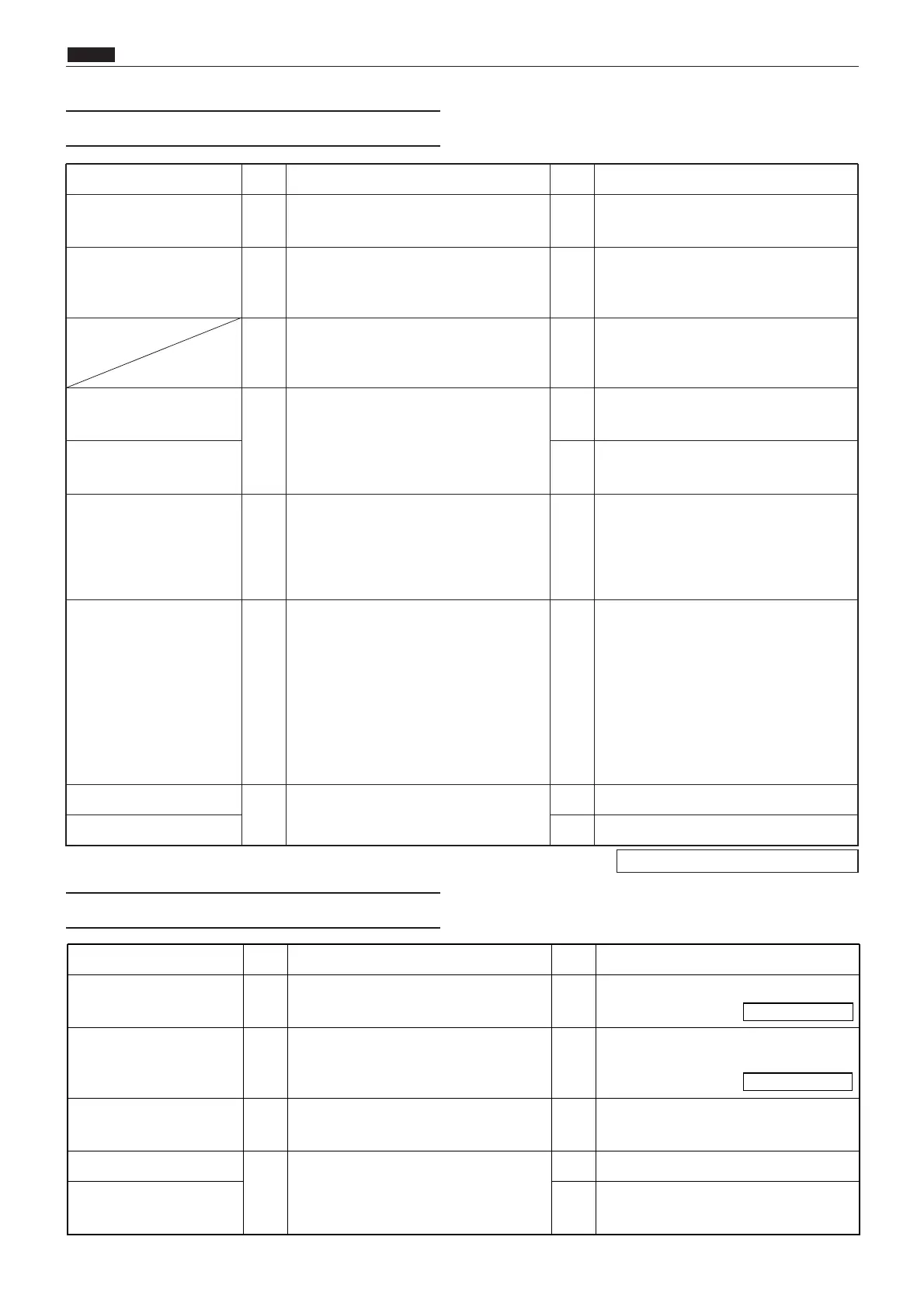

Cause/Detective section

Procedures

Result

CountermeasureItems to be checked

Master jams. 1 Does the master jam on the cutter unit? Yes Remove the jammed master.

Wire or timing belt is cut. 2

Are the wire and timing belt on the cut-

ter unit attached properly?

No Attach the wire and timing belt properly.

3

Check the cutter limit with the HELP

mode H-07*.

Is the cutter limit normal?

Yes Follow the procedure (5).

Cutter limit

4

Check the cutter limit switch with the

tester.

Is the switch turned on or off normally?

No

Replace the cutter limit (on the rear

side or front side).

Main PCB Unit Yes

Check the bundled wire and connector.

If OK, replace the main PCB Unit.

Regulated power supply 5

Remove the drive PCB Unit CN2.

Measure the voltage between the regu-

lated power supply CN2-1 (+) and CN2-

2 (GND) with the tester. Is the voltage

+24V?

No Regulated power supply.

