227

c Paper Feed Section

chap.4

(9) Position Adjustment of Feed Cam

Before adjustment

¡Before feed cam position adjustment is per-

formed, the following adjustments must have

been correctly performed:

¡Printing range (press OFF timing) adjustment.

¡G roll escape timing adjustment.

IMPORTANT

Adjustment procedure

1) Using HELP mode H-30, set the PLATEMAK-

ING DARKNESS key to DARKER 2, then

execute test pattern 1 platemaking and printing.

Standard value

If the value is outside the standard range:

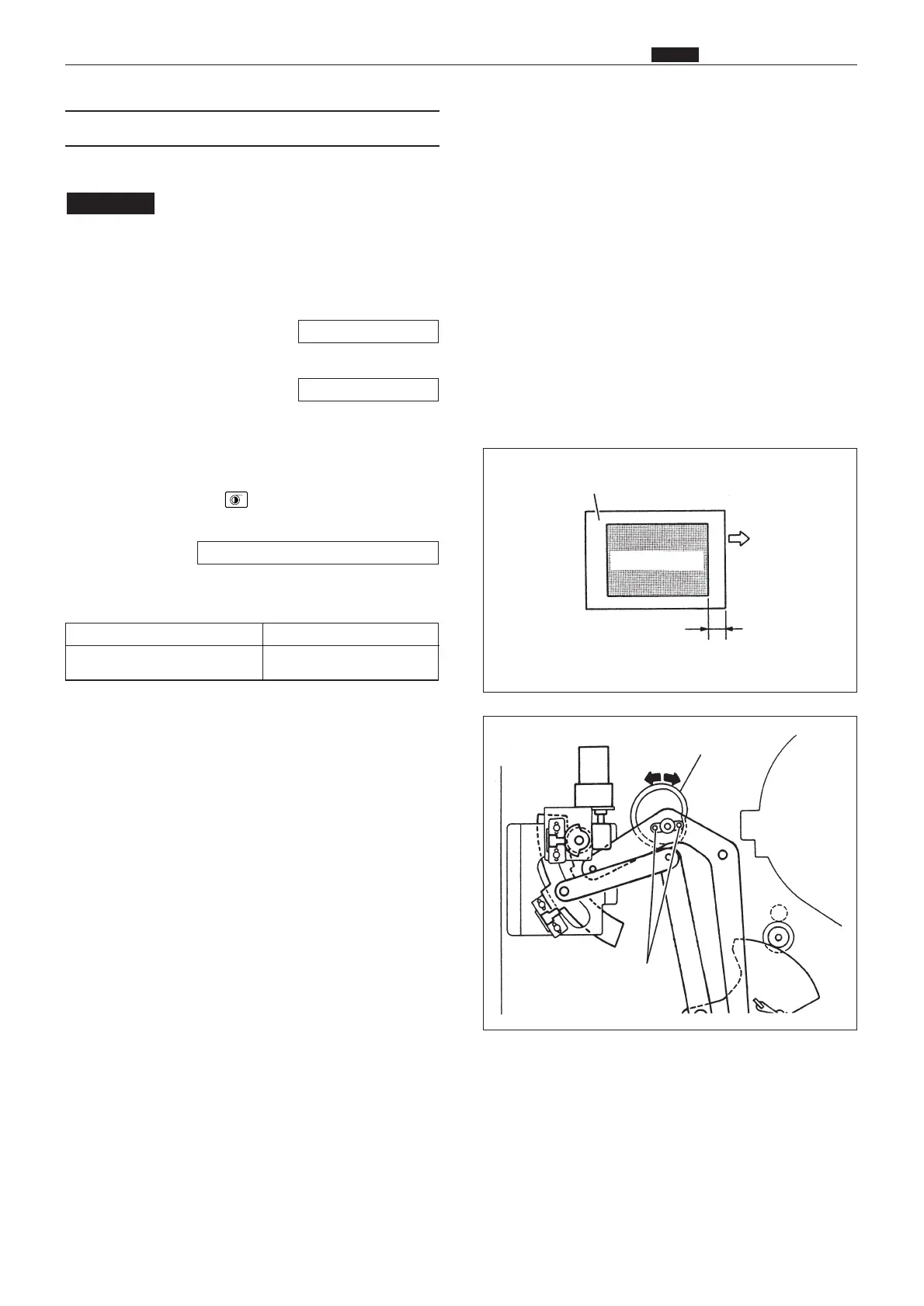

1) Turn the main motor shaft by hand, to move the

feed cam. Stop turning when the cam's fixing

screw can be seen through the adjustment hole,

so that the cam stops in that position.

