description of operation.

Adjustment procedure

1) Make a mark on the end surface of the drum

flange, in a position 200 forward (in the direction

of the forward end) from the rear end of the

drum's opening.

2) With the press roll activated, turn the main

motor shaft by hand, and stop turning when the

press roll starts to descend (move in the direction

of the arrow).

Standard value

¡Open the front cover, and check whether the cen-

ter of the press roll is aligned with the mark

made in step 1).

NOTE

Standard valueItem

Alignment of mark on flange

end and center of press roll

±2mm

If the alignment is not correct:

1) Loosen the 2 hex bolts indicated.

2) Loosen the adjustment collar (eccentric) fixing

screw.

3) Turn the adjustment collar (eccentric) to move

the flange and adjust the alignment.

Moving the flange upward makes turning off of

the press occur later \ thereby making the

printing range longer

Moving the flange downward makes turning off

of the press occur earlier \ thereby making the

printing range shorter

\See page 135

Loading...

Loading...