Cutter motor 6

Check the voltage of the drive PCB Unit

CN2-17, CN2-18 with the tester when

the cutter motor relay connector is

inserted or removed.

Is the voltage +24V when the cutter

motor is moved to OPEN by the cutter

limit?

(+ or - reverse rotation depending on

the cutter motor operation direction)

Yes Replace the cutter motor.

Drive PCB Unit

7

Is the cause cleared by replacing the

drive PCB Unit?

Yes Finish

Cutter motor No Replace the cutter motor.

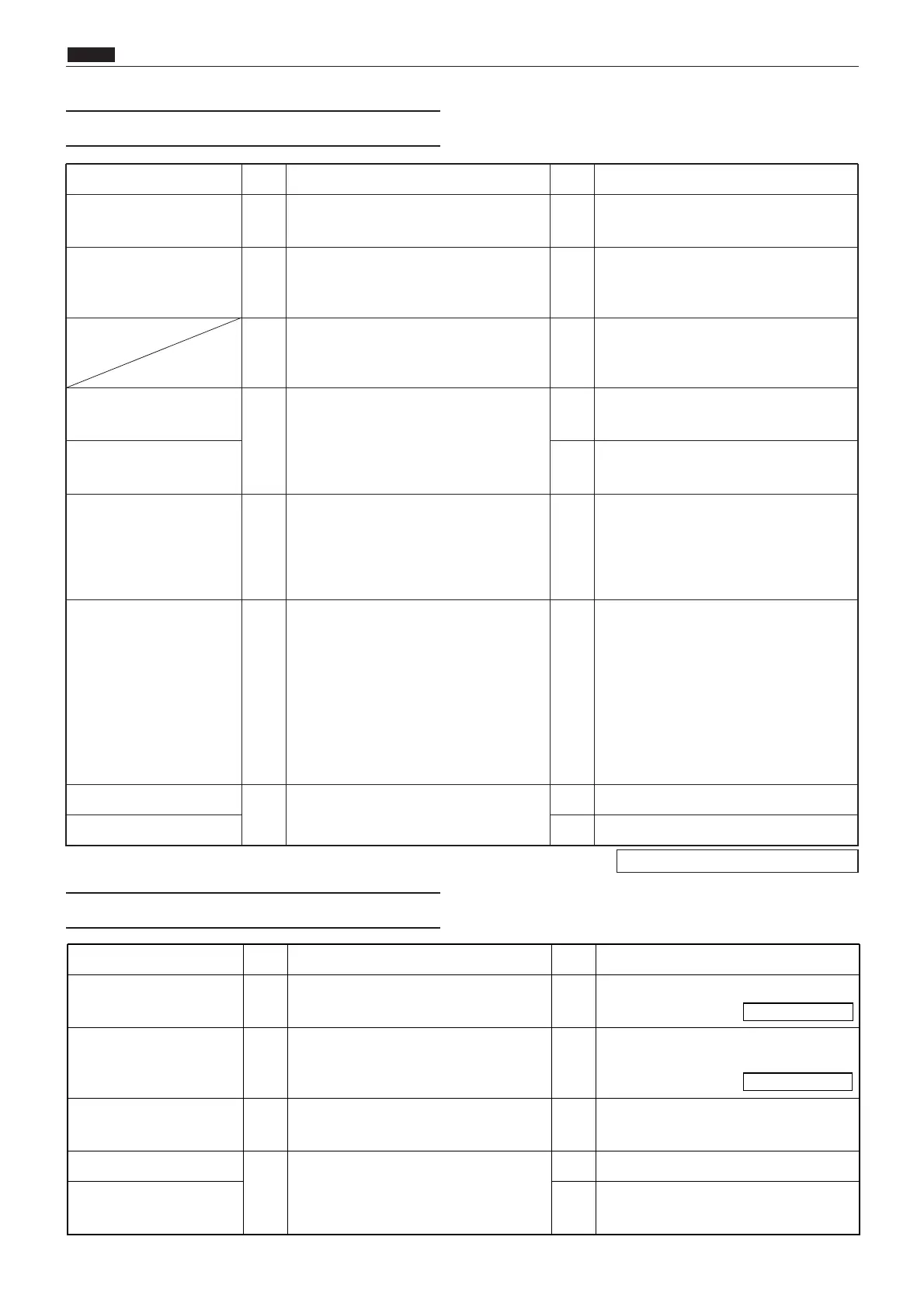

Cause/Detective section

Procedures

Result

CountermeasureItems to be checked

Lamp 1 Is lamp lit? No

See "The lamp Does not Light Up".

Optical system 2

Does the lamp advance to below the

shading plate?

No

See "The Optical System Does not

Move Forward/Backward".

Shading plate 3 Is the shading plate correctly installed? No Install the shading plate correctly.

AD PCB

4

Does replacing the AD PCB clear the

error?

Yes Finish

CCD PCB No

Adjust CCD PCB position, or replace

CCD PCB.

\See page 274

\See page 275

Loading...

Loading...