2) Loosen the feed cam's 2 fixing screws, and move

the feed cam in the direction of the arrows at

right to adjust the cam's position.

[Moving the cam in this direction narrows the

leading edge margin.

\Moving the cam in this direction widens the

leading edge margin.

3) Tighten the feed cam's 2 fixing screws to fix the

cam in the adjusted position.

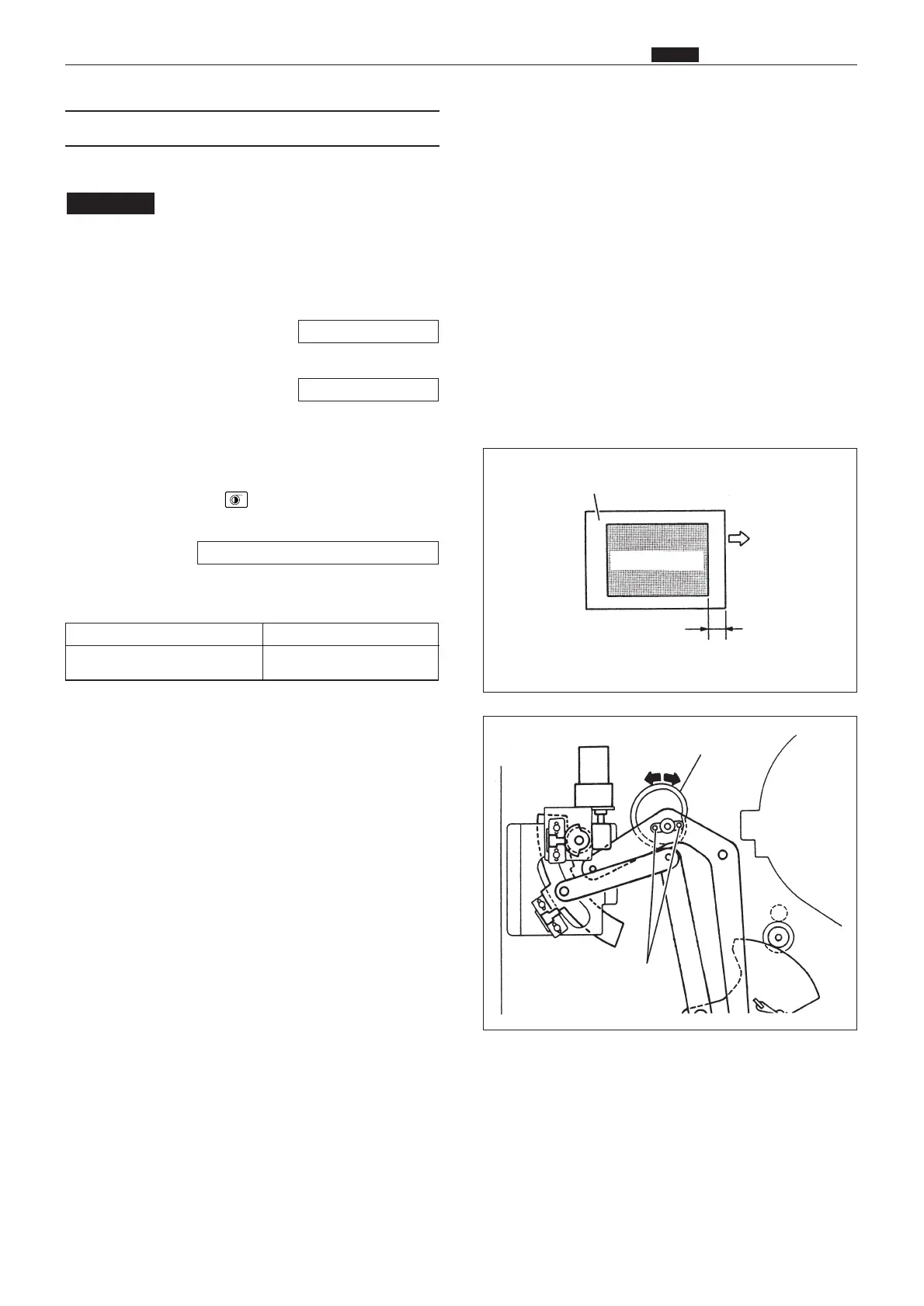

Standard valueItem

Leading edge margin

6-8mm

\See page 232

\See page 226

HELP mode H-30 \ see p.334

Fixing screws

Feed cam

Test pattern

6-8mm

Printing paper

Paper advance

direction

Loading...

Loading...